Battery sealing ring With the rapid development of modern science...

What is the difference between dry single - pull process and dry double - pull process?

Dry double drawing process and single drawing process are two kinds of drawing process commonly used in polymer film production. They have significant differences in process principles, stretching directions, and material properties.

Stretch direction

In the single-pull process, the film is stretched in only one direction. It is usually longitudinal stretching, that is, stretching in a straight line.

In the dry double drawing process, the material is stretched and oriented in both directions, usually lengthwise and transversally.

Process flow

The single drawing process generally includes the steps of raw material extrusion, unidirectional drawing, and heat setting. Its operation is relatively simple and low cost, but it can only improve the performance in one direction.

The dry double drawing process is more complex than the single drawing process and involves simultaneous bidirectional drawing, which usually requires more advanced equipment and more complex control techniques. Its production efficiency and technical requirements are usually high, and it is also necessary to control the stretching temperature and proportion.

Material properties

The advantages of dry method are relatively simple process, high added value, no environmental pollution; The disadvantage is that the pore size and porosity are difficult to control, and the product can not be made very thin.

The advantages of wet method are that the diaphragm aperture range is relatively small and uniform, the biaxial tensile strength is high, and the membrane is thinner. The disadvantages are large investment, long cycle and complex process.

Application area

In the field of power lithium battery, the dry method has a higher melting point than the wet method, and has better pressure resistance performance, so it is mainly used in energy storage, lithium iron phosphate power battery, two-wheel vehicle and other fields, and the cost is relatively lower than the wet method.

The wet process as a whole process is difficult, high precision, can obtain higher porosity and better air permeability, can produce thin, high strength and high energy density of the diaphragm, easier to meet the downstream lithium battery for thin, large capacity, high energy density demand, so the wet diaphragm is mostly used for ternary battery.

Cost and efficiency

Single pull process: Due to its simple process, low equipment investment and operating cost, it is suitable for mass production.

Double pull process: equipment investment and operation costs are higher, but the production of higher quality film, better performance, to meet the more stringent market demand.

conclusion

In summary, there are obvious differences between the dry double pull process and the single pull process in several aspects. The choice of process depends on the performance requirements of the final product and the application field. The single pull process is suitable for low-cost, mass production, while the dry double pull process is suitable for high-end products with higher performance requirements.

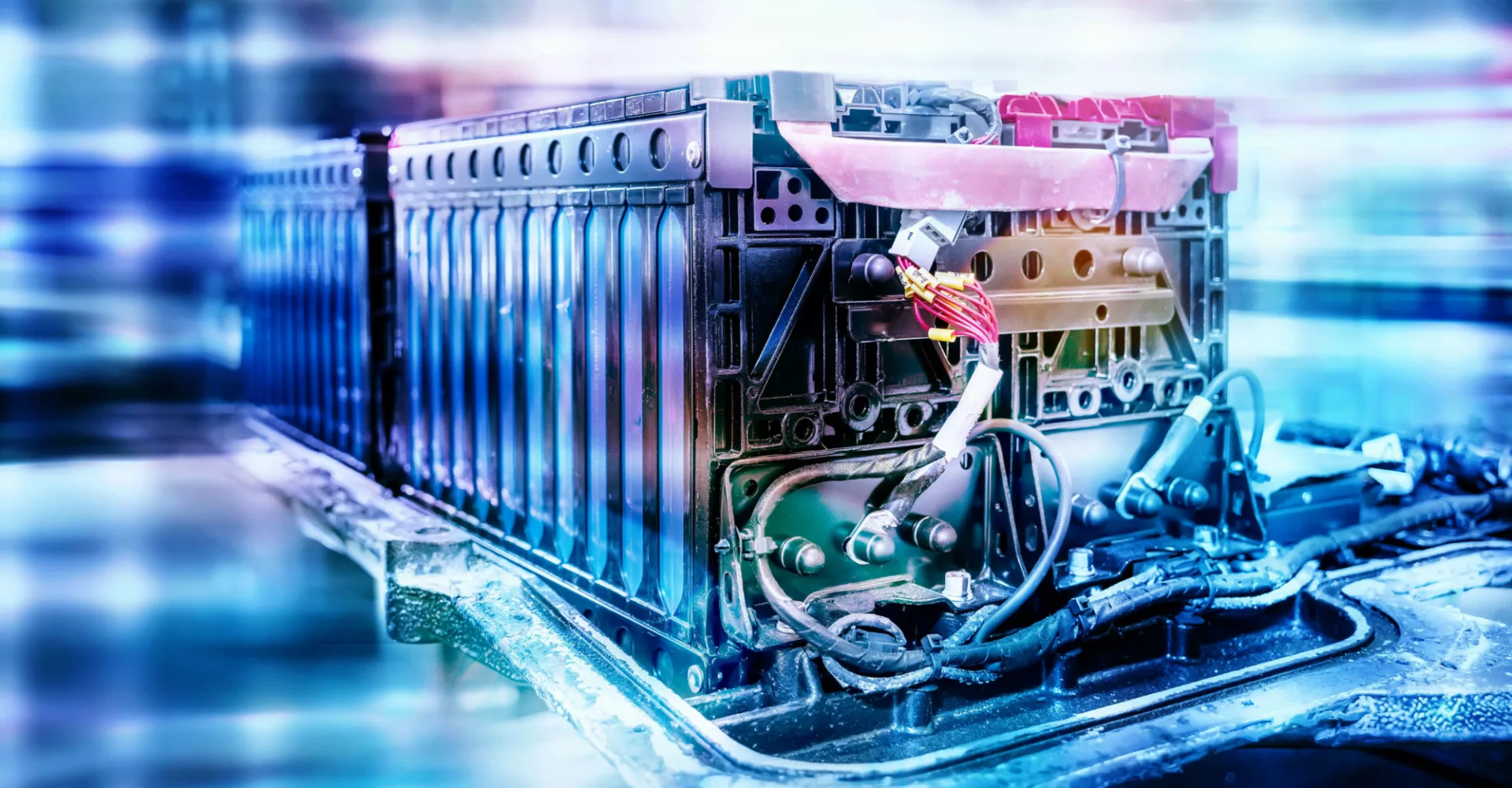

Home energy storage product series

A lithium battery pack for home energy storage systems, which is compatible with solar panels and the sun The inverter can work together with the power grid to power household appliances, and it can also be used as a For off grid systems.

Extended reading

Research on manufacturing material of negative electrode of lithium iron phosphate battery

Research on manufacturing material of negative electrode As an important...

Manufacturing process of lithium iron phosphate battery

Manufacturing process of lithium iron phosphate battery Lithium iron phosphate...

THE ESSC Brand promise

Global supply

Our products sell well all over the world, covering many countries and regions, through the global logistics network, to provide customers with convenient purchasing experience.

Rigorous quality

We adhere to the highest quality control standards to ensure every product meets industry regulations and customer expectations, earning trust through consistent excellence.

Excellent service

With a customer-centric approach, we provide prompt responses, professional support, and personalized services, aiming to deliver the best user experience and long-term value.