Introduction of battery pack components A battery pack consists of...

The connecting piece is welded to the top cover

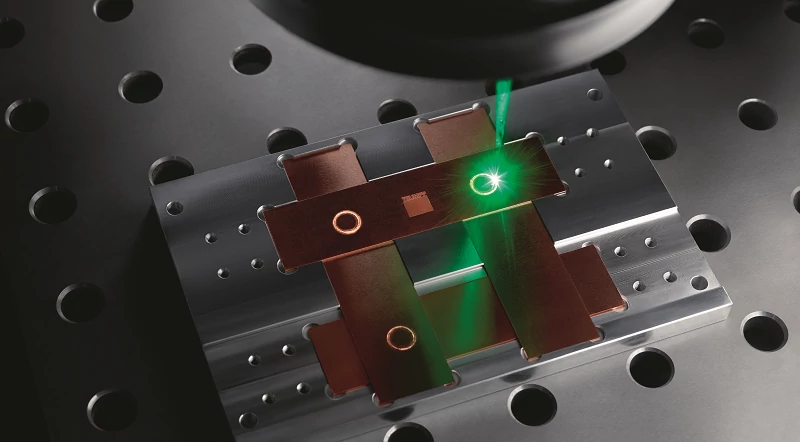

The copper/aluminum soft connection is welded to the inner surface of the pole column corresponding to the top cover by continuous laser, and the weld mark needs to be protected by adhesive.

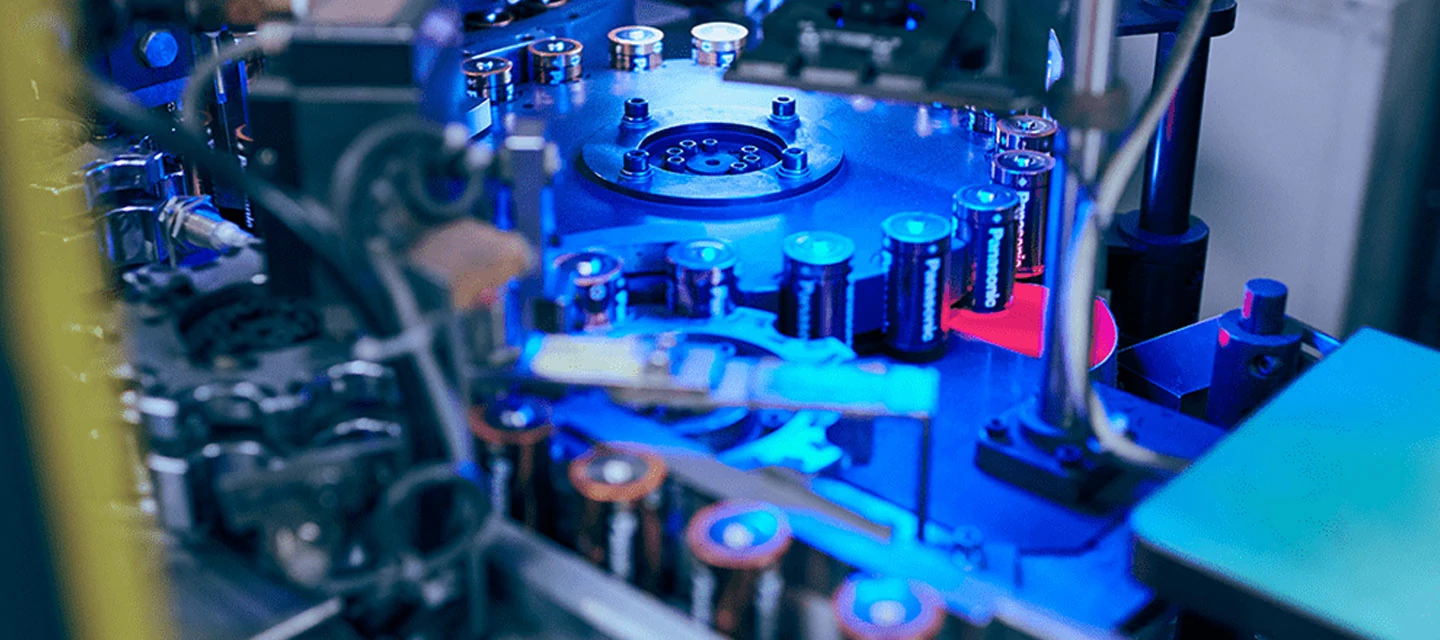

Equipment: single fiber + galvanometer laser welder sequence

Purpose: the core and the top cover welding connection.

Key quality control points of the process: deep baking, virtual welding, welding penetration, explosion point, insufficient residual area, insufficient tension, dust pull.

Pole-ear bending: pole-ear bending, the two cells are stacked together.

Core adhesive: After two batteries are stacked together, tape is affixed to ensure the combination.

process

Battery Cell Loading: Placing the battery cell on the production line.

Battery Cell Scanning: Scanning the battery cell to confirm its information.

If the test result is NG (not acceptable), NG Removal is performed.

Battery Cell Clamping: The battery cell is fixed on the clamping device in preparation for welding.

Top Cover Loading: Placing the top cover on the production line.

Top Cover Scanning: Scanning the top cover to confirm its information.

If the test result is NG (not acceptable), NG Removal is performed.

Top Cover Clamping: The top cover is fixed to the fixture in preparation for welding.

Laser Welding: the core and the top cover are laser welded.

Weld Mark Cleaning: clean the marks after welding.

Weld Mark CCD Inspection: Visual inspection of weld marks using a CCD camera.

If the solder print CCD test result is NG (unqualified), NG Removal (NG Removal) is performed.

If the solder printing CCD test result is unqualified, solder printing and gluing will be carried out.

Weld Mark CAD Inspection: Use CAD software to inspect weld marks.

If the solder print cad test result is NG, the same NG removal is performed.

Manual Inspection: Perform manual visual inspection to ensure assembly quality.

If the result of manual visual examination is NG, NG removal is performed.

Core Pressing and Molding: the electric core is put into the mold for pressing.

Side Adhesive Application: apply glue to the side of the cell.

Top Cover Scanning: Scan the top cover again to confirm the information.

If the test result is NG (not acceptable), NG Removal is performed.

Battery Cell Unloading: The removal of assembled battery cells from the production line.

Home energy storage product series

A lithium battery pack for home energy storage systems, which is compatible with solar panels and the sun The inverter can work together with the power grid to power household appliances, and it can also be used as a For off grid systems.

Extended reading

Preliminary Soldering before Housing

Preliminary Soldering before Housing The good battery core is loaded...

Application and advantages of polypropylene in lithium battery separator

A highly integrated backup power solution for solar home energy...

THE ESSC Brand promise

Global supply

Our products sell well all over the world, covering many countries and regions, through the global logistics network, to provide customers with convenient purchasing experience.

Rigorous quality

We adhere to the highest quality control standards to ensure every product meets industry regulations and customer expectations, earning trust through consistent excellence.

Excellent service

With a customer-centric approach, we provide prompt responses, professional support, and personalized services, aiming to deliver the best user experience and long-term value.