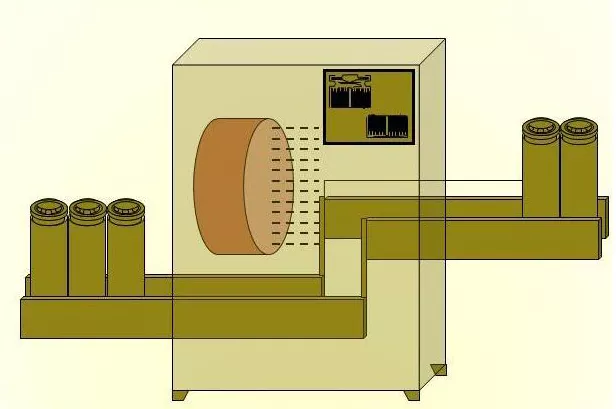

OCV measurement In the lithium battery production process, OCV (Open...

wash

The cleaning link in the lithium battery production process is crucial, which mainly involves the removal of impurities, pollutants and residues that may be attached to the surface of the battery during the manufacturing process to ensure the quality and performance of the battery. The following is a detailed description of the cleaning process:

Cleaning purpose

The purpose of the cleaning process is to improve the electrochemical performance of the battery, reduce internal resistance, extend the life of the battery, and ensure the safety and reliability of the battery.

