Product testing Product testing is a key link to ensure...

Winding technology

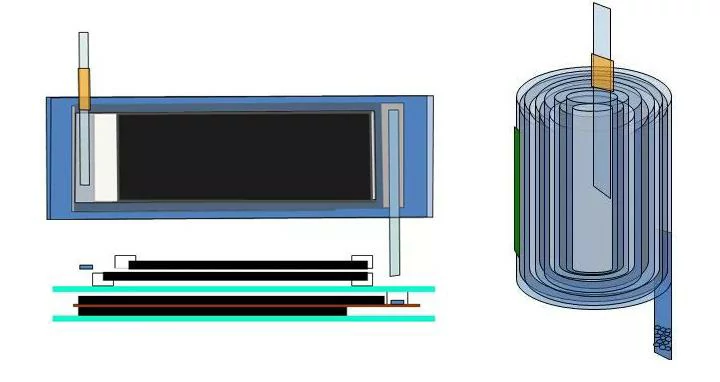

The winding process is one of the core steps in battery manufacturing, especially suitable for the production of cylindrical and flexible batteries. The process forms the core structure of the battery by alternately winding the electrode material and the diaphragm into a tight drum shape. The winding process has a direct impact on the energy density, power density, service life and safety of the battery.

Winding technology

The winding process ensures the high energy density and stability of the cell by precisely controlling the electrode material, the arrangement, tension and speed of the diaphragm. It is suitable for cylindrical and soft pack batteries and is one of the core processes to improve battery performance and production efficiency. However, this process requires highly precise control, and any slight error can affect the performance and safety of the battery, so every step of the production process needs to be strictly controlled.

Basic process

Preparation of electrodes and diaphragms

The preparation stage of the electrode material and diaphragm is the basis for ensuring high performance of the battery. The anode and cathode materials are prepared by coating, rolling, slicing and other processes, while the diaphragm ensures its function by precise manufacturing and handling. The preparation phase is critical to battery capacity, stability and safety.

The preparation stage ensures the quality of the electrodes and diaphragms, laying the foundation for subsequent winding and assembly.

Winding process

The winding process forms the core structure of the battery by alternately winding the positive electrode, the negative electrode and the diaphragm. It is important to control the tension, speed and material alignment of the winding, and accurate winding can improve the energy density and service life of the battery.

The winding process ensures a tight bond between the electrode and the diaphragm, improving the energy density, stability and performance of the battery.

Pressure adjustment

The wound cell needs to be pressure adjusted to ensure a close contact between the electrode and the diaphragm, increasing the energy density of the cell. Pressure adjustment plays an important role in battery performance, conductivity and long life.

Pressure adjustment can improve the performance and stability of the battery by optimizing the cell structure.

Treatment after winding

After the winding is completed, the cell is usually trimmed and the battery performance is tested to ensure the consistency of the shape, size and structure of the cell. During the processing process, ensuring the quality of the battery is the key to the entire production chain.

The treatment after winding ensures the consistency of the shape and performance of the cell, and provides guarantee for subsequent assembly.

low-speed car batteries

Low-speed vehicle battery is a kind of battery designed for low-speed electric vehicles, which has the characteristics of clean, environmental protection, high efficiency and economy, and is widely used in electric golf carts, low-speed electric vehicles (LSV), mobile vendors, campus transportation, cargo trucks and so on

Extended reading

Product packaging and delivery

Product packaging and delivery The packaging and delivery of battery...

Product information expansion

Product information expansion Understanding low-speed vehicle battery product information is...

Product composition

Low-speed lithium battery product composition Understanding the product composition of...

THE ESSC Brand promise

Global supply

Our products sell well all over the world, covering many countries and regions, through the global logistics network, to provide customers with convenient purchasing experience.

Rigorous quality

We adhere to the highest quality control standards to ensure every product meets industry regulations and customer expectations, earning trust through consistent excellence.

Excellent service

With a customer-centric approach, we provide prompt responses, professional support, and personalized services, aiming to deliver the best user experience and long-term value.