EPS charging interface The EPS (Emergency Power Supply) charging interface...

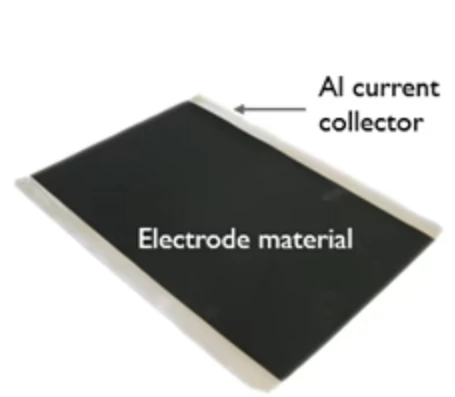

The electrode of EPS battery cell collects fluid

The electrode collector plays a crucial role in the battery cell of the EPS (Encapsulated power System), which is not only used to conduct electricity, but also to ensure effective battery performance and life. The selection of fluid collecting material has significant influence on the energy density, cycle life and electrochemical performance of the battery. The following is a detailed introduction to the electrode collector fluid in the EPS cell.

main content

Negative collector material - Copper

Copper is the main material of EPS battery's negative electrode fluid collector. Its advantages include:

High electrical conductivity: Copper has excellent electrical conductivity, which allows the current to flow quickly, thereby improving the energy output of the battery.

Excellent mechanical strength: The strength of copper is suitable for withstand mechanical stress when the battery is working, ensuring the stability of the fluid collection.

Corrosion resistance: Although copper may oxidize in some environments, its corrosion resistance can be enhanced with a suitable surface treatment.

Cost effective: Copper is relatively inexpensive to obtain and process, and easy to produce on a large scale.

However, copper may react with the electrolyte in a negative environment, so measures such as surface coatings need to be taken in the battery design to prevent the electrolyte from coming into direct contact with the copper.

Positive collector material - aluminum

Aluminum is a common material for the positive collector of EPS batteries, and its characteristics include:

Lightweight: The low density of aluminum can effectively reduce the overall weight of the battery, which is suitable for applications with high lightweight requirements.

Excellent electrical conductivity: Although the electrical conductivity of aluminum is lower than that of copper, its electrical conductivity is still sufficient to meet the requirements of the vast majority of lithium-ion batteries.

Excellent corrosion resistance: The naturally formed oxide layer on the surface of aluminum greatly enhances its corrosion resistance and is suitable for use in electrolytes.

Moderate cost: The raw material and processing costs of aluminum are relatively reasonable, which helps to control the overall battery manufacturing costs.

The aluminum collector can also be enhanced by alloying or surface treatment techniques to reduce the risk of failure at high temperatures or voltages.

Composite materials - Nickel alloy/nickel copper alloy

Nickel alloy and nickel-copper alloy as composite materials of fluid collection gradually received attention, mainly with the following advantages:

Strong corrosion resistance: Nickel has excellent corrosion resistance and can maintain battery performance under more demanding environmental conditions.

Good mechanical properties: Nickel alloys and nickel-copper alloys combine the advantages of copper and nickel to provide better mechanical strength and fatigue resistance for high power applications.

High temperature resistance: Compared with traditional materials, nickel-based alloys show superior performance in high temperature environments and are suitable for batteries under high operating conditions.

Improved electrical conductivity: The high electrical conductivity of nickel-copper alloy enables it to effectively reduce resistance losses and improve the overall performance of the battery.

The use of composite materials helps to improve the overall efficiency and life of the battery, especially in the case of frequent charging and discharging.

Coating material - carbon-based coating

Carbon-based coating as a coating for electrode fluid collection usually involves the following aspects:

Improved electrical conductivity: The high electrical conductivity of carbon materials can further enhance the conductivity of the collector, especially after coating the surface of the aluminum or copper substrate.

Prevent material migration: Carbon coating can prevent the migration of active substances in the battery, improve battery stability and cycle life.

Improved interface contact: The carbon-based coating improves the interface contact between the electrode and the electrolyte, helping to improve the charging efficiency of the battery.

Ultra-thin structure: Carbon-based coatings can be designed to be extremely thin without significantly increasing the weight or volume of the fluid collector, maintaining the advantage of lightweight.

The development of carbon-based coatings helps to improve the conductivity while increasing the corrosion resistance of the fluid collector.

Conductive polymer coating

Conductive polymer coatings are also increasingly used in battery collector fluids, and their characteristics include:

High conductivity: Conductive polymers such as polyaniline, polypyrrole, etc., can provide good conductivity, can enhance the overall performance of the battery.

Flexibility and adaptability: The conductive polymer coating is able to maintain a certain degree of flexibility and is suitable for a variety of shapes and types of battery designs.

Excellent adhesion: The adhesion between the polymer coating and the fluid collecting substrate is strong, ensuring that there is no peeling phenomenon during long-term use.

Environmentally friendly: Many conductive polymers can be synthesized using environmentally friendly methods that reduce the environmental impact of traditional synthetic materials.

Through reasonable design and application, conductive polymer coatings can greatly improve the performance and durability of EPS battery cells.

CONCLUSION

The electrode collecting fluid material in EPS cell is an important part of the battery performance. The negative fluid collector material is mainly copper, and the positive fluid collector material is mainly aluminum. The application of composite material further improves the performance of fluid collector. At the same time, the use of carbon-based coatings and conductive polymer coatings also provides a great improvement in the conductivity and durability of the battery. With the continuous progress of materials science, the development of fluid collecting materials will play a more critical role in battery technology in the future.

EPS BATTERY SERIES

The centralized power supply for fire emergency lighting is a kind of backup power supply equipment, which provides power guarantee for emergency lighting equipment to ensure that the on-site lighting equipment can operate normally in emergency situations such as fire. Provide a long-term backup power supply to meet the needs of the emergency lighting system.

Extended reading

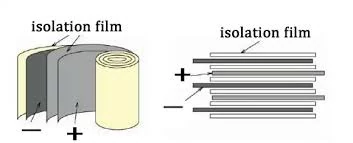

What is the specific role of the isolation membrane in the battery?

What is the specific role of the isolation membrane in...

What are the differences in security between different charging interfaces?

What are the differences in security between different charging interfaces?...

Safety valve and pressure relief device production material – aluminum alloy

Safety valve and pressure relief device production material – aluminum...

How do inverters ensure the stability and continuity of power output in EPS?

How do inverters ensure the stability and continuity of power...

How can composite materials improve performance in battery electrode collector?

How can composite materials improve performance in battery electrode collector?...

THE ESSC Brand promise

Global supply

Our products sell well all over the world, covering many countries and regions, through the global logistics network, to provide customers with convenient purchasing experience.

Rigorous quality

We adhere to the highest quality control standards to ensure every product meets industry regulations and customer expectations, earning trust through consistent excellence.

Excellent service

With a customer-centric approach, we provide prompt responses, professional support, and personalized services, aiming to deliver the best user experience and long-term value.