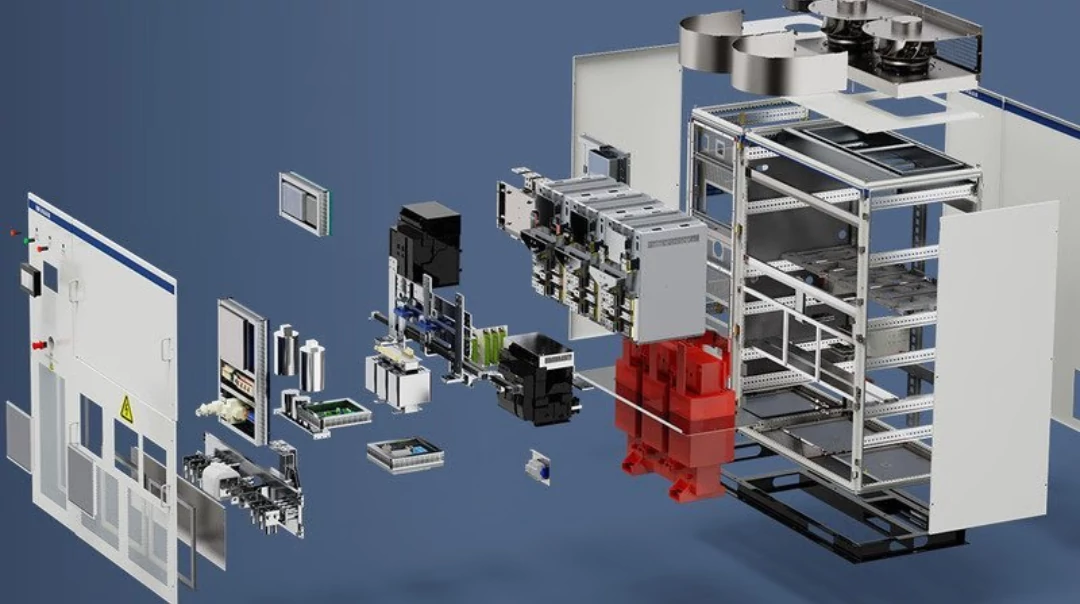

PCS Composition of PCS PCS, as the core component of...

Wet process process

Wet process is also known as phase separation method or heat-induced phase separation method, liquid hydrocarbon or some small molecular substances and polyolene grease mixed, heating and melting, forming a uniform mixture, and then cooling phase separation, pressing the diaphragm, and then heating the diaphragm to close to the melting point temperature, bi-directional stretching to make the molecular chain orientation, and finally holding a certain time, The porous membrane material can be prepared by eluating the residual solvent with volatile substances. According to whether the orientation is at the same time, the wet process can also be divided into wet bidirectional asynchronous stretching process and bidirectional synchronous stretching process.

The process flow of wet asynchronous stretching

1) Feeding: PE, pore-forming agent and other raw materials are pretreated and transported to the extrusion system according to the formula.

2) Flow casting: the pretreated raw material is melted and plasticised in the twin-screw extrusion system, and then the melt is extruded from the die head, and the melt is formed into a flow casting thick sheet containing pore-forming agent after flow casting.

3) Longitudinal stretching: longitudinally stretching the thick sheet.

4) Transverse stretching: transverse stretching of the thick sheet after longitudinal stretching to obtain the base film containing pore-forming agent.

5) Extraction: the basement membrane is extracted by solvent to form the basement membrane without pore-forming agent.

6) Setting: the base film without pore-forming agent is dried and set to obtain nano-microporous film.

7) Cutting: cutting the nanoporous membrane into finished film according to the customer's specifications.

The process flow of wet synchronous stretching technology is basically the same as that of asynchronous stretching technology, except that the stretching can be oriented in both horizontal and vertical directions at the same time, eliminating the process of longitudinal stretching alone and enhancing the uniformity of diaphragm thickness. However, the problem of synchronous stretching is that the vehicle speed is slow, and the second is that the adjustability is slightly poor, only the transverse stretch ratio is adjustable, and the longitudinal stretch ratio is fixed.

