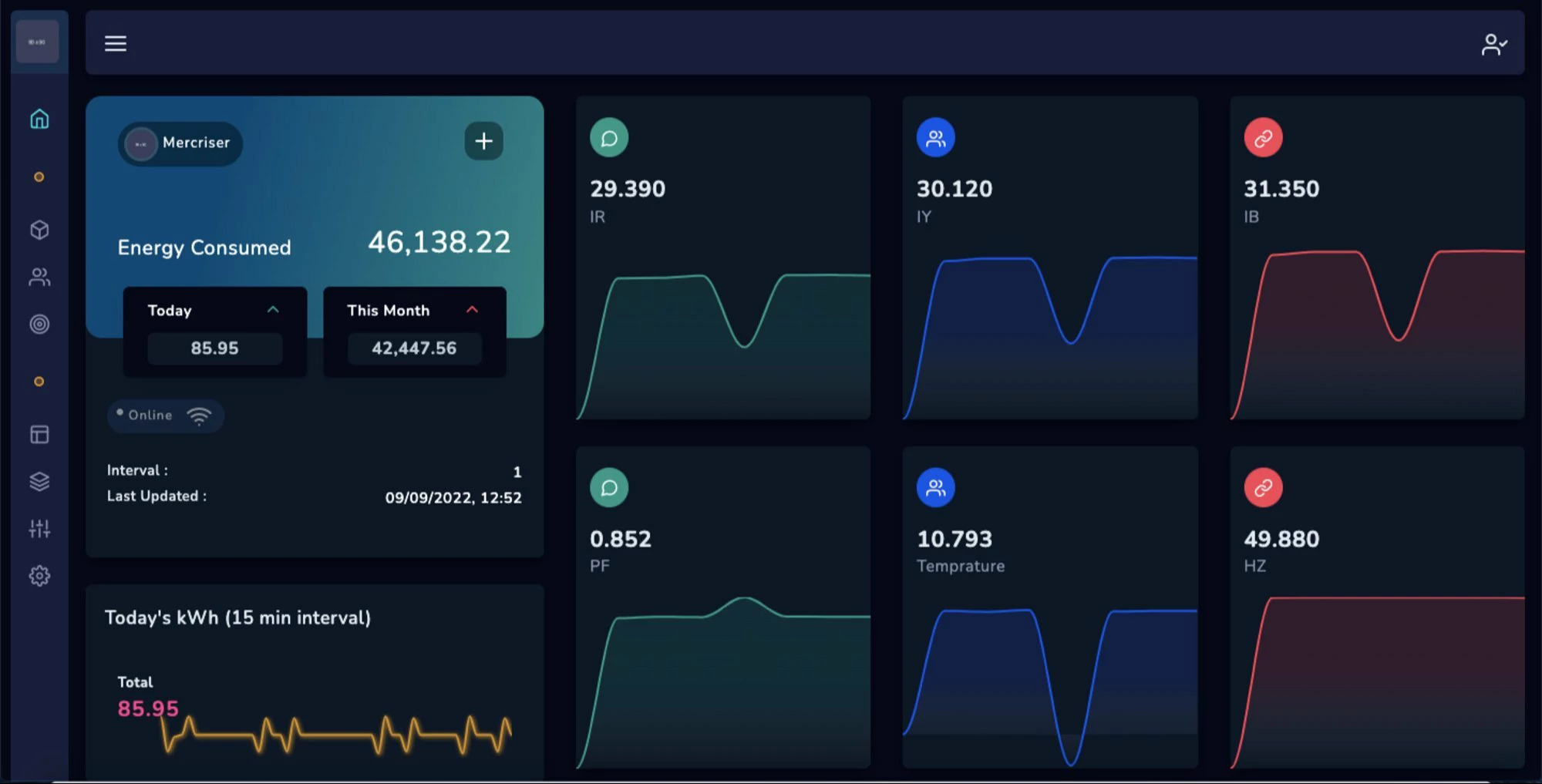

EMS An energy management system, or EMS, is a collection...

