Introduction to the electrolyte of lithium iron phosphate battery Lithium...

Study on mechanical protection material of positive cap

In modern battery technology, lithium iron phosphate (LiFePO4) single battery is widely used in energy storage system and other fields because of its safety, high temperature stability and good cycle life. As an important part of the connection between the cathode material and the external circuit, the positive cap undertakes multiple functions of electrical connection, thermal management and mechanical protection. Therefore, the selection of appropriate mechanical protection materials is crucial to improve the overall performance and safety of batteries. In this paper, the mechanical protection material of the positive cap of lithium iron phosphate monomer battery will be discussed in detail, including the material type, performance and its influence on the battery performance.

the importance of mechanical protection materials

The positive cap is not only a protective barrier for the internal electrodes of the battery, but also an important part of the overall structural strength of the battery. The main functions of mechanical protection materials include:

Impact and compression strength: in extreme cases such as collisions and drops, the positive cap needs to have good impact and compression resistance to ensure that the battery is not damaged.

Prevent short circuit: Mechanical protection materials can effectively prevent the contact of internal components of the battery, reduce the risk of short circuit, and ensure the safe operation of the battery.

Thermal management: Some mechanical protection materials have thermal conductivity, which can help the battery dissipate heat and prevent performance degradation or safety hazards caused by excessive temperature.

Environmental isolation: The mechanical protection material can resist the external environment on the battery components, such as dust, moisture and gas, to ensure the stability of the internal environment of the battery.

commonly used mechanical protection materials

Polycarbonate (PC)

The polycarbonate material has good toughness, excellent impact resistance, and good transparency, which is convenient for visual inspection of the internal state of the battery. However, it has Relatively low heat resistance, easy to deform in high temperature environment.

Polypropylene (PP)

Polypropylene is a lightweight, chemically stable thermoplastic that is resistant to wear and is suitable for battery housing and protective caps. However, it has Relatively low impact resistance, brittle cracking may occur under extreme conditions.

Polyurethane (PU)

Polyurethane material is flexible, can effectively absorb impact energy, provide good protection, while the hardness and elasticity can be adjusted by different formulations. But it may be sensitive to certain chemicals, relatively weak temperature resistance.

Thermoplastic elastomer (TPE)

Combining the elasticity of rubber and the processability of plastic, it can restore the original state after multiple extrusion and deformation, providing lasting protection. Some types of TPE may lose strength in high temperatures or chemical environments.

