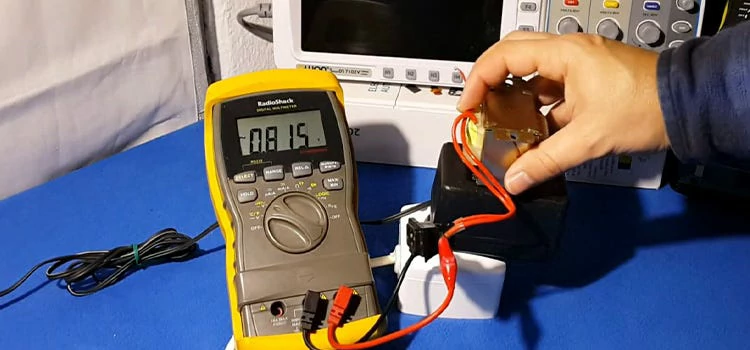

How to test the voltage drop of a single battery...

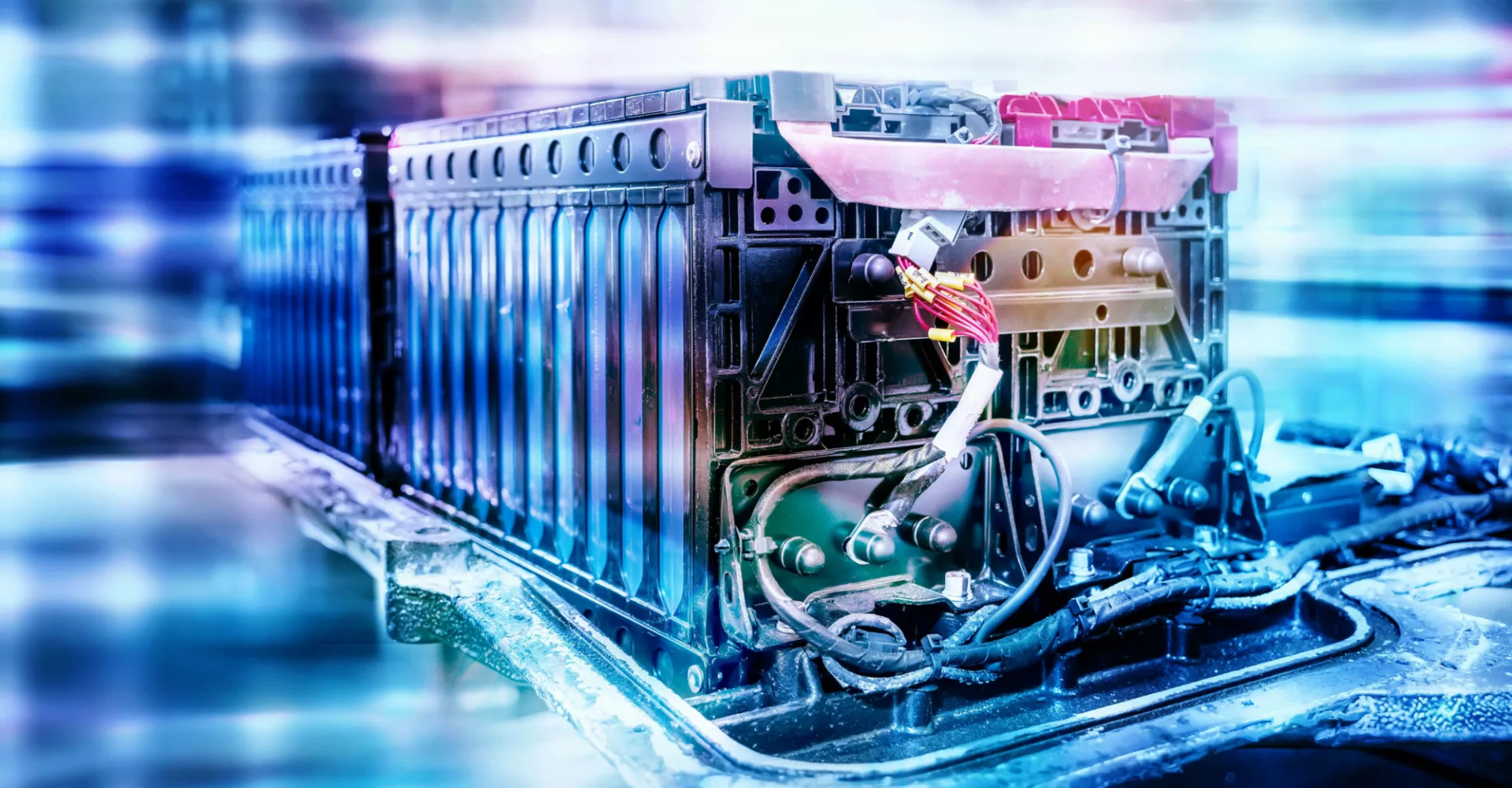

The connection bar of a battery pack

The connection bar of a battery pack is a key component in the design and assembly of a battery pack and is responsible for connecting individual battery cells to form a complete battery pack providing the required voltage and capacity. These connection bars not only determine the electrical performance of the battery pack, but also affect its overall safety, efficiency, and lifetime. The functions, material choices, design considerations, and their importance in battery packs will be described in this paper.