The material of the battery pack shell

As an important part of the battery system, the battery pack housing carries a variety of functions, including protecting the internal battery cells, providing structural support, cooling, and ensuring safety. In order to achieve these functions, the material choice of the shell is crucial. This paper will discuss several materials commonly used in battery pack housing and their characteristics and applications.

plastic materials

Polypropylene (PP)

Polypropylene is a commonly used plastic material in battery pack encloses and is favored for its good chemical resistance, strength, and toughness. PP material is light and easy to process, very suitable for mass production. In addition, its lower cost makes it a cost-effective option.

Polycarbonate (PC)

Polycarbonate is known for its excellent impact resistance and transparency, and is often used in battery pack casings that require good visibility. PC material has excellent temperature and weather resistance, suitable for use in high temperature environment, so it is widely used in electric vehicles and high-performance battery systems.

Polyester (PET)

Polyester is gaining popularity in battery pack housing, especially in terms of sustainability. PET can be recycled, which not only helps reduce the burden on the environment, but also has good electrical insulation and chemical resistance, which can effectively protect the internal battery cell.

metal materials

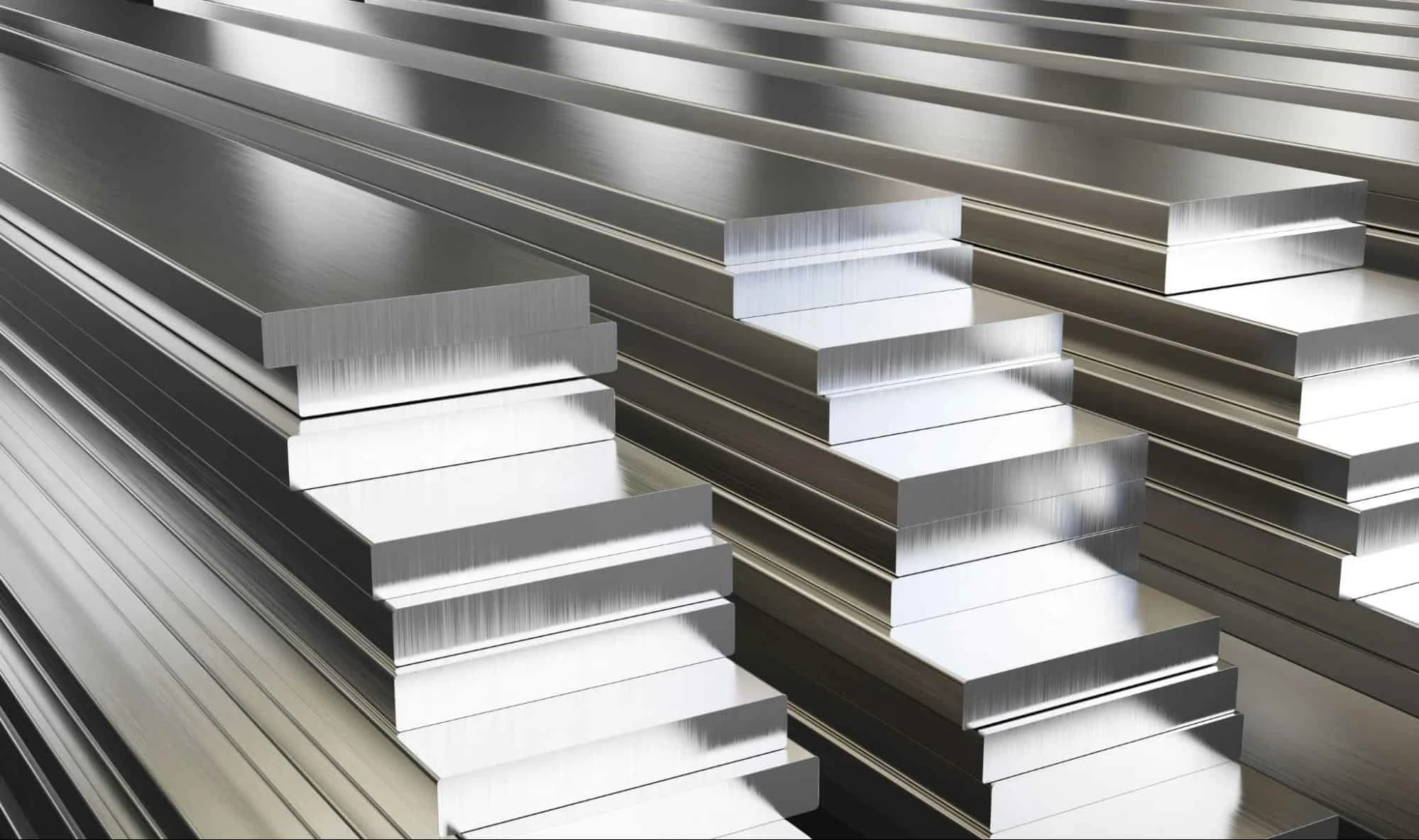

Aluminum alloy

Aluminum alloy is an ideal material for battery pack housing, which is widely used in electric vehicles and energy storage systems because of its light weight, high strength and good heat dissipation. The mechanical strength and corrosion resistance of aluminum alloys enable their use in a variety of environments. At the same time, aluminum's recyclability makes it popular in manufacturing.

Stainless steel

Stainless steel is known for its resistance to corrosion and high temperatures, and is often used in battery packs that require extreme safety. In some high-power battery systems, stainless steel enclosures can effectively prevent accidents caused by overheating or overvoltage.

composite materials

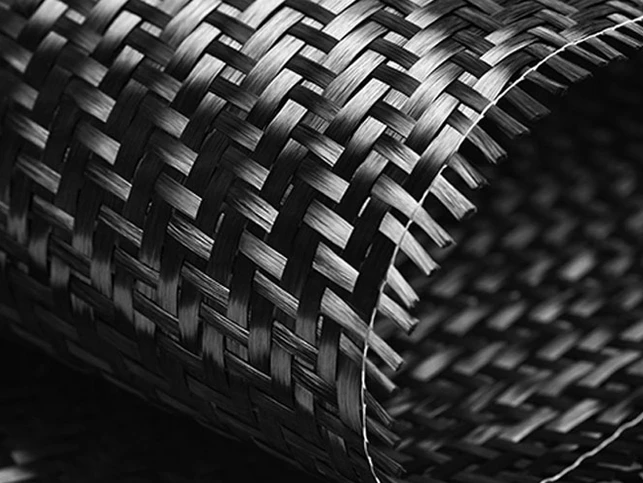

Carbon fiber composite

Carbon fiber composites have become a popular choice for high-end battery pack casings due to their lightweight and high strength. Especially in aerospace and high-performance electric vehicles, carbon fiber can provide superior strength and excellent thermal management performance. However, the high cost of carbon fiber limits its general application.

