Contact Spring of Dc charging pile Main component Concept: The...

The thermal management and regulation function of DC charging pile is introduced

The thermal management and regulation function of the DC charging pile power management chip is the key technology to ensure the stable operation and prolong the service life of the charging pile. The following is a detailed discussion of these two functions:

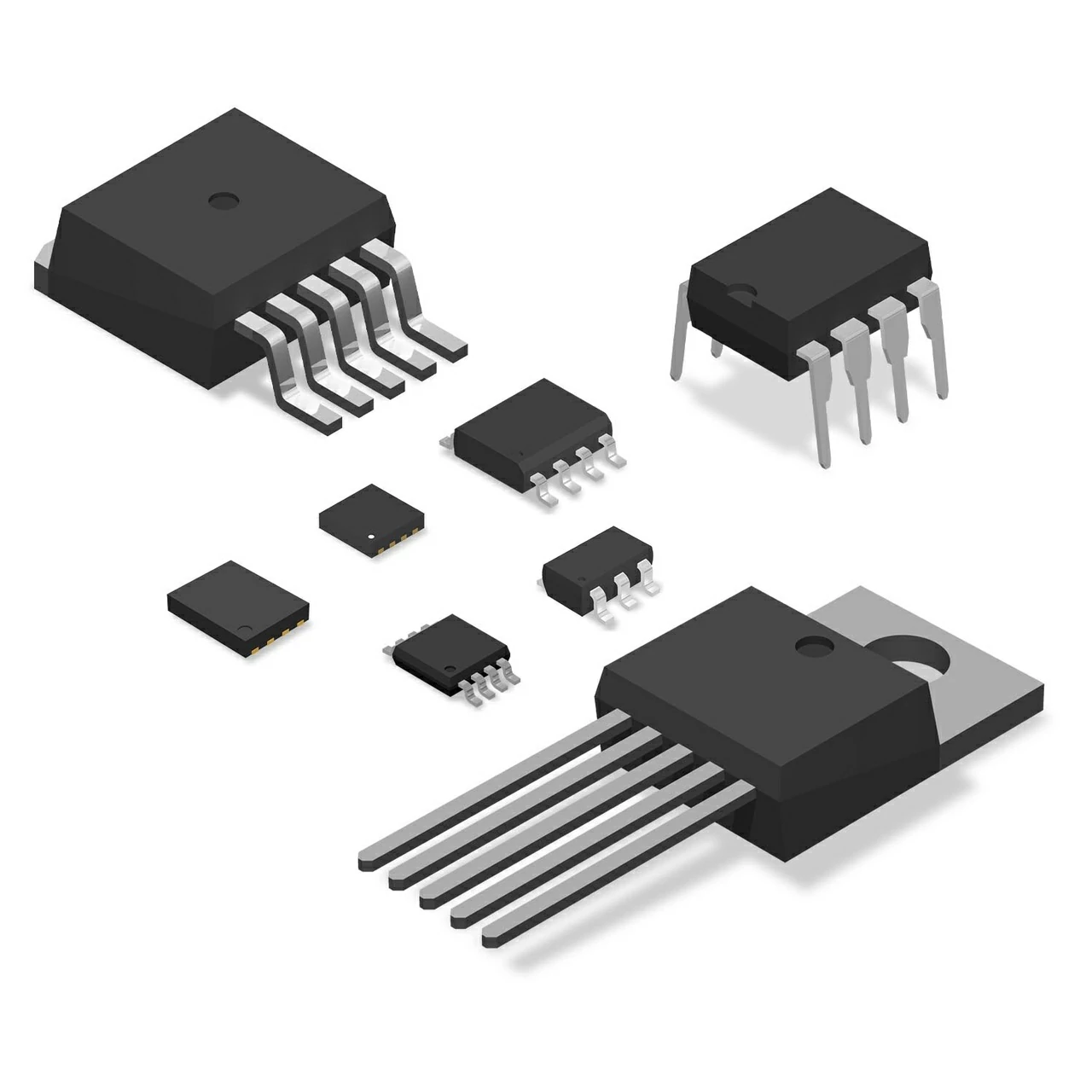

Main component

Thermal management

1. Application of thermal conductive materials: Thermal management of power management chips often uses materials such as thermal conductive gels, thermal interface phase change materials and insulating thermal conductive sheets. Thermal gel has high fluidity and high filling performance, suitable for automated dispensing process, can fill fine voids and provide low thermal resistance, thermal conductivity between 2.0~8.0 W/m·K. Thermal interface phase change materials soften and fully fill microscopic voids at specific temperatures, optimize thermal contact properties, and have extremely low thermal resistance for high power density applications. The insulating thermal conductive sheet is reinforced with glass fiber cloth, which has thermal conductivity, high pressure resistance and puncture resistance. The compressive strength can reach more than 10kV, and the thermal conductivity is 1.0~ 1.6W /m·K.

2. Liquid cooling technology: liquid cooling cycle technology is used for the thermal management of DC charging piles, and the temperature of charging piles can be effectively reduced through the liquid cooling system to improve charging efficiency and safety. The liquid cooling technology absorbs heat through the coolant and circulates it to the radiator, which is cooled by the fan and then circulates again to achieve efficient heat exchange.