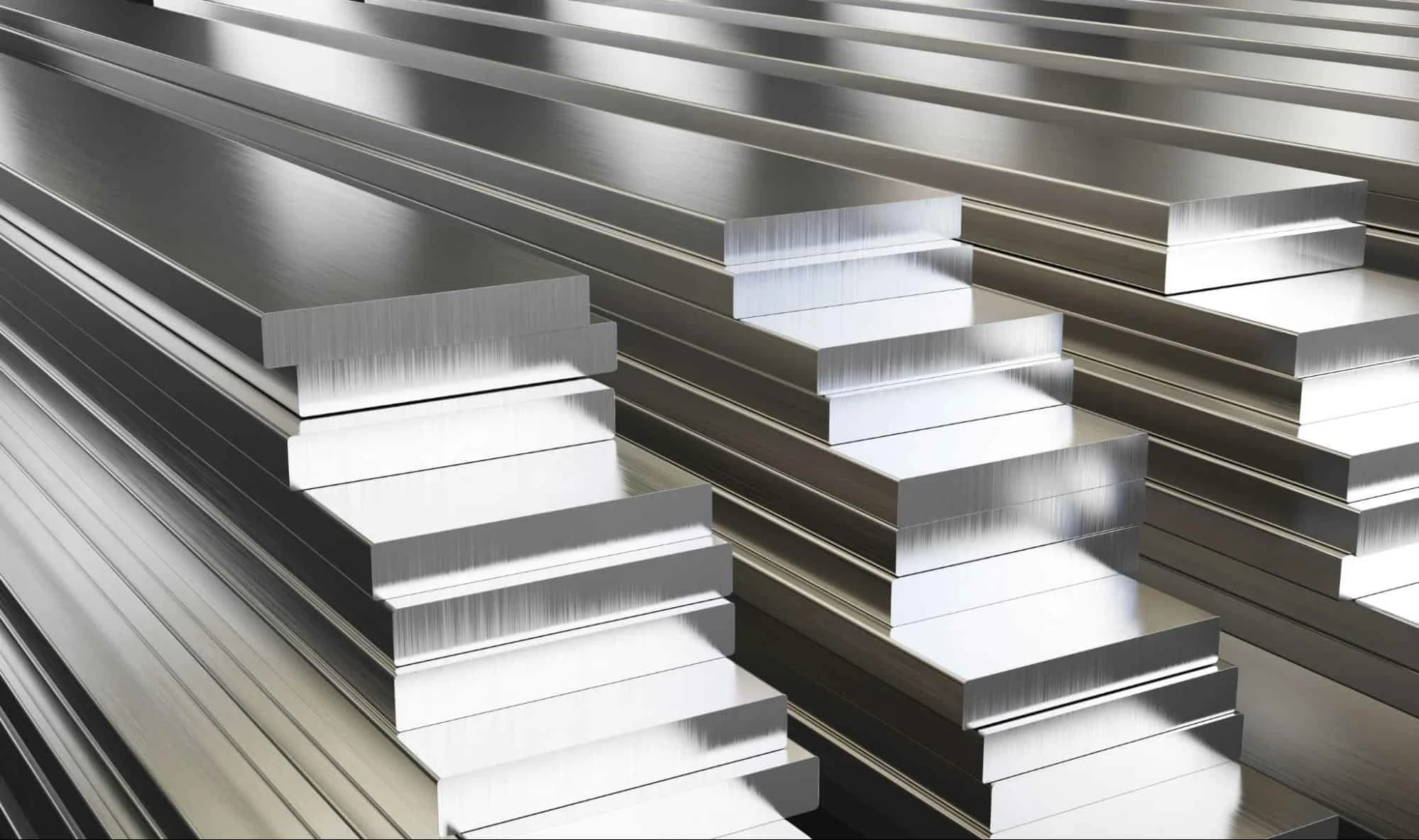

Aluminum alloy shell

Aluminum is strong, corrosion resistant and provides excellent mechanical protection for battery applications that require a high degree of safety. However, it has Heavy weight, increases the overall weight of the battery, may affect the energy density of the battery.

Influence of mechanical protection materials on battery performance

The selection of mechanical protection materials has a significant impact on the overall performance of lithium iron phosphate monomer batteries, mainly reflected in the following aspects:

Safety: The high strength mechanical protection material can effectively reduce the risk of damage when the battery is subjected to external impact, prevent leakage or short circuit caused by safety accidents.

Safety: The high strength mechanical protection material can effectively reduce the risk of damage when the battery is subjected to external impact, prevent leakage or short circuit caused by safety accidents.

Weight and volume: The choice of lightweight mechanical protection materials helps to improve the energy density of the battery, which is more suitable for weight and volume sensitive applications such as electric vehicles and portable devices.

Durability: ABRAsion-resistant and corrosion-resistant mechanical protection materials can extend the service life of the battery and reduce performance degradation caused by environmental impact.

Conclusion

The mechanical protection material of the positive cap plays a vital role in the lithium iron phosphate monomer battery, and the choice of its material directly affects the safety, performance and service life of the battery. With the continuous progress of technology, exploring and innovating new mechanical protection materials will be an important direction to improve the overall performance of batteries. By strengthening the research and development of materials, the future lithium iron phosphate monomer battery will be safer and more competitive.

Home energy storage product series

A lithium battery pack for home energy storage systems, which is compatible with solar panels and the sun The inverter can work together with the power grid to power household appliances, and it can also be used as a For off grid systems.

