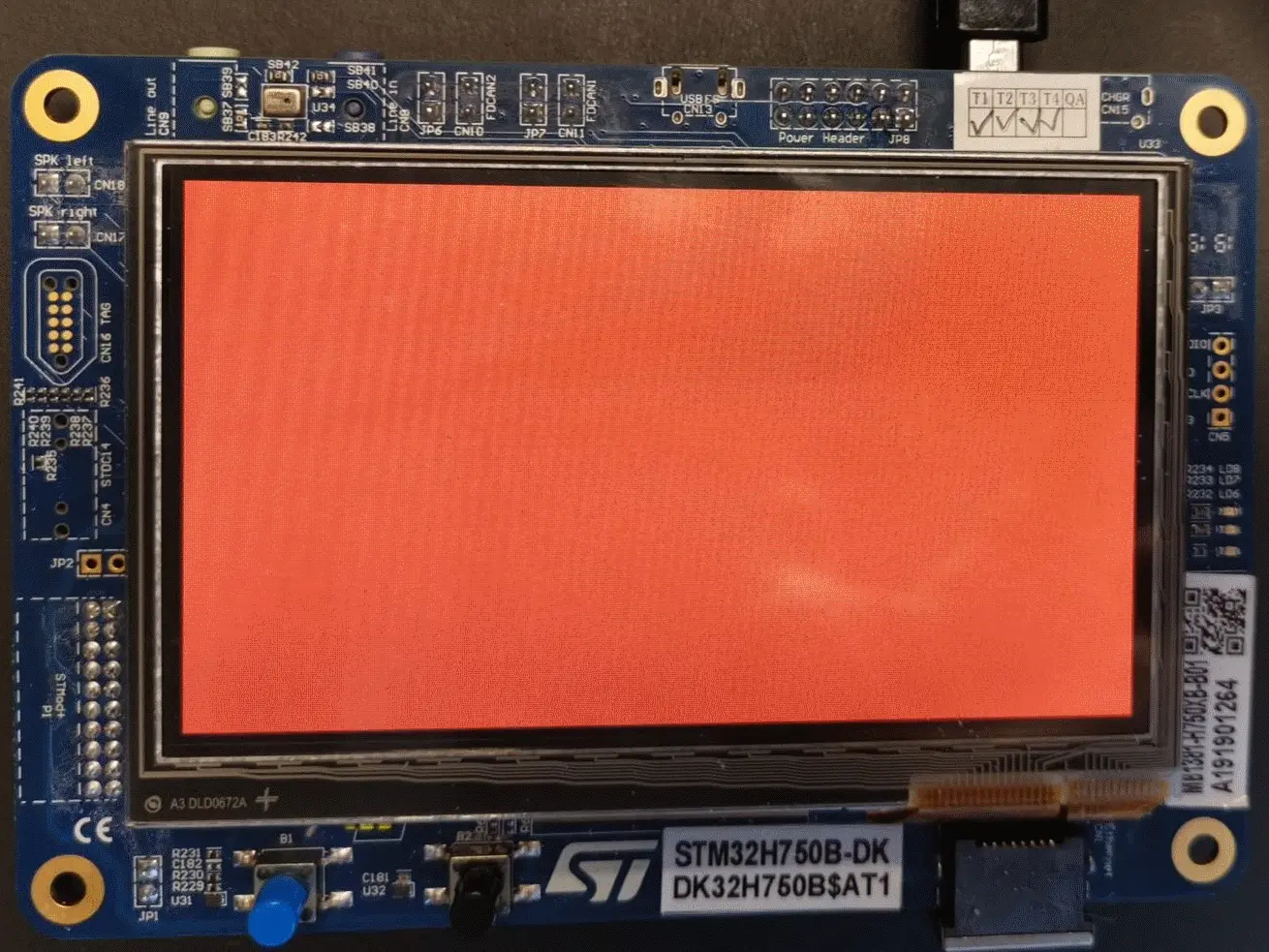

Framebuffer (or GRAM) of DC Charging pile Charging control unit...

What does a mechanical locking mechanism consist of

The mechanical locking mechanism of the charging head of the DC charging pile (also known as DC fast charge) refers to the safety and reliability of the connection between the charging cable and the electric vehicle (EV) or hybrid electric vehicle during charging. This mechanism is essential to ensure the safe and reliable operation of the charging process. The following is a detailed description of the key components of the mechanical locking mechanism:

Key Components

The charging gun head is designed with specific connector types (e.g., CCS-Combo, CHAdeMO, Tesla) that fit into the vehicle's port. Each connector type will have its own locking mechanism tailored for its design.

Many mechanical locking systems feature a pin or bolt that engages with a receptor on the vehicle when the connector is inserted. This pin is usually spring-loaded, ensuring it automatically engages when the connection is made.

In some designs, the locking mechanism may involve a sliding or rotating component that must be moved into place to secure the connector. For example, a rotary lock may require a quarter turn after insertion to lock the connector in place.

Springs can be employed to automatically engage or disengage the locking mechanism, ensuring that the connector is firmly locked during charging and easily released when the charge is complete.

The gun head incorporates a release mechanism that might be a button or lever. This release allows the locking pin to retract or the rotary mechanism to disengage so that the connector can be safely removed after charging.

Many locking mechanisms are designed with safety features that prevent disengagement while charging is in progress. For example, the release mechanism may only be operable when the charger is not actively supplying power, mitigating risks of electric shock or connector damage.

Some systems incorporate visual indicators (like LEDs) that show the status of the locking mechanism or charging process, providing information to the user about whether the connection is secure.