3. Heat dissipation structure patent: Wasion Information Technology Co., Ltd. applied for the patent "a heat dissipation structure and heat dissipation system for DC charging pile" involving the field of electric vehicle charging technology, through the heat dissipation structure of the host to carry out linkage heat dissipation of the charging gun, reduce the heat dissipation operation cost of the charging pile to the charging gun, and improve the heat dissipation effect of the charging gun.

Adjustment function

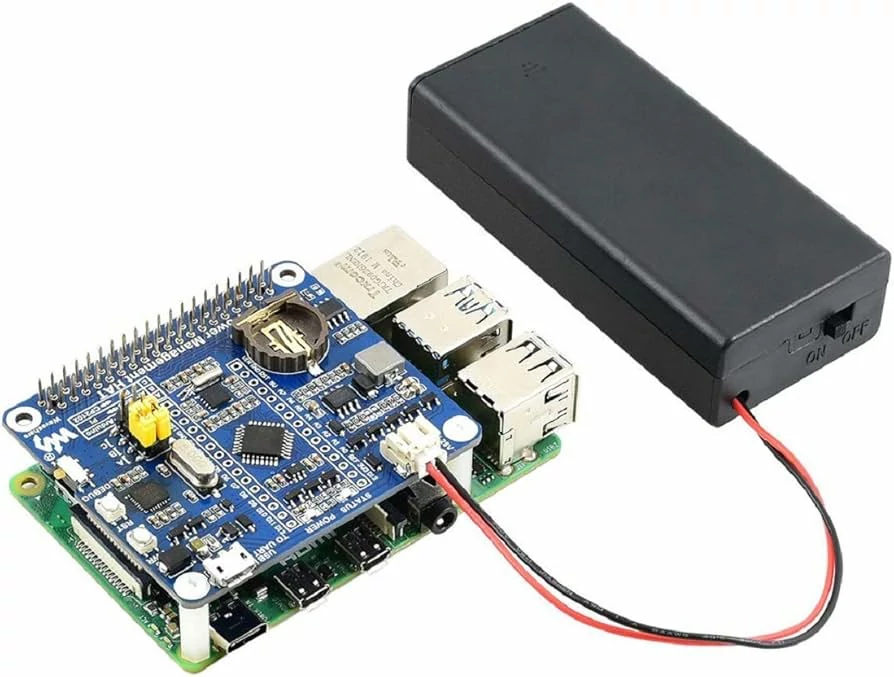

1. Power management and charge control: The power management chip has high-speed computing capability to meet the system's accurate power management and charge control needs. The chip has a variety of working modes to achieve flexible charging pile operation control. By changing the output power by adjusting the current, divide the power Pref of the charging pile by the voltage Ud to get the control output current of the charging pile: Ictrl = Pref/Ud.

2. Optimization control strategy: Considering the optimization control strategy of charging piles with multiple charging modes, the charging process can be optimized by adjusting current and voltage according to the characteristics and needs of charging piles to improve charging efficiency.

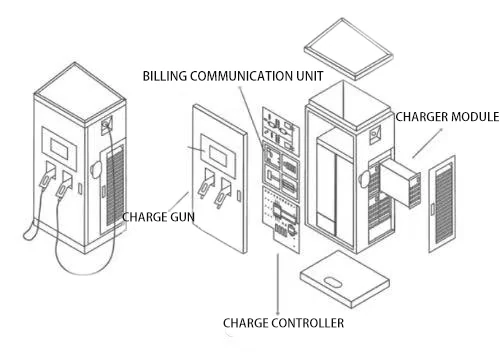

3. Control board principle: In the DC charging pile control board, the main control chip is responsible for the command processing and data management of the entire control board, the power management module is responsible for the power supply, protection and management of the DC charging pile, the communication module is responsible for the communication between the control board and the charging pile, and the charging control module is responsible for controlling the charging process.

Sum up

In summary, the thermal management and regulation function of the DC charging pile power management chip ensures the stable operation and efficient charging of the charging pile through efficient heat dissipation technology and precise control strategy, and also improves the safety and service life of the charging pile.

DC CHARGING PIlE SERIES

DC charging pile is an efficient charging facility for electric vehicles, which uses direct current (DC) to directly charge the vehicle battery, significantly reducing the charging time. Compared with traditional AC charging piles, DC charging piles are able to provide higher power output and can usually charge an EV to 80% of its capacity in 30 minutes, providing users with a convenient charging experience.

Extended reading

What are DC positive and negative contacts made of?

What are DC positive and negative contacts made of? The...

MIPI interface of DC charging pile display chip

MIPI interface of DC charging pile display chip Main component...

Introduction to the driver chip in the display

Introduction to the driver chip in the display Main component...

What are the components of a DC charging pile

This paper will introduce the main components of DC charging...

Dc charging pile power management chip interface

Dc charging pile power management chip interface The interface of...

THE ESSC Brand promise

Global supply

Our products sell well all over the world, covering many countries and regions, through the global logistics network, to provide customers with convenient purchasing experience.

Rigorous quality

We adhere to the highest quality control standards to ensure every product meets industry regulations and customer expectations, earning trust through consistent excellence.

Excellent service

With a customer-centric approach, we provide prompt responses, professional support, and personalized services, aiming to deliver the best user experience and long-term value.