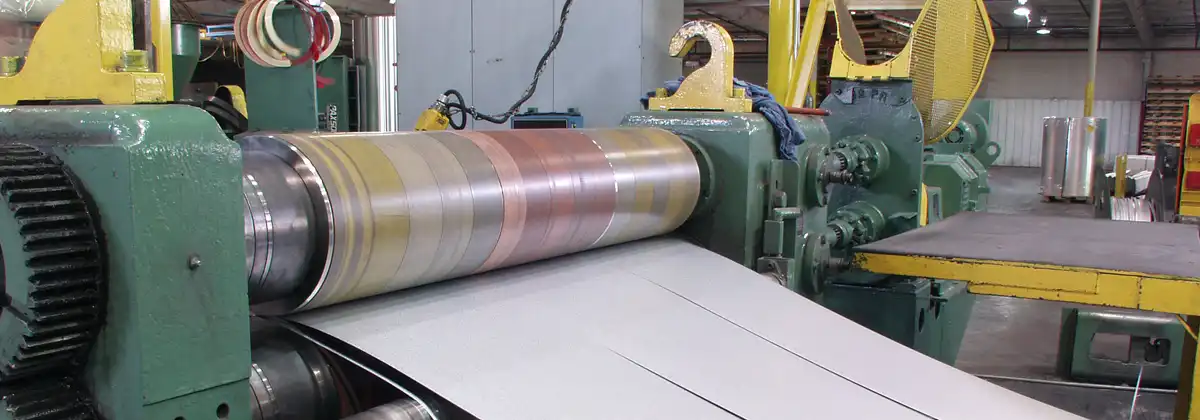

Production process 4-Cutting and slitting Uninterruptible Power Supply (UPS) is...

What are the pre-processing steps for the battery module before and after the capacitance test?

The pre-treatment of battery modules before and after capacitance testing is a key step to ensure battery performance and safety. Here's a breakdown of these steps:

main content

Charge to preset State of Charge (SOC)

Before the capacitance detection, the treated single battery needs to be charged so that the state of charge (SOC) of the battery reaches the first preset value, usually the state of full charge (100% SOC).

Static and pressure drop monitoring

Cells that reach the first preset value stand for the first preset time (for example, 48-72 hours), and monitor the voltage drop of each cell to screen out cells whose voltage drop is greater than the first preset voltage drop.

SOC Adjustment

Adjust the SOC of each cell after screening to the second preset, where the second preset is less than the first preset (for example, adjusted to 50% SOC).

