Study on mechanical protection material of positive cap In modern...

The shell material of the battery shell

The battery case is an important part of the battery, and its main functions include protecting the internal components, improving the battery safety and extending the service life. The choice of shell material directly affects the performance, structural strength, weight and cost of the battery. This paper will discuss several commonly used battery shell materials and their characteristics.

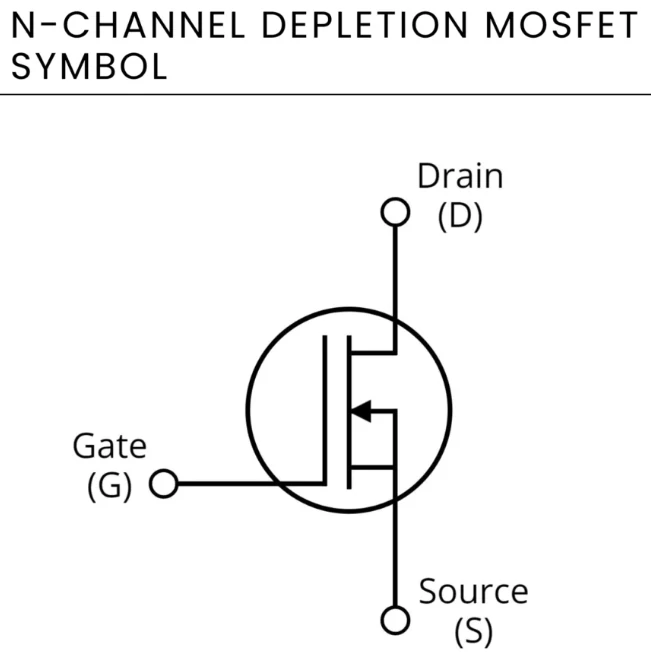

Aluminum alloy

Aluminum alloy is one of the most commonly used materials in battery shell housing. Its advantages include:

Lightweight: Aluminum alloy has a low density, which helps to reduce the overall weight of the battery, especially in weight sensitive applications such as electric vehicles, aluminum alloy provides a great advantage.

Corrosion resistance: the surface of aluminum alloy is easy to form a layer of dense oxide film, which can effectively resist the invasion of moisture and oxygen, prevent corrosion and oxidation.

Good thermal conductivity: The thermal conductivity of aluminum makes it conducive to the heat dissipation of the battery during charging and discharging, reducing the risk of overheating and keeping the battery within the optimal operating temperature range.

Easy to process: Aluminum alloys can be processed through a variety of processes (such as extrusion, casting and welding), easy to realize complex designs, and ensure high strength and hardness.

However, aluminum alloys are relatively costly and may lack sufficient impact resistance in some cases.

plastic materials

Plastic materials, especially polymers such as polypropylene (PP) and polycarbonate (PC), are also widely used in battery cases. The advantages of plastic materials are:

Light weight: Plastic materials have low density and are lighter than metal materials, helping to reduce the weight of the battery.

Good electrical insulation: plastic itself is an excellent insulator, contributing to battery safety and reducing the risk of short circuits.

Strong impact resistance: the plastic shell has good impact resistance, which can effectively absorb the impact of external forces on the battery and reduce the risk of damage.

Lower cost: Compared to metal materials, plastics are usually more economical and can reduce production costs.

Despite the above advantages, plastic materials have relatively poor heat and weather resistance, which may lead to deformation or degradation in high temperature environments.

