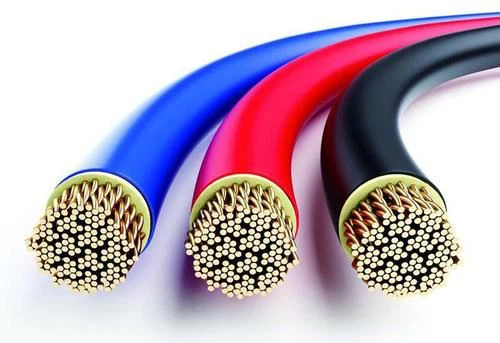

Sheath layer of DC charging pile cable The sheath layer...

What is the effect of sheet molding plastic on the shell of DC charging pile?

The use of Sheet Molding Compound (SMC) for the shells of DC charging piles offers a range of advantages. Here are six key points that illustrate the characteristics of SMC and its impact on the performance of charging piles:

main content

Material Composition

SMC stands for Sheet Molding Compound, commonly known as fiberglass material. The main raw materials consist of SMC-specific fibers, unsaturated resins, low-shrinkage additives, fillers, and various additives.

Electrical Performance

SMC exhibits excellent electrical properties, which is very important for charging piles as they need to safely transmit electrical energy under various environmental conditions.

Corrosion Resistance

SMC composite materials demonstrate good corrosion resistance, able to withstand the erosion of oils, acids, alkalis, and other chemicals. This is particularly important for the long-term outdoor use of charging piles.

Lightweight and Design Flexibility

SMC is lightweight and offers easy and flexible engineering design, allowing the charging pile shell to be shaped into complex forms while maintaining structural strength and stability.

Mechanical Properties

The mechanical properties of SMC can rival those of some metal materials, making it widely used in various industries including electrical, electronics, vehicles, construction, chemicals, and aerospace

Aging and Weather Resistance

SMC materials have strong aging and weather resistance, with a lifespan significantly longer than that of plastics. It is reported that charging pile shells made from this material can be used outdoors for decades without damage in Japan.

In summary, SMC composite materials are an ideal choice for the shells of DC charging piles due to their superior electrical properties, corrosion resistance, lightweight nature, design flexibility, mechanical properties, and aging and weather resistance.

DC CHARGING PIlE SERIES

DC charging pile is an efficient charging facility for electric vehicles, which uses direct current (DC) to directly charge the vehicle battery, significantly reducing the charging time. Compared with traditional AC charging piles, DC charging piles are able to provide higher power output and can usually charge an EV to 80% of its capacity in 30 minutes, providing users with a convenient charging experience.

Extended reading

What are grounding contact made of?

What are grounding contact made of? Grounding contacts are typically...

About security modules in card readers

About security modules in card readers Main component Security module...

Power and Communication Interface of DC charging pile reader

Power and Communication Interface of DC charging pile reader Main...

THE ESSC Brand promise

Global supply

Our products sell well all over the world, covering many countries and regions, through the global logistics network, to provide customers with convenient purchasing experience.

Rigorous quality

We adhere to the highest quality control standards to ensure every product meets industry regulations and customer expectations, earning trust through consistent excellence.

Excellent service

With a customer-centric approach, we provide prompt responses, professional support, and personalized services, aiming to deliver the best user experience and long-term value.