Product testing Product testing is a key link to ensure...

Thermal management system for the battery pack

The Thermal Management System (TMS) plays a crucial role in ensuring the safety, efficiency and long life of the battery pack. Batteries generate heat during charging and discharging. If the heat is not effectively dispersed or properly controlled, it may lead to overheating of the battery and even safety accidents (such as thermal runaway, fire or explosion). Therefore, the goal of the thermal management system for the battery pack is to maintain the battery pack in a safe, stable and efficient temperature range.

Thermal management system for the battery pack

The main roles of a thermal management system include:

Maintain the battery in the optimal temperature range: Ensure that the battery is operating at the right temperature to improve the performance and life of the battery.

Prevent overheating: Avoid the battery due to high temperature and thermal runaway, resulting in battery damage or safety accidents.

Improve the charging and discharging efficiency: proper temperature control can improve the charging and discharging efficiency of the battery and reduce energy loss.

Extend battery life: through reasonable temperature control, reduce the impact of temperature fluctuations on the battery, so as to extend the service life of the battery.

The thermal management system includes

Temperature sensor

Function: The temperature sensor monitors the temperature change in the battery pack in real time. Through the data collected by the sensor, the thermal management system can judge the overall temperature condition of the battery pack and take corresponding control measures as needed. Location: It is common to install multiple temperature sensors at key locations of the cell, cell module, and battery pack, including the cell surface, internal battery connection points, etc., to ensure precise monitoring.

Thermal conductive material

Function: Thermal conductive materials are used to conduct heat between the cell and the thermal management system. They efficiently conduct heat from the cell cells to the heat sink or cooling medium for rapid discharge.

Common materials: Common thermal conductive materials are thermal conductive glue, thermal conductive gasket, etc., which usually have high thermal conductivity and appropriate flexibility, and can be in close contact with the battery monomer and conduct heat.

Heat dissipation device

Function: The heat sink is responsible for removing excess heat from the battery pack and dissipating it to the surrounding environment.

Common ways of heat dissipation:

Passive heat dissipation: The dissipation of heat into the surrounding air, primarily through natural convection and radiation. This method has simple structure and low cost, but relatively low heat dissipation efficiency, and is suitable for low-power battery packs.

Active heat dissipation: acceleration of heat transfer and dissipation by means of fans, liquid cooling or gas cooling. This method is more efficient and suitable for high power battery packs.

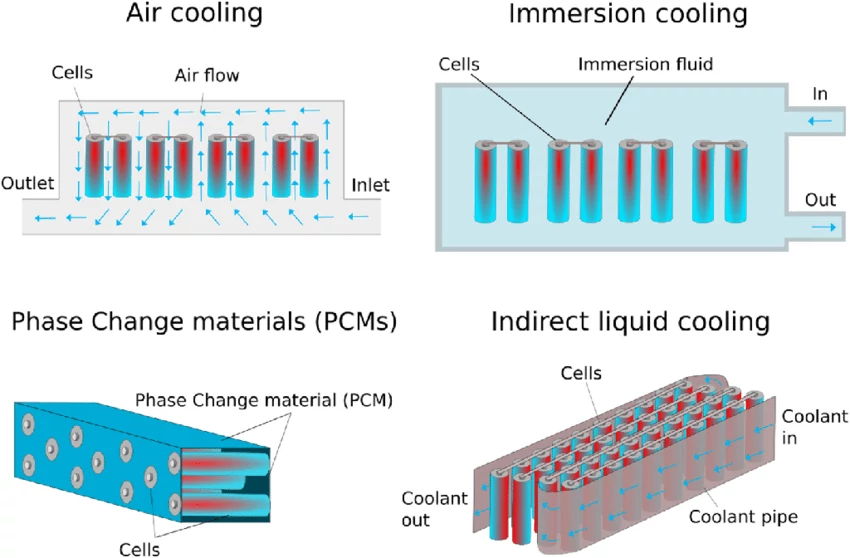

Air cooling system

Function: The air cooling system directs air to the surface of the battery pack through a fan or blower to enhance the conduction and dissipation of heat.

How it works: Air-cooled systems use air flow to speed up heat exchange and take away the heat generated by the battery. Air-cooled systems are simple in construction and low in cost, but the heat dissipation effect may be limited at high loads or ambient temperatures.

Liquid cooling system

Function: The liquid cooling system uses liquid as the cooling medium to transfer heat from the battery pack to the cooling device through the piping system, and then take the heat away.

Principle: Liquid cooling systems usually include pumps, coolants, heat exchangers, and pipes. The pump pushes the coolant to circulate, and the heat exchanger transfers the heat in the coolant to the external environment.

Phase change material (PCM)

Function: Phase change material can absorb heat when the temperature rises, and transform into liquid, thus slowing down the temperature rise; When the temperature drops, they release heat and revert to a solid state.

Application: Phase change materials can be used to play a thermal buffer role in the battery pack to help the battery pack balance temperature fluctuations, especially suitable for the scene of large environmental temperature changes.

Thermal management and control system

Function: The thermal management control system is responsible for automatically adjusting the working state of the cooling system according to the data of the temperature sensor. For example, controlling the speed of the fan, the flow rate of the pump, the temperature control of the liquid cooling system, etc.

How it works: By integrating control algorithms and sensor data, the thermal management system is able to monitor the temperature of the battery pack in real time, optimizing cooling effects and preventing overheating, while also reducing energy loss and system consumption.

low-speed car batteries

Low-speed vehicle battery is a kind of battery designed for low-speed electric vehicles, which has the characteristics of clean, environmental protection, high efficiency and economy, and is widely used in electric golf carts, low-speed electric vehicles (LSV), mobile vendors, campus transportation, cargo trucks and so on

Extended reading

Product packaging and delivery

Product packaging and delivery The packaging and delivery of battery...

Product information expansion

Product information expansion Understanding low-speed vehicle battery product information is...

Product composition

Low-speed lithium battery product composition Understanding the product composition of...

THE ESSC Brand promise

Global supply

Our products sell well all over the world, covering many countries and regions, through the global logistics network, to provide customers with convenient purchasing experience.

Rigorous quality

We adhere to the highest quality control standards to ensure every product meets industry regulations and customer expectations, earning trust through consistent excellence.

Excellent service

With a customer-centric approach, we provide prompt responses, professional support, and personalized services, aiming to deliver the best user experience and long-term value.