The function of the positive cap of lithium iron phosphate...

The insulation protection of battery packs

The insulation protection of battery packs is an important part to ensure the safe and stable operation of battery packs, especially in applications with high voltage and high energy density such as electric vehicles and energy storage systems. They play a key role in the design of battery packs, enhancing their overall performance and safety by providing electrical insulation, thermal management, and structural protection. This article will deeply explore the function, material selection, design considerations, and importance of battery pack insulation protection in modern applications.

Function of insulation protection

Electrical insulation: The primary function of insulation protection is to prevent electrical short circuits between different battery cells in the battery pack or between them and the housing. This is particularly important for high-voltage battery packs to prevent current jumper from initiating short circuits.

Thermal management: Insulation in the battery pack also helps to manage heat flow, avoid hot spots and balance the temperature profile across the pack, thereby preventing overheating and thermal runaway.

Protection: provide support for the battery pack against mechanical shock and vibration. Insulation protection helps to ensure the stability and integrity of the battery during transportation and use.

Environmental protection: Protects the battery pack from external environmental factors (such as moisture, dust), extending system life and improving reliability.

Material selection

Polymer materials

such as polyimide (Kapton), polycarbonate, etc., with good electrical insulation performance, heat resistance and mechanical strength.

Ceramic materials

Used in environments requiring high temperature resistance, ceramic insulation materials can provide stable insulation performance under high temperature conditions.

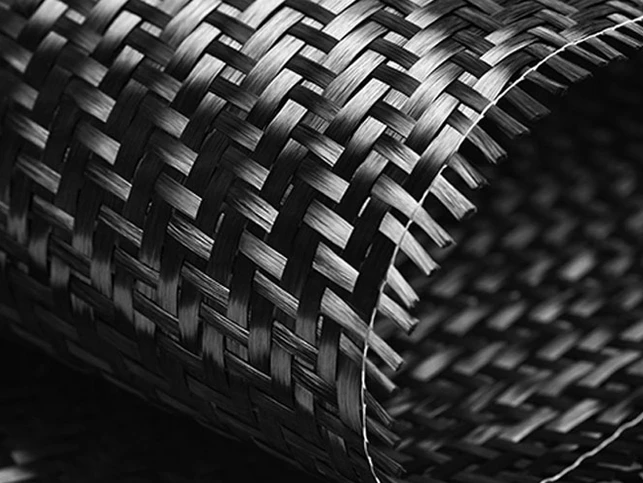

Composite

combines the advantages of polymer and fiber reinforced materials to provide high strength and low weight, suitable for weight and space sensitive applications.

Design Considerations

Insulation thickness and configuration

Appropriate insulation thickness and configuration should be selected according to the voltage level and working environment of the battery pack to ensure that it can effectively prevent electrical failure.

Heat dissipation performance

The thermal conductivity of the insulation needs to be carefully balanced to provide adequate insulation while supporting effective heat dissipation.

Mechanical strength

The resistance of the material to pressure, shock and vibration is considered to ensure the protection of the battery pack structure under extreme conditions.

Chemical stability

The material should be resistant to potential chemical corrosion such as electrolyte leakage to extend battery life.

The importance of insulation protection

Improve safety: The main value of insulation protection is to greatly reduce the possibility of short circuit, fire and other safety accidents.

Enhanced reliability and durability: Extended battery life and performance stability through effective electrical and environmental protection.

Suitable for various application scenarios: Different insulation designs can adapt to various environmental requirements, including severe temperature, humidity and mechanical load.

Application Examples

In electric vehicles, insulation protection is used within and between battery modules to ensure the safety of the system under driving conditions of high vibration and temperature variation. Energy storage systems typically face longer life cycles and higher voltage levels, which require highly reliable and durable insulation to support long-term stable operation.

Conclusion

The insulation protection of the battery pack not only directly affects the safety and performance of the battery, but also plays an important role in the overall design of the equipment. As battery technology evolves and the need for higher performance and safer battery systems increases, innovation in insulation materials and technologies will continue to drive progress in the field. By optimizing the design and material selection of insulation protection components, the efficiency, reliability and safety of battery packs can be further improved, and solid technical support can be provided for a wide range of industrial and civil applications.

Home energy storage product series

A lithium battery pack for home energy storage systems, which is compatible with solar panels and the sun The inverter can work together with the power grid to power household appliances, and it can also be used as a For off grid systems.

Extended reading

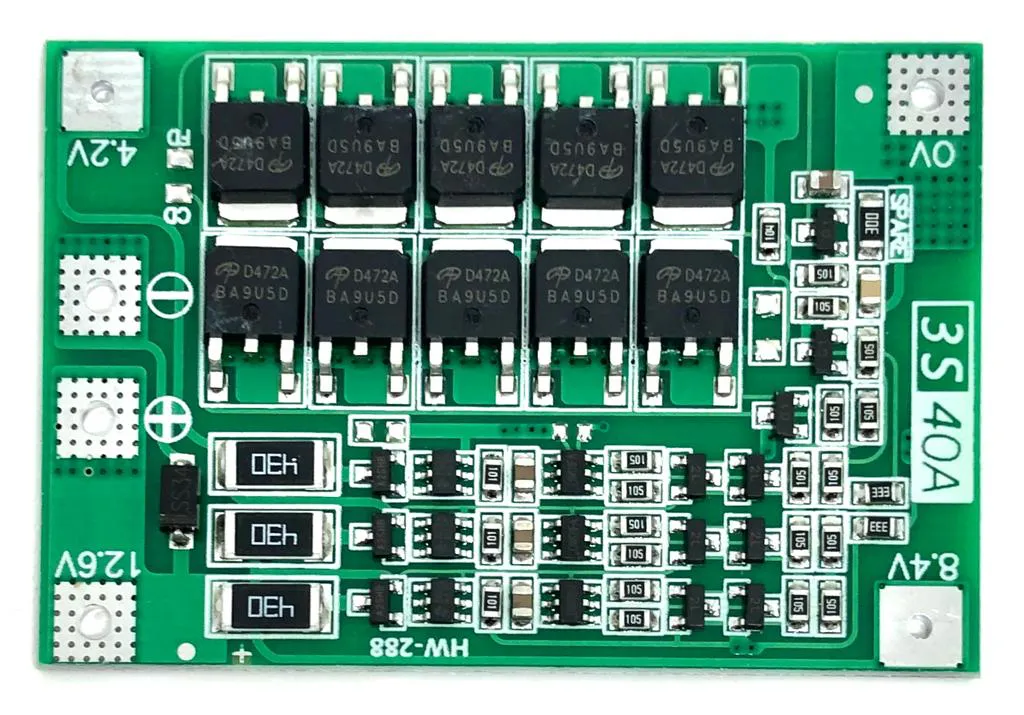

Centralized Battery Management System (BMS)

Centralized Battery Management System (BMS) With the popularity of electric...

THE ESSC Brand promise

Global supply

Our products sell well all over the world, covering many countries and regions, through the global logistics network, to provide customers with convenient purchasing experience.

Rigorous quality

We adhere to the highest quality control standards to ensure every product meets industry regulations and customer expectations, earning trust through consistent excellence.

Excellent service

With a customer-centric approach, we provide prompt responses, professional support, and personalized services, aiming to deliver the best user experience and long-term value.