Working Principle

Insertion:

When the charging gun head is inserted into the vehicle's charging port, the connector design ensures proper alignment and makes contact with the charging pins inside the port.

Lock Engagement:

As the connector becomes fully inserted, the locking mechanism (such as a sliding pin) engages automatically or is manually activated, securing the connection.

Charging Process:

The charging process commences, during which the mechanical lock maintains the connection, ensuring that the electrical contacts remain secure and that there is no disconnection due to motion or vibration.

Disengagement:

Once charging is complete, the user presses the release button or moves the lever. This action disengages the locking mechanism, allowing for safe removal of the charging gun head from the vehicle.

Importance of Mechanical Locking

Safety: Ensures that the connection stays intact during charging, minimizing risks of electric shock or equipment damage.

Reliability: Prevents accidental disconnections that could interrupt charging.

User Experience: Makes it easy for users to connect and disconnect the charger without unnecessary complications.

Conclusion

The mechanical locking mechanism in DC charging pile charging gun heads is an essential feature that enhances the usability, safety, and reliability of electric vehicle charging systems. By providing a secure connection during charging, it plays a vital role in the growing EV infrastructure. As the market continues to evolve, advancements in this technology will further improve the efficiency and user-friendliness of charging systems.

DC CHARGING PIlE SERIES

DC charging pile is an efficient charging facility for electric vehicles, which uses direct current (DC) to directly charge the vehicle battery, significantly reducing the charging time. Compared with traditional AC charging piles, DC charging piles are able to provide higher power output and can usually charge an EV to 80% of its capacity in 30 minutes, providing users with a convenient charging experience.

Extended reading

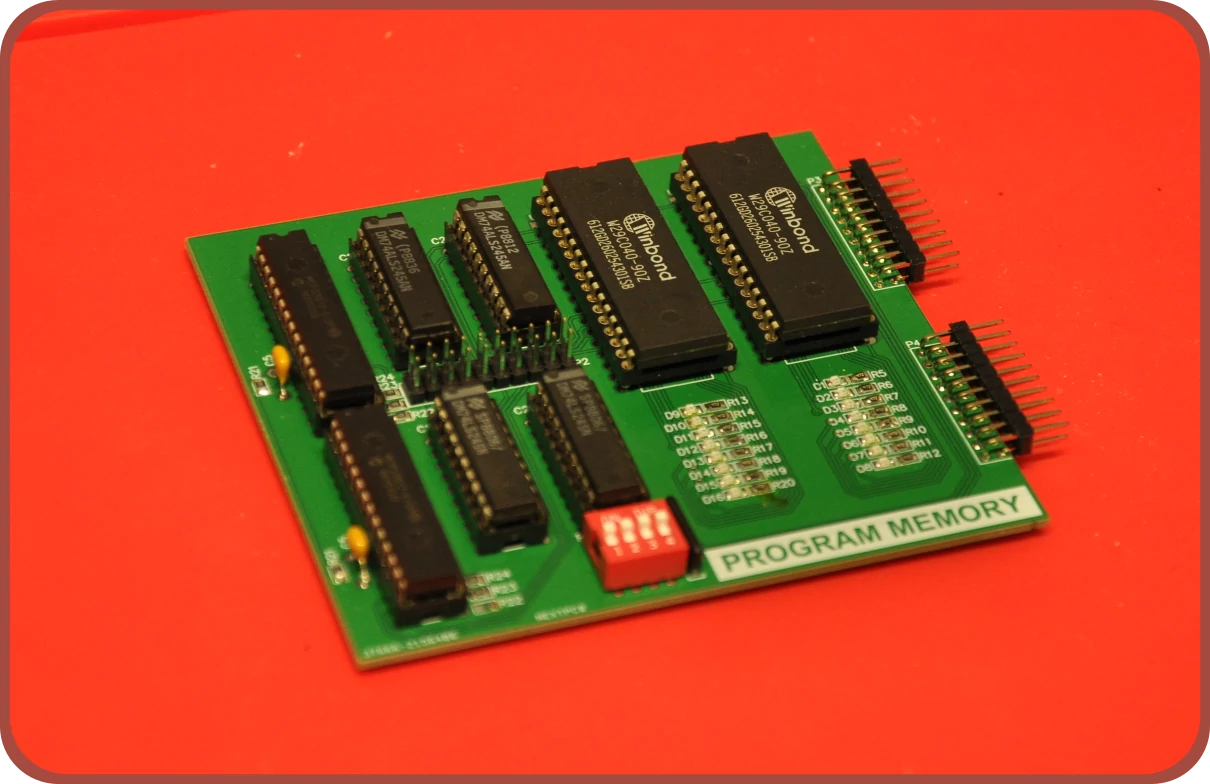

Program memory for DC charging pile microcontrollers: Solid building blocks for firmware

Program memory for DC charging pile microcontrollers: Solid building blocks...

Power and Communication Interface of DC charging pile reader

Power and Communication Interface of DC charging pile reader Main...

What is the effect of sheet molding plastic on the shell of DC charging pile?

What is the effect of sheet molding plastic on the...

Dc charging pile microcontroller central processing unit: the core of intelligent control

Dc charging pile microcontroller central processing unit: the core of...

THE ESSC Brand promise

Global supply

Our products sell well all over the world, covering many countries and regions, through the global logistics network, to provide customers with convenient purchasing experience.

Rigorous quality

We adhere to the highest quality control standards to ensure every product meets industry regulations and customer expectations, earning trust through consistent excellence.

Excellent service

With a customer-centric approach, we provide prompt responses, professional support, and personalized services, aiming to deliver the best user experience and long-term value.