Product testing Product testing is a key link to ensure...

Shell material

Low-speed car battery shell material is mainly divided into metal shell and plastic shell. Metal housing (such as aluminum alloy) has stronger impact resistance and heat dissipation performance, suitable for high-performance batteries, but the weight is larger; Plastic housing (such as ABS, PC) is lightweight, low cost, suitable for popular batteries, and relatively weak protection. The selection of different materials requires a balance between protection, durability, heat dissipation and weight to suit different application scenarios.

Battery specification

The material of the battery case directly affects the safety, durability and service life of the battery. The high quality housing provides better protection against battery failure or damage when subjected to shock, vibration, moisture or extreme temperatures, thus ensuring vehicle stability and reliability. The appropriate housing material not only improves the safety of the battery, but also optimizes the heat dissipation performance of the battery, extends the battery life, and ensures that the battery works efficiently in various environments.

Specific performance direction

Material type

Common shell materials include metal (such as aluminum alloy) and plastic (such as ABS, PC, etc.). Metal enclosures generally have greater impact resistance and heat dissipation, while plastic enclosures are generally lighter and less costly.

Protective performance

Volume and weight are directly related to battery portability and vehicle load performance. Smaller size and lighter weight help improve range, acceleration and handling flexibility, while providing users with a more convenient installation and maintenance experience.

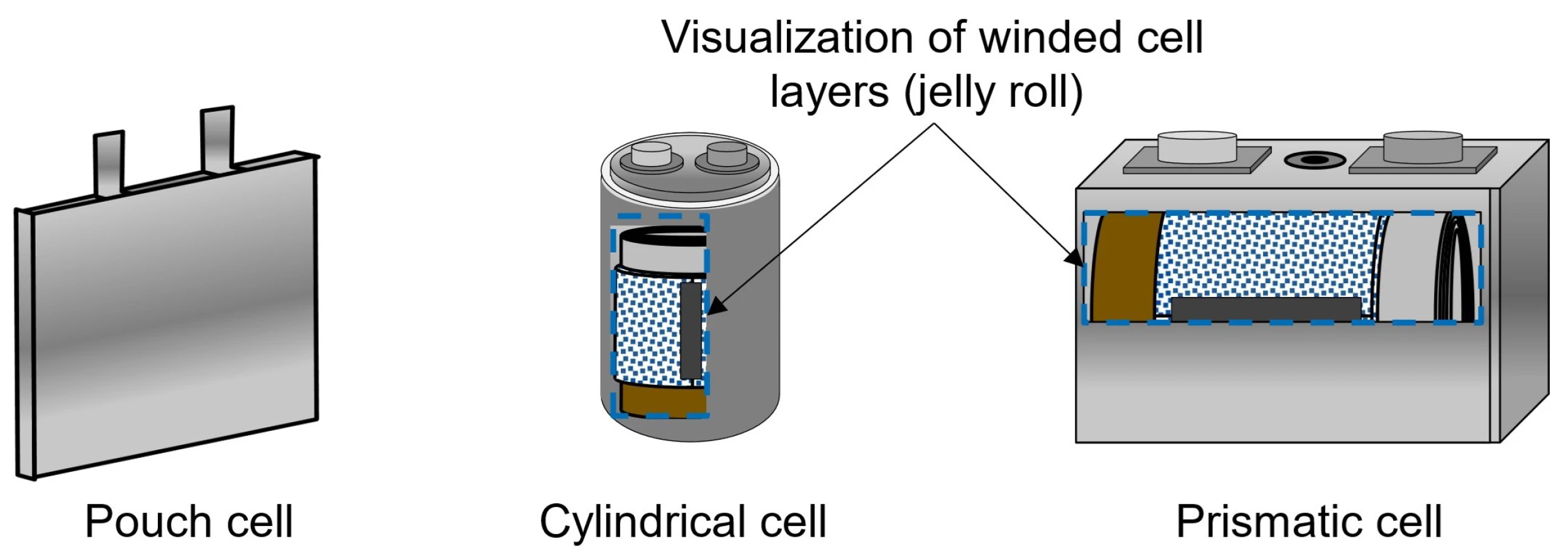

Battery type

The protective ability of the shell material includes waterproof, dustproof and seismic. High-end batteries may use higher performance materials (such as water resistance levels up to IP67, IP68) to ensure the stable work of the battery in harsh environments.

Temperature resistance

Different shell materials perform differently in high and low temperature environments, and high temperature resistance materials can maintain the normal working temperature of the battery in extreme climates and improve the stability of the battery.

Weight and density

Metal enclosures are usually heavier, but provide better protection and heat dissipation; The plastic shell is lighter, helping to reduce the weight of the body.

low-speed car batteries

Low-speed vehicle battery is a kind of battery designed for low-speed electric vehicles, which has the characteristics of clean, environmental protection, high efficiency and economy, and is widely used in electric golf carts, low-speed electric vehicles (LSV), mobile vendors, campus transportation, cargo trucks and so on

Extended reading

Product packaging and delivery

Product packaging and delivery The packaging and delivery of battery...

Product information expansion

Product information expansion Understanding low-speed vehicle battery product information is...

Product composition

Low-speed lithium battery product composition Understanding the product composition of...

THE ESSC Brand promise

Global supply

Our products sell well all over the world, covering many countries and regions, through the global logistics network, to provide customers with convenient purchasing experience.

Rigorous quality

We adhere to the highest quality control standards to ensure every product meets industry regulations and customer expectations, earning trust through consistent excellence.

Excellent service

With a customer-centric approach, we provide prompt responses, professional support, and personalized services, aiming to deliver the best user experience and long-term value.