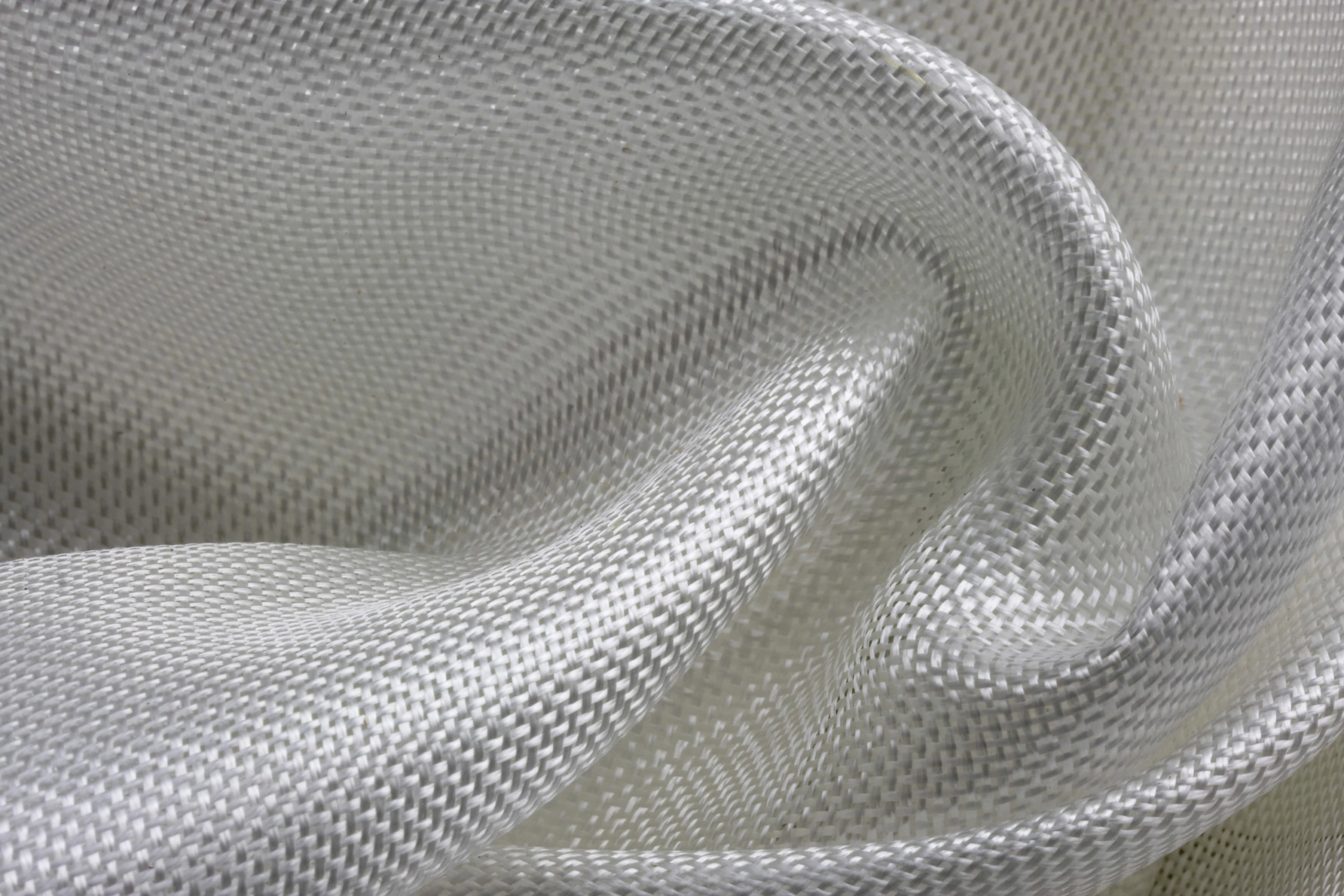

Glass fiber composite material

Glass fiber composites have excellent mechanical properties and chemical resistance, and are suitable for various environments. The lower cost of glass fiber compared to carbon fiber makes it a common choice for medium and high-end products, especially in electric energy storage and industrial battery systems.

Rubber is also sometimes used in battery packs, especially for sealing and shock proofing. The softness and elasticity of rubber allow it to effectively absorb shocks and protect sensitive battery cells. In addition, special rubber (such as silicone rubber) also has good heat and cold resistance, suitable for extreme environments.

Influencing factors of material selection

The choice of battery pack housing material is influenced by a variety of factors, including:

Battery types: Different types of batteries (such as lithium-ion batteries, lead-acid batteries, etc.) have different requirements for housing materials.

Application scenarios: Industrial applications and consumer electronics may have different requirements for materials, with the former placing more emphasis on durability and safety, and the latter on lightness and cost.

Environmental factors: the shell needs to adapt to the temperature, humidity, chemical media and so on of the working environment. This requires the material to have sufficient durability and adaptability.

Conclusion

The material selection of the battery pack shell directly affects the performance, safety and service life of the battery. With the continuous progress of technology, the application of new materials and new technologies will further promote the development of battery pack housing. Choosing the right materials can not only improve the overall efficiency of the battery, but also create a wider space for the sustainability of the battery. Understanding the material properties of battery pack encloses is essential for designing and manufacturing high performance battery systems.

Home energy storage product series

A lithium battery pack for home energy storage systems, which is compatible with solar panels and the sun The inverter can work together with the power grid to power household appliances, and it can also be used as a For off grid systems.

Extended reading

Single cell internal resistance test

Single cell internal resistance test With the continuous development of...

THE ESSC Brand promise

Global supply

Our products sell well all over the world, covering many countries and regions, through the global logistics network, to provide customers with convenient purchasing experience.

Rigorous quality

We adhere to the highest quality control standards to ensure every product meets industry regulations and customer expectations, earning trust through consistent excellence.

Excellent service

With a customer-centric approach, we provide prompt responses, professional support, and personalized services, aiming to deliver the best user experience and long-term value.