Function of the connection bar

Circuit connection: The main function of the connection bar is to connect multiple battery cells in series or parallel to achieve the required voltage and capacity. The series increases the total voltage of the battery pack and the parallel increases the total capacity.

Current transfer: Efficient transfer of current is the core task of the connection bar. The connection bar must be able to withstand and conduct large currents without overheating or significant energy loss.

Structural support: In addition to conducting current, the connection bars provide physical stability against vibration and mechanical stress, ensuring the integrity of the battery pack under various operating conditions.

Material selection

Copper

Copper is the most commonly used material due to its excellent electrical conductivity. Nickel plating on copper improves corrosion resistance and weldability.

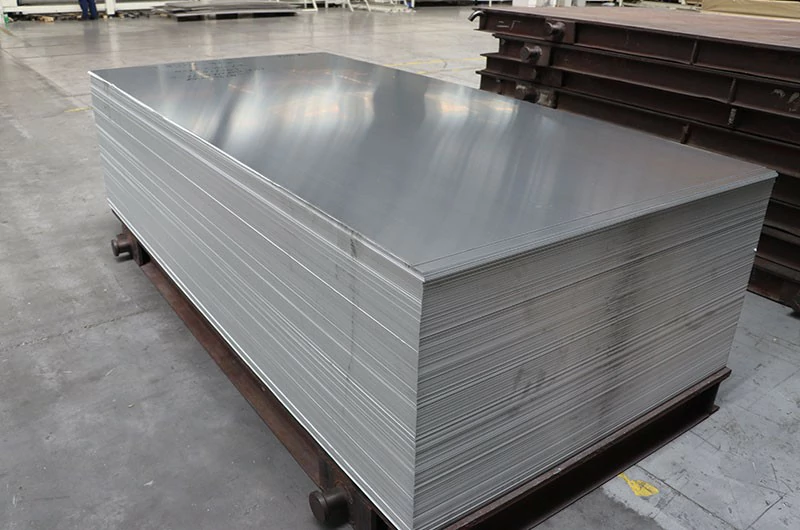

Aluminum

Although slightly less conductive than copper, lightweight, low-cost aluminum is also a common choice, especially suitable for weight-sensitive applications.

Aluminum-copper composites

Combine the advantages of copper and aluminum to balance electrical conductivity, cost, and weight.

Design Considerations

Cross-sectional area and shape

The cross-sectional area of the connecting strip determines its current carrying capacity and should be designed with the maximum current demand in mind. In terms of shape, the flat strip and curved strip should be designed according to the assembly space and electrical path.

Temperature management

In order to prevent overheating, the design needs to pay attention to the heat dissipation performance of the connecting strip, and if necessary, heat dissipation fins or other heat management measures can be added.

Mechanical properties

The connecting strip must have good mechanical strength to resist the mechanical stress in manufacturing, assembly and use, and avoid structural damage caused by vibration and impact.

Compatibility

The compatibility of the connecting strip material with the battery cell terminals is considered to ensure good electrical connection and long-term stability.

The importance of connection bars

Efficient energy transfer: high-quality connection strips can significantly reduce energy losses and improve the overall efficiency of the battery pack, so that the battery can release more available energy.

Safety: Good design and material selection can prevent overheating and arcing, reduce short circuit and fire and other safety hazards.

Reliability and life: High quality connection bars reduce resistance and thermal decay at the connection and extend the life of the battery pack.

Application Examples

In areas such as electric vehicles, energy storage systems, and consumer electronics, connection bars play an indispensable role. For example, in the electric vehicle battery pack, the connection bar needs to provide stable current transmission under high vibration and high temperature environment to ensure the performance and safety of the vehicle. However, in consumer electronic devices, the design of connection bars is more concerned with miniaturization and lightweight.

Conclusion

The connection bar is a key component in the battery pack, which directly affects its performance, efficiency and safety. In electric vehicles, renewable energy, and other demanding applications, the design and material selection of connection strips requires careful trade-offs to meet the specific requirements and environmental conditions of the system. In the future, with the development of battery technology and application requirements, the connection bar will also obtain more innovation and improvement in the field of advanced materials and intelligent design.

Home energy storage product series

A lithium battery pack for home energy storage systems, which is compatible with solar panels and the sun The inverter can work together with the power grid to power household appliances, and it can also be used as a For off grid systems.

Extended reading

Manufacturing process of lithium iron phosphate battery

Manufacturing process of lithium iron phosphate battery Lithium iron phosphate...

THE ESSC Brand promise

Global supply

Our products sell well all over the world, covering many countries and regions, through the global logistics network, to provide customers with convenient purchasing experience.

Rigorous quality

We adhere to the highest quality control standards to ensure every product meets industry regulations and customer expectations, earning trust through consistent excellence.

Excellent service

With a customer-centric approach, we provide prompt responses, professional support, and personalized services, aiming to deliver the best user experience and long-term value.