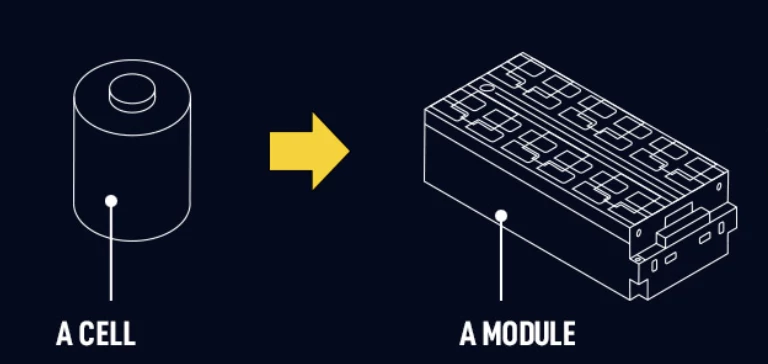

battery module process The battery module is a complete battery...

The inner liner material of the battery shell

The internal liner of the battery case plays an important role in the overall performance, lifetime and safety of the battery. It not only protects internal components from physical damage, but also provides additional insulation and shock resistance. This article will introduce several commonly used battery shell internal liner materials and their characteristics.

polyurethane

Polyurethane is a material widely used in the inner liner of batteries, and its advantages are mainly reflected in the following aspects:

Excellent buffering performance: Polyurethane has good elastic and buffering properties, which can effectively absorb shock and vibration and protect the sensitive components inside the battery from damage.

Wear resistance: polyurethane has strong wear resistance, can withstand long-term use of friction and wear.

Chemical stability: Polyurethane has good resistance to a variety of chemicals, can remain stable in a variety of working environments, and protect the battery interior from corrosion.

Superior sealing performance: polyurethane materials can effectively fill the joints and voids, providing good sealing and preventing moisture and pollutants from invading.

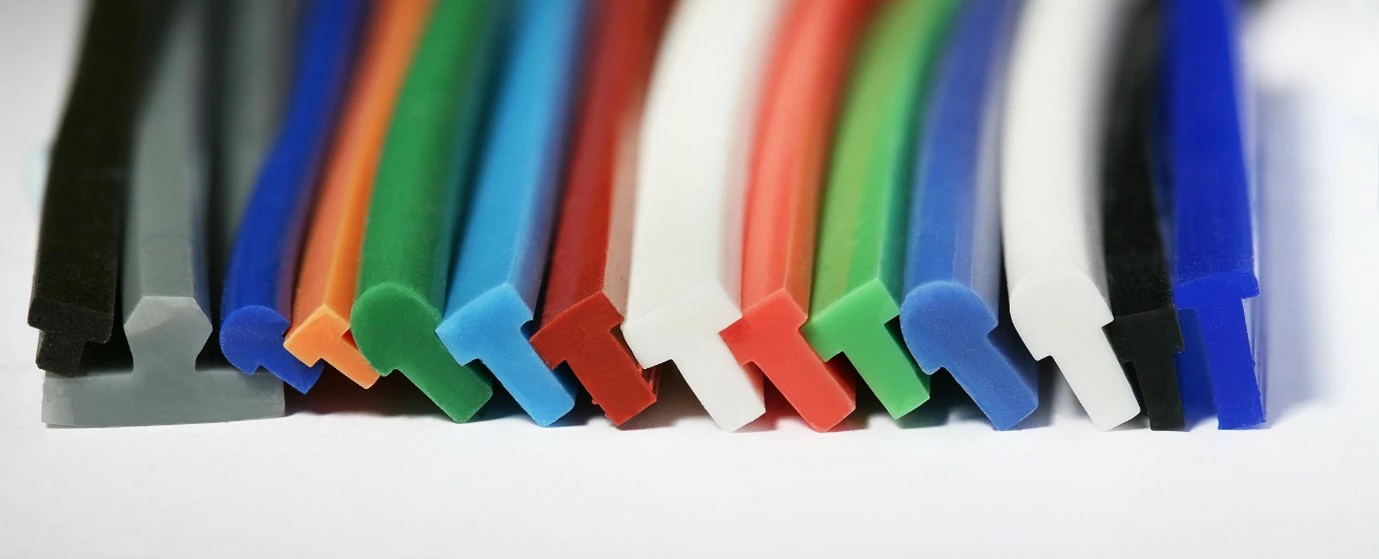

Rubber

Rubber is a classic shock-proof material, which is often used in the internal liner of batteries. Its main characteristics include:

Elasticity and toughness: rubber material has extremely high elasticity and toughness, which can effectively absorb impact and reduce the impact of vibration and impact caused by motion on the battery.