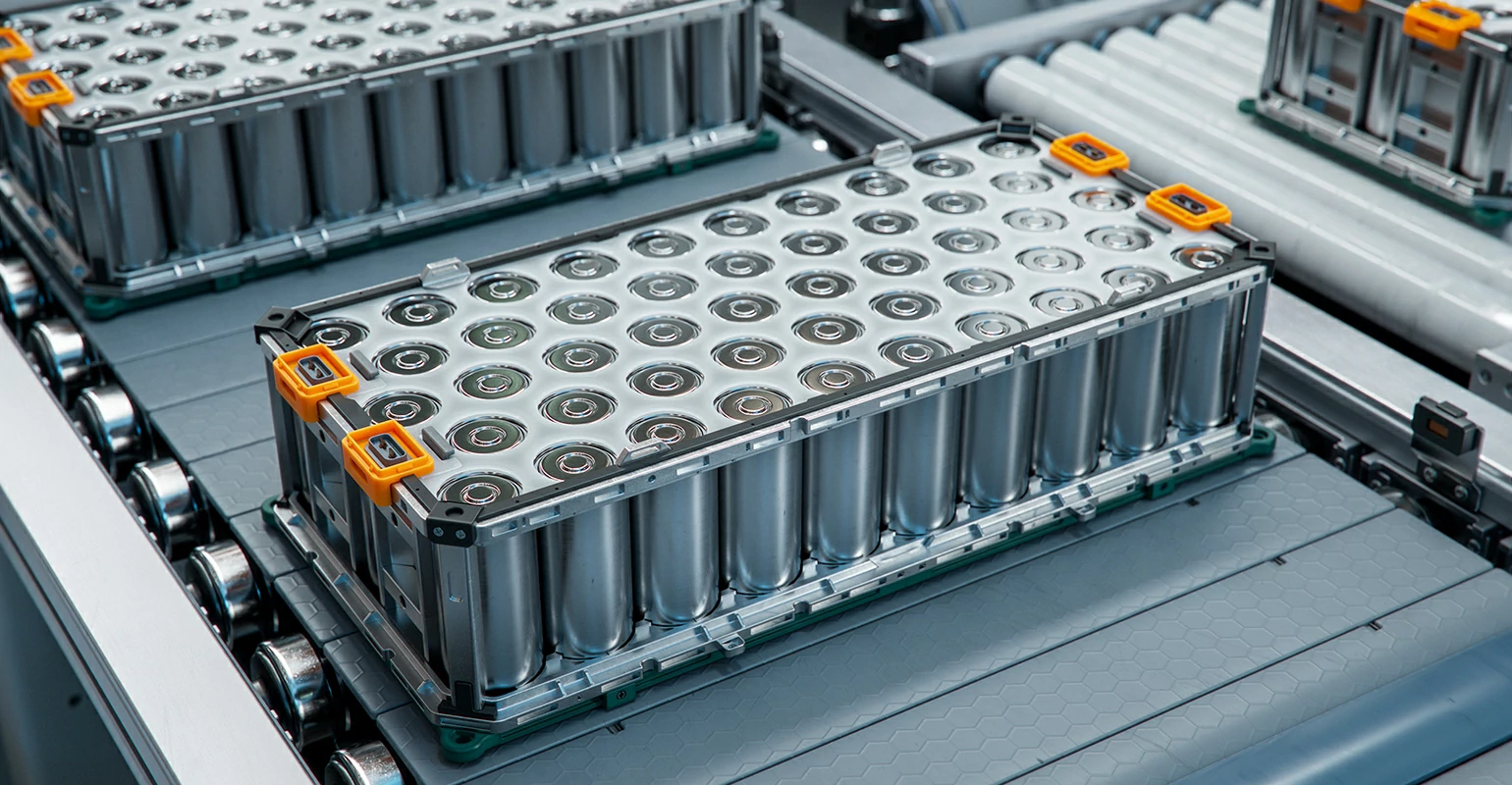

Battery module assembly

The adjusted individual battery is assembled into a battery module, and the battery module is charged so that its SOC reaches a third preset value, usually greater than the second preset value (for example, charged again to 100% SOC).

Secondary standing and pressure drop judgment

Stand the battery module at a preset temperature (e.g. 20-25°C) for a second preset time (e.g. 48-72 hours), and judge whether the battery module is qualified by judging the voltage drop of the battery module. If the voltage drop of the battery module is greater than the second preset voltage drop, the battery module is unqualified.

Cleaning

Before the capacitance test, the battery needs to be cleaned to remove surface oil and impurities. Before cleaning, it is necessary to check whether the roller, belt and other parts of the cleaning machine are clean, so as not to pollute the battery.

Pretreatment

The battery is placed in a chemical tank for pretreatment. Pretreatment is mainly to remove oxides and other impure substances inside the battery, so that the battery can reach a clean state more quickly during subsequent commissioning. Pretreatment can be performed using acidic or alkaline solutions.

Plasma pretreatment

Plasma cleaning and activation of the carrier film before coating the paste ensure stable battery performance. Plasma technology is also suitable for surface activation/cleaning of battery modules to ensure optimal surface characteristics and reliable bonding or packaging.

CONCLUSION

The above pretreatment steps can ensure the performance and safety of the battery module before and after the capacitance detection, and improve the consistency and reliability of the battery.

UPS BATTERY SERIES

UPS (Uninterruptible Power Supply) batteries are an important component of power supply systems designed to provide stable power support for electronic devices.

Extended reading

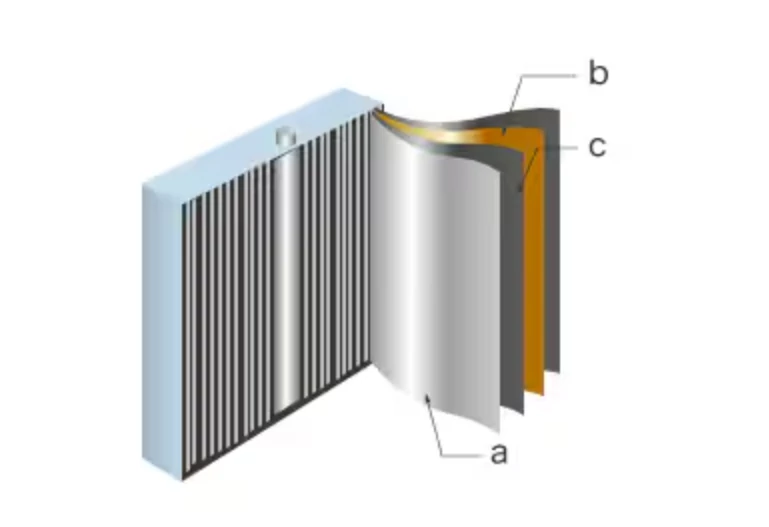

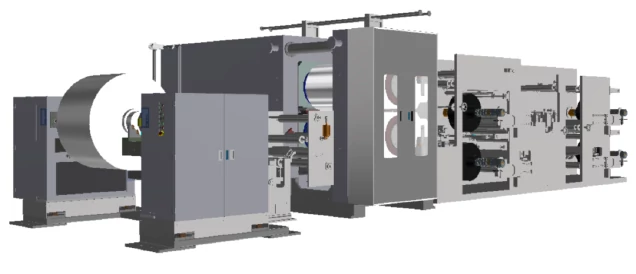

Production Process 2- Coating

Production Process 2- Coating Uninterruptible Power Supply (UPS) is an...

Production process 10- Formation

Production process 10- Formation In the UPS (uninterruptible power supply)...

Production process 8- baking

Production process 8- baking In the UPS (uninterruptible power supply)...

Production process 3- roll pressing

Production process 3- roll pressing Uninterruptible Power Supply (UPS) as...

What are the pre-processing steps for the battery module before and after the capacitance test?

What are the pre-processing steps for the battery module before...

THE ESSC Brand promise

Global supply

Our products sell well all over the world, covering many countries and regions, through the global logistics network, to provide customers with convenient purchasing experience.

Rigorous quality

We adhere to the highest quality control standards to ensure every product meets industry regulations and customer expectations, earning trust through consistent excellence.

Excellent service

With a customer-centric approach, we provide prompt responses, professional support, and personalized services, aiming to deliver the best user experience and long-term value.