Flexible Graphite Composite Electrical Grounding Material (FGCGM) in Grounding Contacts...

The introduction of radiator in DC charging pile rectifier

The heat sinks in the rectifiers of DC charging piles are crucial for maintaining the normal operation and extending the service life of the charging piles. Here are six key applications and features of heat sinks

Main component

Heat Dissipation

The primary function of heat sinks is to dissipate the heat generated in the rectifier. Since rectifiers produce a significant amount of heat during operation, especially high-power rectifiers, effective cooling devices are needed to keep them within a safe operating temperature range.

Various Cooling Methods

DC charging piles employ various cooling methods, including forced air cooling, isolated air ducts, liquid cooling, and natural cooling. These cooling methods can be used individually or in combination to improve cooling efficiency.

Forced Air Cooling

Forced air cooling involves the use of fans to force air circulation for heat dissipation. Fans directly blow or draw air across heat-generating components (such as MOSFETs, transformers, inductors, and electrolytic capacitors), removing heat through forced convection.

Heat Pipe Heat Sinks

Some charging pile designs utilize heat pipe heat sinks, which take advantage of the efficient thermal conductivity of heat pipes to quickly transfer heat from the heat source to the surface of the heat sink, where it is then cooled by the air.

Combination of Fins and Fans

To enhance cooling efficiency, heat sinks are often used in conjunction with fins and fans. Fins increase the heat dissipation area, while fans accelerate air movement, helping to quickly disperse heat.

Energy Saving and Noise Reduction

When designing heat sinks, the needs for energy conservation and noise reduction must be considered. By optimizing the heat sink design and controlling fan speeds, it is possible to maintain good heat dissipation effects while reducing energy consumption and noise pollution.

In summary, heat sinks play an essential role in the rectifiers of DC charging piles, ensuring that the charging piles can operate stably under various environmental conditions through a variety of cooling methods.

DC CHARGING PIlE SERIES

DC charging pile is an efficient charging facility for electric vehicles, which uses direct current (DC) to directly charge the vehicle battery, significantly reducing the charging time. Compared with traditional AC charging piles, DC charging piles are able to provide higher power output and can usually charge an EV to 80% of its capacity in 30 minutes, providing users with a convenient charging experience.

Extended reading

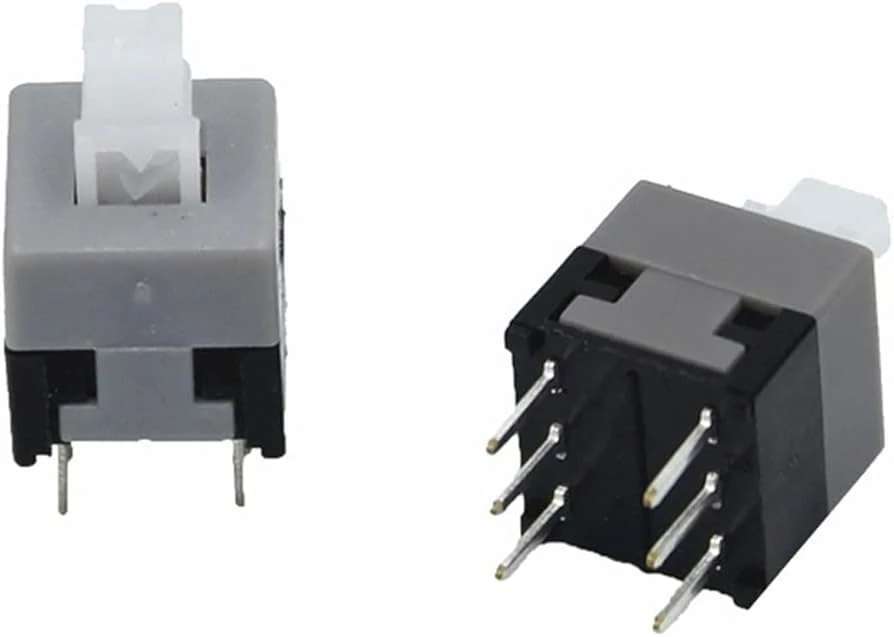

Introduction of microswitch in electronic locking mechanism of gun muzzle of DC charging pile

Introduction of microswitch in electronic locking mechanism of gun muzzle...

Introduction of unlocking process in electronic locking mechanism of gun muzzle of DC charging pile

Introduction of unlocking process in electronic locking mechanism of gun...

Introduction to nylon material in release button

Introduction to nylon material in release button Main component The...

The temperature detection function of charge control chip is introduced

The temperature detection function of charge control chip is introduced...

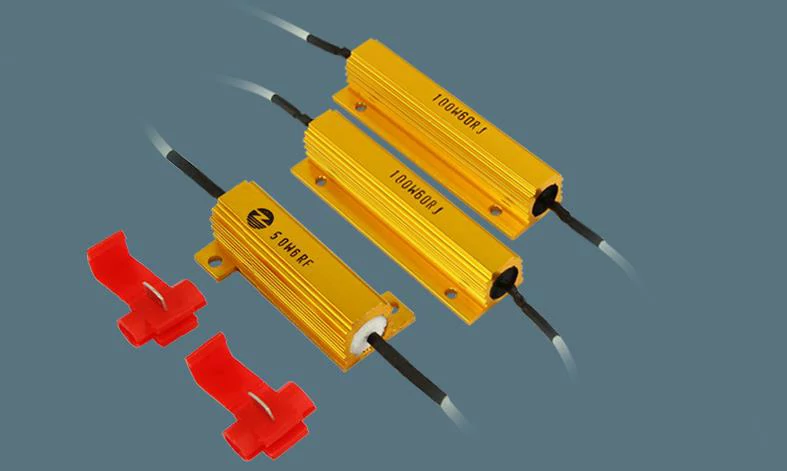

The introduction of resistors in DC charging pile rectifier

The introduction of resistors in DC charging pile rectifier Resistors...

THE ESSC Brand promise

Global supply

Our products sell well all over the world, covering many countries and regions, through the global logistics network, to provide customers with convenient purchasing experience.

Rigorous quality

We adhere to the highest quality control standards to ensure every product meets industry regulations and customer expectations, earning trust through consistent excellence.

Excellent service

With a customer-centric approach, we provide prompt responses, professional support, and personalized services, aiming to deliver the best user experience and long-term value.