Insulation: Rubber is an excellent insulating material, which helps to improve the safety of the battery and prevent short circuits and current leakage.

Temperature resistance: many rubber materials can maintain good performance in high temperature and low temperature environment, to adapt to the needs of different working conditions.

Waterproof: Rubber has good sealing performance and can protect the internal components of the battery from moisture and other liquids.

However, aging and deterioration of rubber materials may become a problem in long-term use, so high-quality rubber materials need to be selected to ensure long-term stability.

EVA (ethylene vinyl acetate copolymer)

As a thermoplastic material, EVA has been paid more and more attention in the field of batteries. It has the following characteristics:

Flexibility: EVA has excellent flexibility and impact resistance, which can absorb the vibration generated by electronic components during charging and discharging.

Insulation: EVA is an excellent electrical insulation material that helps prevent current leakage and enhances the safety of the battery.

Water resistance: EVA has good moisture resistance, which can effectively prevent water from entering the inside of the battery shell.

Easy processing: EVA can be easily processed into different shapes and sizes through molding and forming processes to meet the needs of different battery designs.

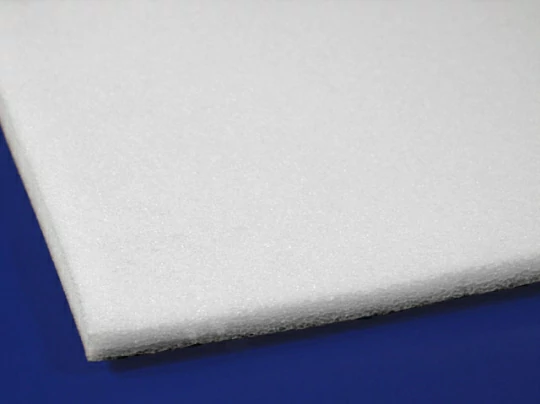

polyethylene foam

Polyethylene foam is a lightweight material that is often used as an internal lining for batteries. Its features include:

Good cushivity: The structure of polyethylene foam can effectively absorb shocks and provide excellent shock protection.

Lightweight: Polyethylene foam is extremely lightweight and helps reduce battery weight, especially in weight-sensitive applications such as mobile devices and electric vehicles.

Chemical resistance: polyethylene has good resistance to a variety of chemicals and can maintain stable performance in some harsh environments.

Easy to process: polyethylene foam is easy to cut and shape to adapt to the design requirements of various battery shells.

conclusion

The inner liner material of the battery case plays a crucial role in the safety, performance and service life of the battery. Materials such as polyurethane, rubber, EVA and polyethylene foam have different characteristics to meet the needs of different battery designs. With the continuous progress of material science, more new types of pad materials may appear in the future to further improve the performance and safety of batteries. Battery designers need to consider the physical properties, chemical stability, and economy of materials to select the most appropriate internal liner material for the battery application.

Home energy storage product series

A lithium battery pack for home energy storage systems, which is compatible with solar panels and the sun The inverter can work together with the power grid to power household appliances, and it can also be used as a For off grid systems.

Extended reading

How to test the static voltage of a single battery

How to test the static voltage of a single battery...

The function of the positive cap of lithium iron phosphate monomer battery

The function of the positive cap of lithium iron phosphate...

THE ESSC Brand promise

Global supply

Our products sell well all over the world, covering many countries and regions, through the global logistics network, to provide customers with convenient purchasing experience.

Rigorous quality

We adhere to the highest quality control standards to ensure every product meets industry regulations and customer expectations, earning trust through consistent excellence.

Excellent service

With a customer-centric approach, we provide prompt responses, professional support, and personalized services, aiming to deliver the best user experience and long-term value.