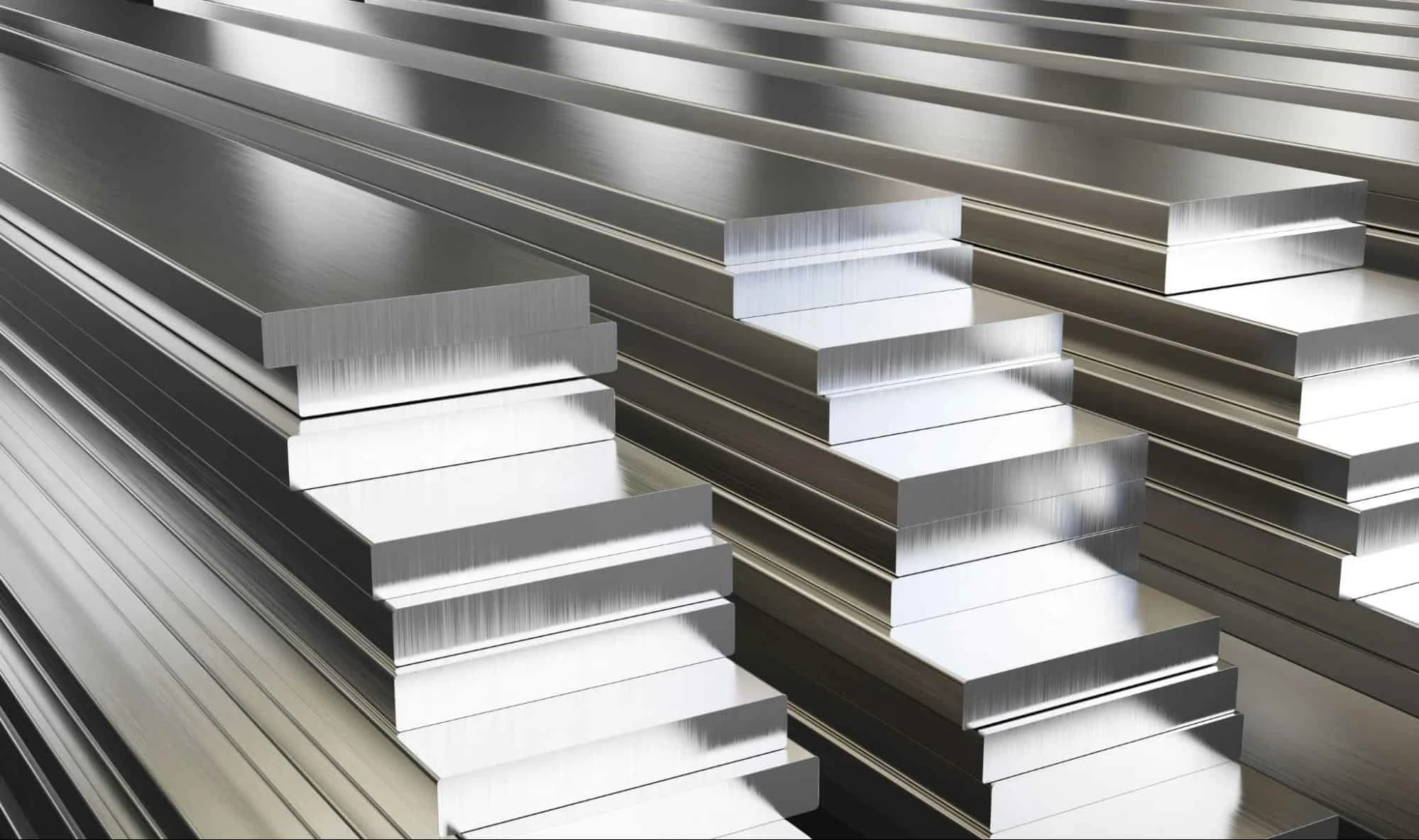

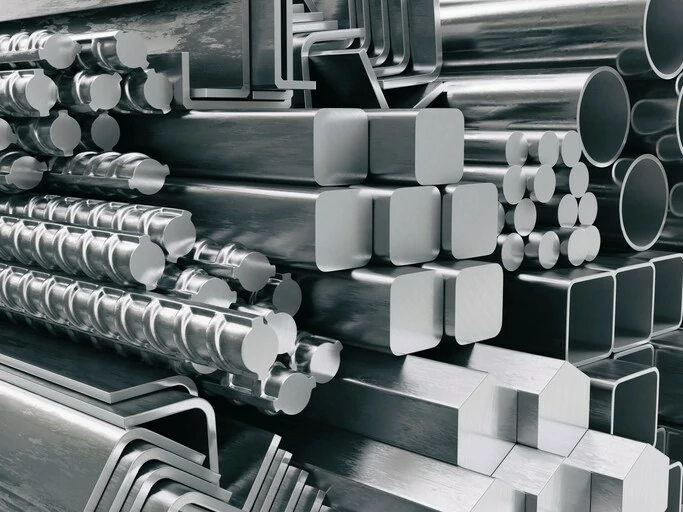

Steel

Steel, especially stainless steel, has also been adopted in certain battery applications due to its superior strength and corrosion resistance. Its features include:

High strength: Steel has excellent structural strength and compressive resistance, suitable for use in harsh environments, such as industrial equipment and large energy storage systems.

Excellent corrosion resistance: The dense oxide film formed on the surface of stainless steel enables it to resist corrosive media commonly found in the environment.

Good thermal conductivity: Steel has good thermal conductivity, which helps in heat dissipation management.

However, the heavy weight of steel is usually not suitable for weight-sensitive applications. Four, composite materials

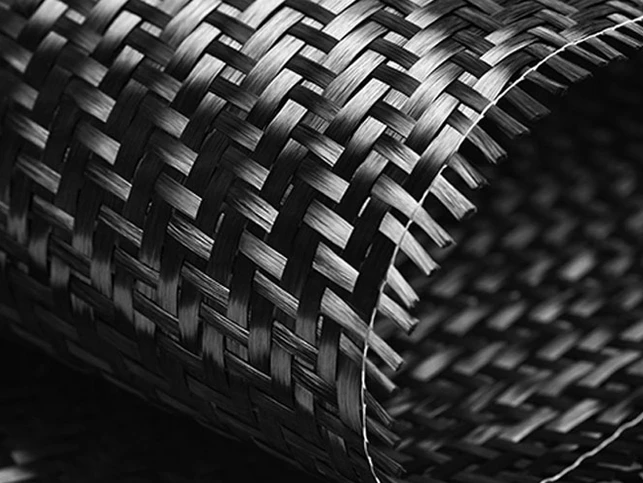

composite materials

Composite materials are high performance materials improved on the basis of traditional materials, which have gradually attracted attention in the application of battery shell in recent years. Composite materials combine the advantages of metal and plastic, and their characteristics include:

Strength and lightweight: Composite materials can maintain high strength and low weight at the same time, suitable for aerospace and high-performance electric vehicles and other fields.

Good processing performance: the composite material can be processed by molding, pultrusion and other processes, with design flexibility.

High temperature resistance: Some composites perform well in high temperature environments and are suitable for demanding applications.

Despite the high cost of composites, the performance advantages they offer are making them an increasing choice in some high-end applications.

Home energy storage product series

A lithium battery pack for home energy storage systems, which is compatible with solar panels and the sun The inverter can work together with the power grid to power household appliances, and it can also be used as a For off grid systems.

Extended reading

Safety protection level of battery pack

Safety protection level of battery pack Battery packs are widely...

THE ESSC Brand promise

Global supply

Our products sell well all over the world, covering many countries and regions, through the global logistics network, to provide customers with convenient purchasing experience.

Rigorous quality

We adhere to the highest quality control standards to ensure every product meets industry regulations and customer expectations, earning trust through consistent excellence.

Excellent service

With a customer-centric approach, we provide prompt responses, professional support, and personalized services, aiming to deliver the best user experience and long-term value.