UPS production process introduction As an important part of modern...

UPS production process introduction

As an important part of modern power system, uninterruptible power supply (UPS) is widely used in data center, industrial automation, medical equipment and all kinds of high-precision electronic equipment. With the continuous growth of market demand, the production process of UPS is also constantly improving. In this article, we will detail the main production processes of UPS to help you better understand its manufacturing process and technical features.

Main production process

This stage involves selecting and preparing suitable battery materials, such as cathodes, anodes and electrolytes. The quality and formulation of these materials directly affect the energy storage capacity and service life of the UPS.

In this stage, the selected material is evenly coated on the metal foil to form the electrode. This step is crucial for the battery's electrical performance.

The coated electrode sheet is rolled to improve its shape and structure and enhance the mechanical strength of the battery.

Cut and slitting as required to facilitate subsequent winding and assembly.

The positive and negative lugs are welded together to form the basic unit of the battery. Winding: Put the welded pole lug into the winding machine and roll it into a cylinder shape according to the specified spacing. Packaging: The wound battery unit is placed in a vacuum environment, injected with electrolyte, and packaged to form the final battery unit.

Put the welded pole lug into the winding machine and roll it into a cylinder shape according to the specified spacing.

The wound battery unit is placed in a vacuum environment, injected with electrolyte, and packaged to form the final battery unit.

The packaged battery unit is baked in a vacuum oven to remove internal moisture and prevent short circuit of the battery.

After baking, the electrolyte is injected again to complete the activation process of the battery.

After the battery is injected into the electrolyte, the formation process is carried out to make the chemical substances inside the battery fully react to form a stable structure.

The formed battery unit is formed to become the final UPS battery module.

Capacity test the formed battery module to ensure that its performance meets the standard requirements of the UPS.

CONCLUSION

UPS's production process is a comprehensive system engineering, at every stage, manufacturers adhere to high standards and strict requirements to ensure product quality and reliability. With the continuous progress of technology and changes in market demand, the production process of UPS will continue to be optimized to provide users with more efficient and safer uninterruptible power solutions.

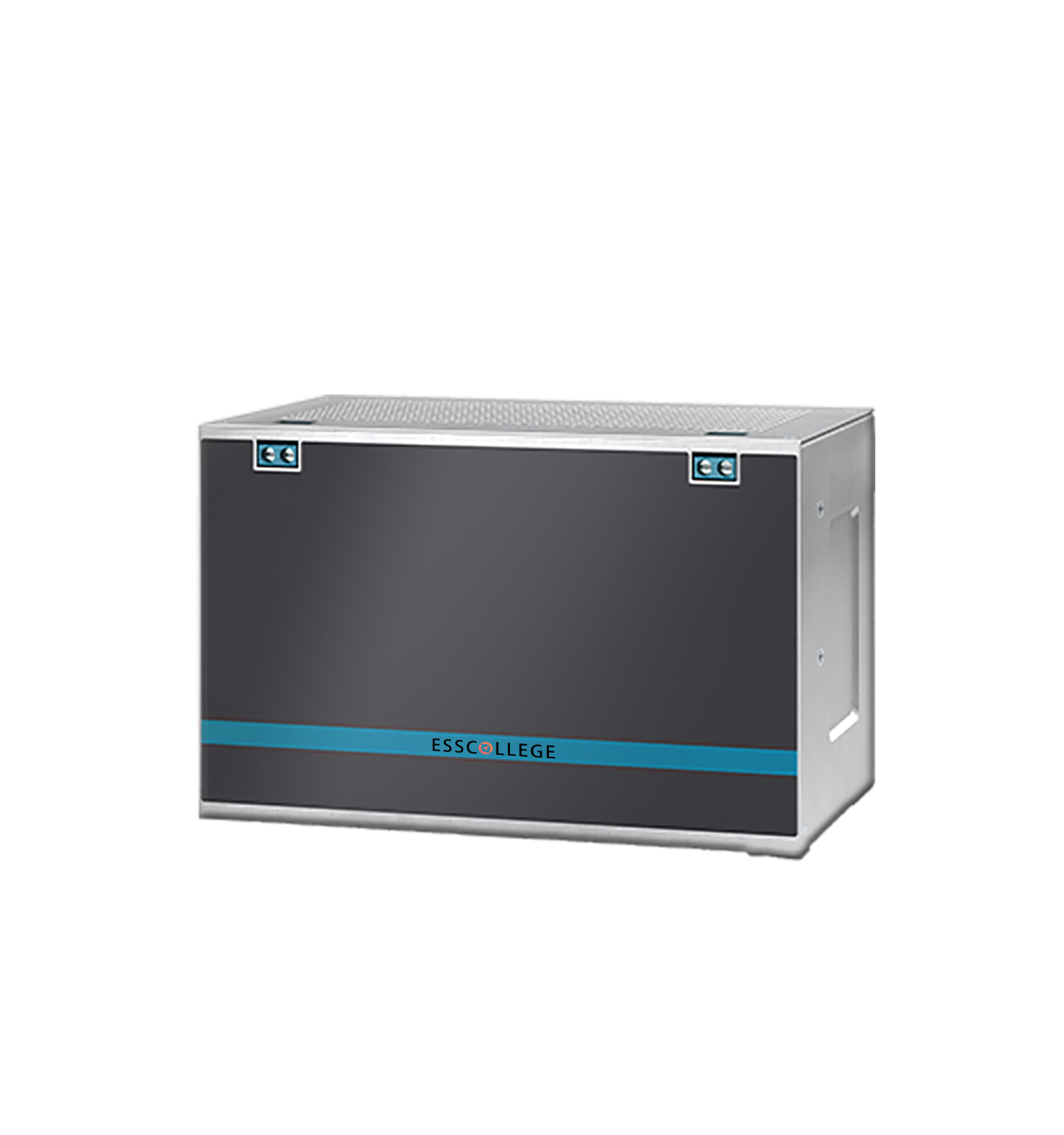

UPS BATTERY SERIES

UPS (Uninterruptible Power Supply) batteries are an important component of power supply systems designed to provide stable power support for electronic devices.

Extended reading

UPS Application Scenarios

UPS application Scenarios Uninterruptible power supply (UPS) is an effective...

THE ESSC Brand promise

Global supply

Our products sell well all over the world, covering many countries and regions, through the global logistics network, to provide customers with convenient purchasing experience.

Rigorous quality

We adhere to the highest quality control standards to ensure every product meets industry regulations and customer expectations, earning trust through consistent excellence.

Excellent service

With a customer-centric approach, we provide prompt responses, professional support, and personalized services, aiming to deliver the best user experience and long-term value.