Introduction to Residual Current Device of DC charging pile Leakage...

What are communication contacts made of?

Communication Contacts, also known as communication connectors, consist of the following main components:

Main component

The outer casing of the connector, its functions include structural reinforcement, defining the mating frame of male and female connectors, positioning the connector PCB, and sharing external force mechanical protection. In terms of electricity, the shell also has functions such as EMI shielding and ESD grounding.

The connector installed on the printed circuit board is called the header, which is also known as the base or seat. The main difference between the header and the housing is that the header is always mounted with the circuit pins, while the housing is just an empty shell.

Including terminals and pins, they are the core parts of the connector that complete the electrical connection function, also known as contact terminals. Generally, they consist of male and female contact pieces that form a contact pair, completing the electrical connection through the mating of male and female contacts.

Also known as the base or mounting board, it is the main structural component of the entire connector, determining the appearance size of the connector and the positioning of various parts. The material of the insulator is generally plastic, and its main functions include electrical insulation between terminals, fixing the geometric position of the terminals, providing mechanical protection and support for the terminals, and isolating the terminals from the application environment to reduce sensitivity to corrosion.

Accessories

Accessories are divided into structural accessories and installation accessories, such as card retainers, positioning pins, guide pins, connecting rings, cable clamps, sealing rings, etc., used to assist in connection and fixation.

These components together form the communication connector, ensuring the transmission of electrical signals, the stability of connections, and mechanical and environmental protection.

DC CHARGING PIlE SERIES

DC charging pile is an efficient charging facility for electric vehicles, which uses direct current (DC) to directly charge the vehicle battery, significantly reducing the charging time. Compared with traditional AC charging piles, DC charging piles are able to provide higher power output and can usually charge an EV to 80% of its capacity in 30 minutes, providing users with a convenient charging experience.

Extended reading

Dc charging pile power switch chip start module

Dc charging pile power switch chip start module Main component...

Dc charging pile meter data processing and storage components

Dc charging pile meter data processing and storage components Main...

Contact Spring of Dc charging pile

Contact Spring of Dc charging pile Main component Concept: The...

Dc charging pile display chip timing controller

Dc charging pile display chip timing controller Main component Concept:...

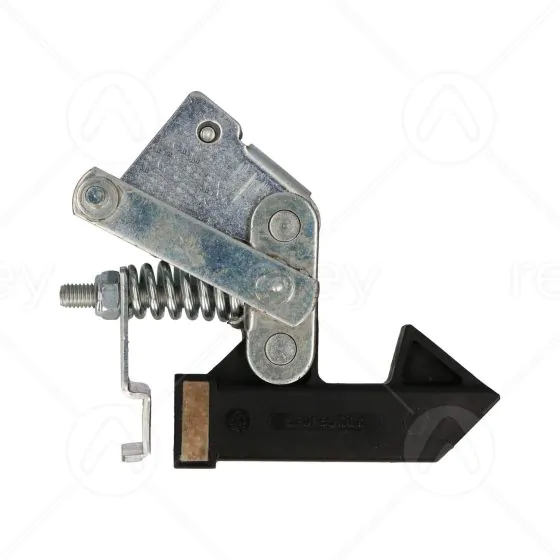

Release mechanism in mechanical locking device

Release mechanism in mechanical locking device In the design of...

THE ESSC Brand promise

Global supply

Our products sell well all over the world, covering many countries and regions, through the global logistics network, to provide customers with convenient purchasing experience.

Rigorous quality

We adhere to the highest quality control standards to ensure every product meets industry regulations and customer expectations, earning trust through consistent excellence.

Excellent service

With a customer-centric approach, we provide prompt responses, professional support, and personalized services, aiming to deliver the best user experience and long-term value.