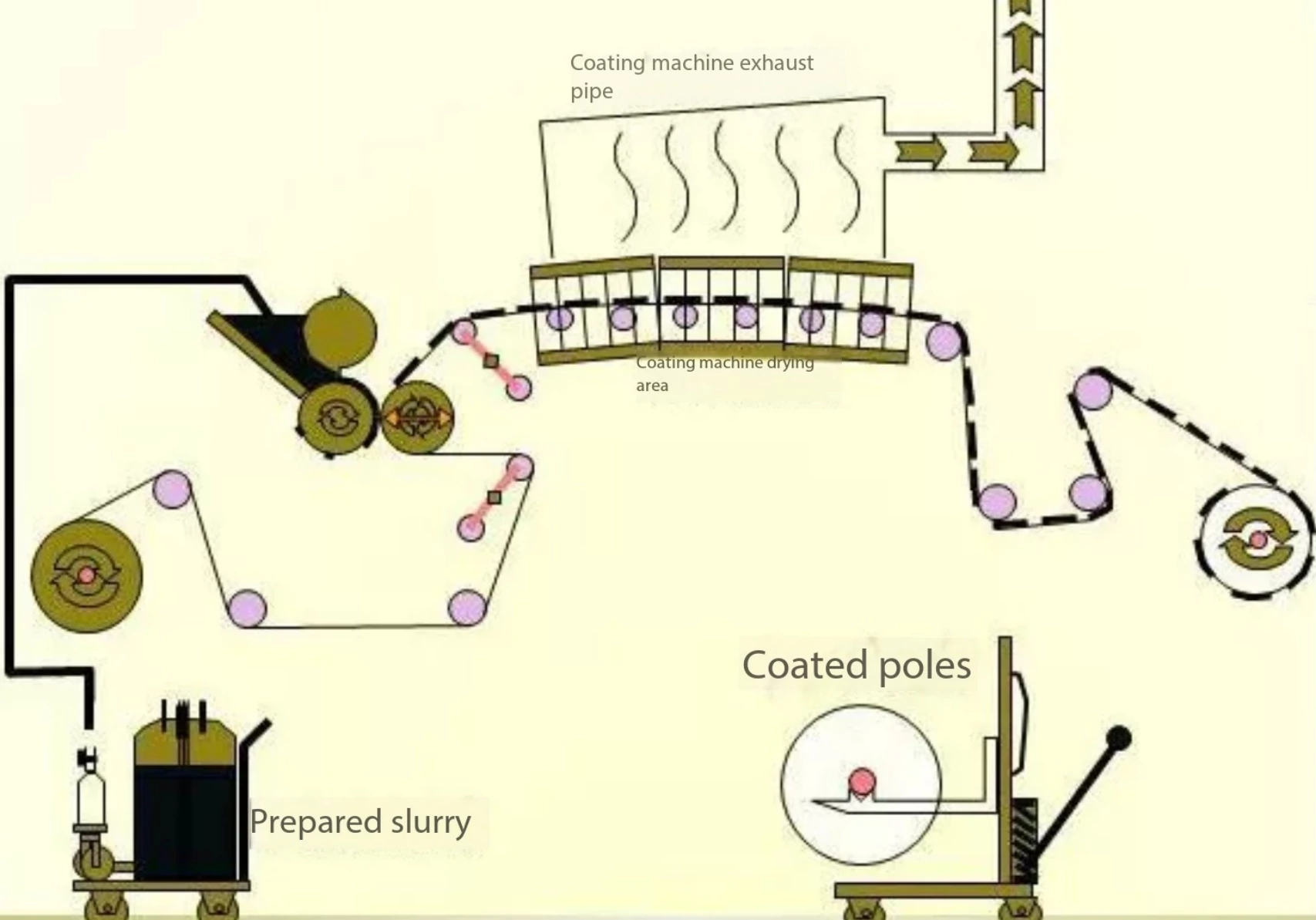

Cleaning process

The cleaning process of lithium batteries is generally divided into three steps: pre-treatment, main cleaning and post-treatment:

Pre-treatment: The appearance of the lithium battery is inspected to ensure that there is no obvious damage and surface defects. Then it is pre-cleaned, and the battery surface is cleaned with detergent to remove surface impurities and contaminants.

Main cleaning: According to different cleaning needs and process requirements, choose the appropriate cleaning method. The main cleaning methods include mechanical cleaning, water washing, ultrasonic cleaning, etc.

Post-treatment: After the main cleaning, the post-treatment process, including rinsing, dehydration and drying. Rinsing is to remove the residue of the cleaning agent and the water on the surface, dehydration is to remove the cleaning solution and water by centrifuging or blowing, and drying is to thoroughly dry the battery surface.

Cleaning method

Sodium nitrite solution spray cleaning: Use sodium nitrite solution to spray clean lithium battery structural parts. The key points of operation include controlling the spray pressure and spray time to ensure that the solution can fully cover the surface of the structural part.

Deionized water spray cleaning: After cleaning with sodium nitrite solution, spray cleaning with deionized water again to remove residual cleaning solution.

Air gun dry: Compressed air is used to dry the cleaned lithium battery to remove surface moisture.

Brush anti-rust oil: After blowing dry, brush anti-rust oil on the battery surface to prevent rust on the battery surface.