Application field of wet process

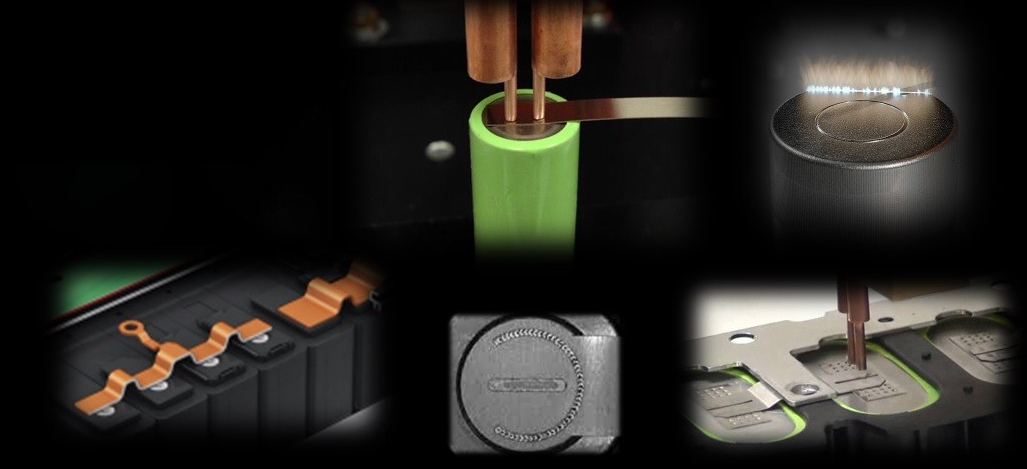

Battery manufacturing

In the synthesis of positive and negative battery materials, wet processes are used to make high-purity, high-performance compounds. Especially in the production of lithium batteries, the wet process is used to prepare metal salts and compounds, which is the key to improve the performance and life of the battery.

Metallurgical industry

Hydrometallurgy is a comprehensive process of treating metal ores through aqueous solutions. In such applications, wet processes are commonly used to extract valuable metals such as lithium, nickel, cobalt, etc. from ores. This method usually includes steps such as leaching, precipitation, and electrolysis.

Chemical and pharmaceutical

Wet process is widely used in the synthesis, refining and purification of chemical raw materials. In the pharmaceutical field, wet process can be used to obtain high purity pharmaceutical intermediates and active ingredients.

Environmental protection

Wet process is often used in environmental protection technology such as sewage treatment, waste gas purification and solid waste recycling. Wet treatment can effectively remove pollutants and reduce the pollution of air and water.

Advantages of wet process

Efficiency: Wet processes can be carried out at lower temperatures and pressures, saving energy and reducing equipment losses.

High product purity: Through solvent selection and control, the purity and consistency of the final product can be improved, especially in high fineness.

Resource and energy utilization: Wet processes are more environmentally friendly and economically efficient by recovering and reusing by-products from operations.

Challenges of wet process

Waste liquid treatment: The waste liquid generated in the process needs to be strictly treated to prevent environmental pollution. This process is not only tedious, but also increases operational costs.

Equipment corrosion: Chemicals in liquids can cause corrosion of production equipment, so material selection and protective measures are particularly critical.

Energy consumption control: Although the overall energy consumption of the wet process is low, the energy management of some specific processes is still a technical difficulty.

conclusion

Wet process has been widely used in many industrial fields due to its significant advantages of high efficiency, flexibility and adaptability. As technology advances, wet processes will continue to play an important role in improving processing efficiency, product quality, and environmental protection. At the same time, the environmental protection and technological challenges are also constantly promoting the development and application of new technologies to improve the economic efficiency and sustainability of the whole production process.

Home energy storage product series

A lithium battery pack for home energy storage systems, which is compatible with solar panels and the sun The inverter can work together with the power grid to power household appliances, and it can also be used as a For off grid systems.

Extended reading

Technical parameters of lithium iron phosphate battery pack

technical parameters of lithium iron phosphate battery pack Lithium iron...

Product testing of welding terminals

Product testing of welding terminals The quality of the soldered...

THE ESSC Brand promise

Global supply

Our products sell well all over the world, covering many countries and regions, through the global logistics network, to provide customers with convenient purchasing experience.

Rigorous quality

We adhere to the highest quality control standards to ensure every product meets industry regulations and customer expectations, earning trust through consistent excellence.

Excellent service

With a customer-centric approach, we provide prompt responses, professional support, and personalized services, aiming to deliver the best user experience and long-term value.