Cleaning technique

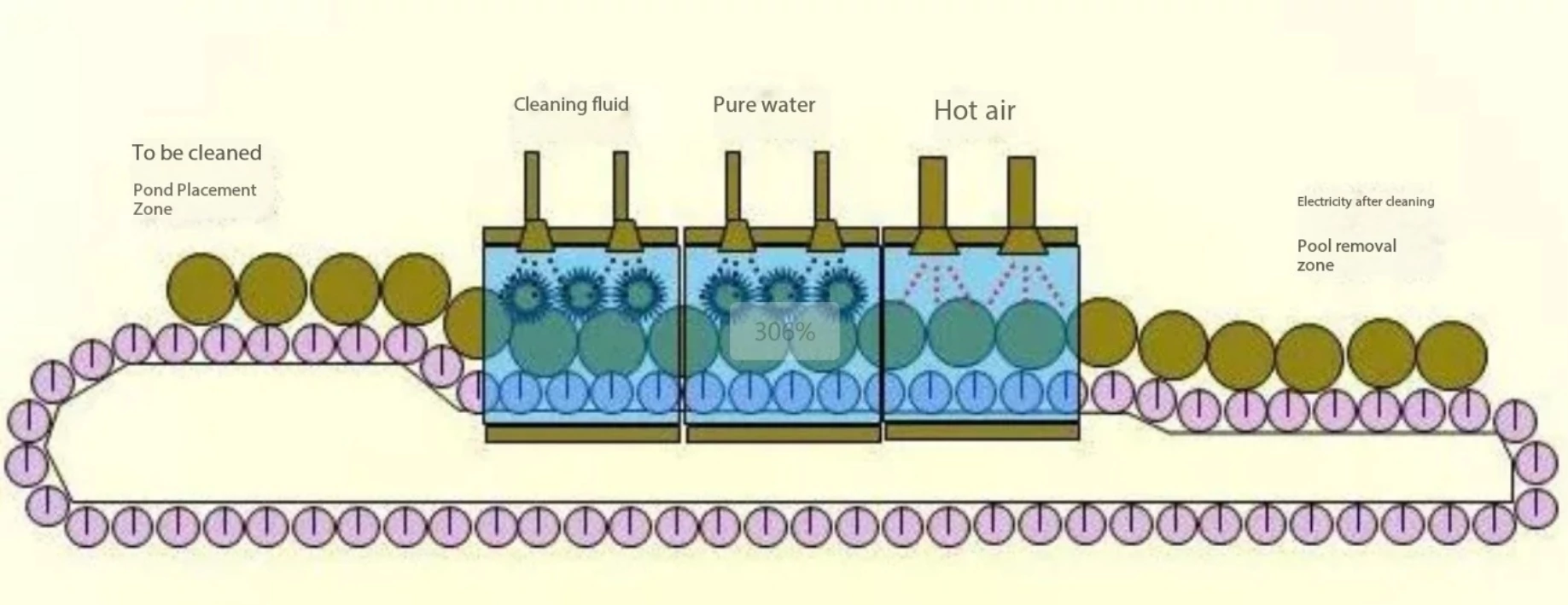

Laser cleaning technology: Laser cleaning has become the main means of battery surface treatment, and is widely used in pole plate manufacturing, cell production and battery assembly. Laser cleaning technology can improve cleaning efficiency, save resources, establish real-time monitoring of cleaning process data and quantitative evaluation of cleaning results, and improve the consistency of electrode batch production.

Plasma cleaning: The application of plasma cleaning in the lithium battery industry can greatly improve the level of battery manufacturing process. Plasma cleaning is a dry cleaning that mainly relies on the "activation" of active ions in plasma to remove stains on the surface of objects.

Cleaning device and method

The cleaning device comprises a cleaning chamber, a rolling transmission mechanism and a cleaning mechanism. The cleaning method includes driving the lithium battery to move in the cleaning chamber through the rolling transmission mechanism, and cleaning the surrounding side wall and the bottom wall of the lithium battery through the cleaning mechanism.

CONCLUSION

Through the above cleaning processes and methods, the cleaning process in the production process of lithium batteries can ensure the cleanliness and performance of the battery, and provide guarantee for the subsequent battery packaging and use.

EPS BATTERY SERIES

The centralized power supply for fire emergency lighting is a kind of backup power supply equipment, which provides power guarantee for emergency lighting equipment to ensure that the on-site lighting equipment can operate normally in emergency situations such as fire. Provide a long-term backup power supply to meet the needs of the emergency lighting system.

Extended reading

Storage at normal temperature

Storage at normal temperature Lithium batteries need to follow specific...

THE ESSC Brand promise

Global supply

Our products sell well all over the world, covering many countries and regions, through the global logistics network, to provide customers with convenient purchasing experience.

Rigorous quality

We adhere to the highest quality control standards to ensure every product meets industry regulations and customer expectations, earning trust through consistent excellence.

Excellent service

With a customer-centric approach, we provide prompt responses, professional support, and personalized services, aiming to deliver the best user experience and long-term value.