Extended reading

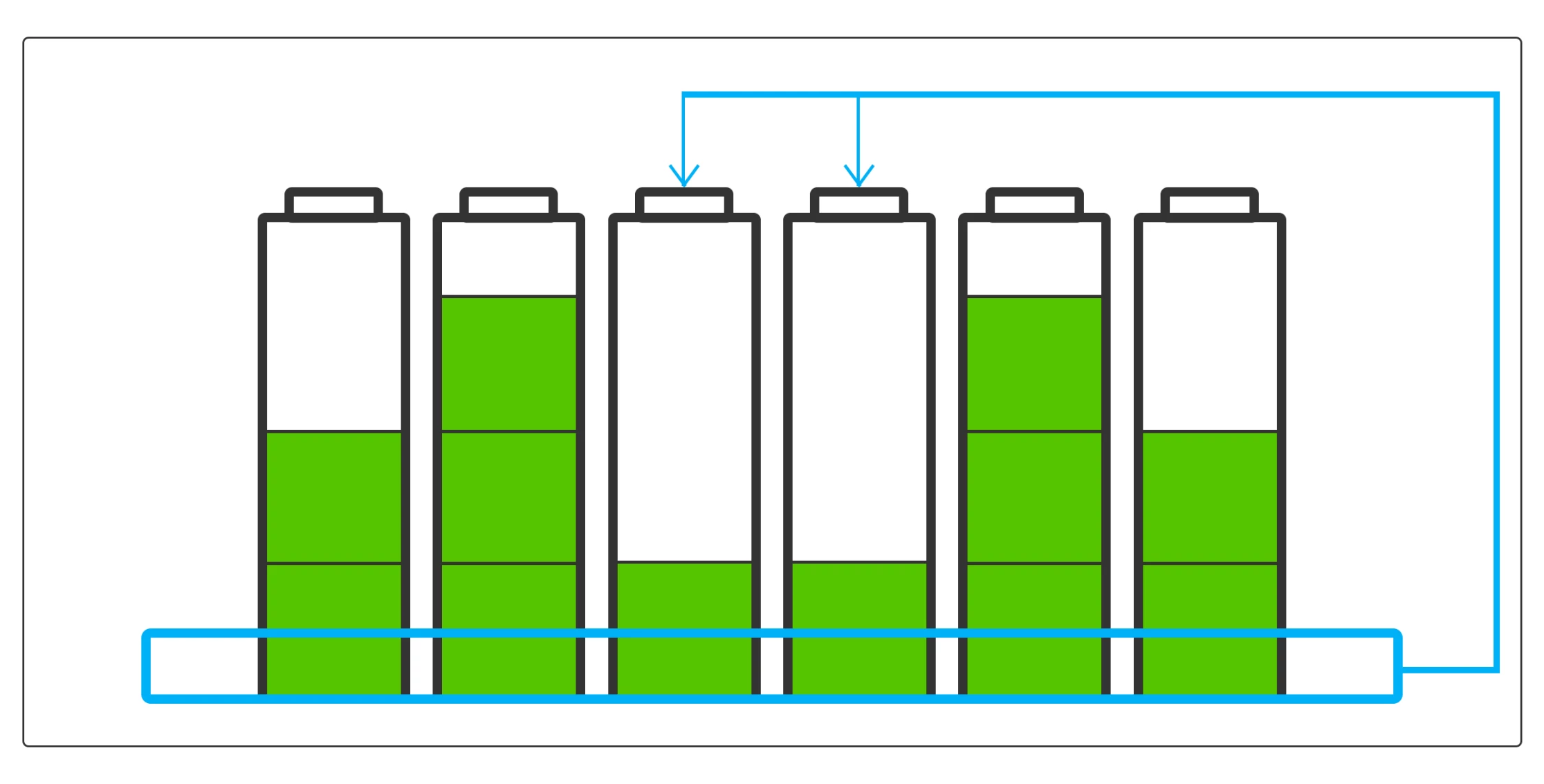

Passive Balanced Battery Management System (BMS)

Passive Balanced Battery Management System (BMS) With the rapid development...

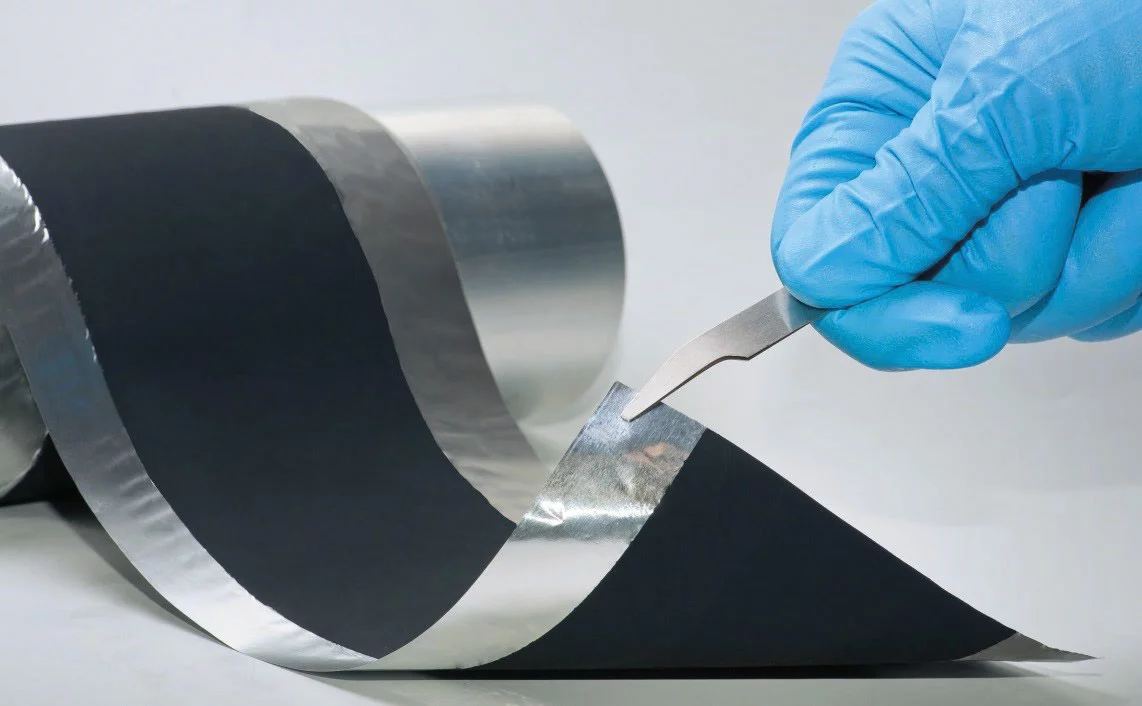

The introduction of the battery electrode

The introduction of the battery electrode The pole plate is...

THE ESSC Brand promise

Global supply

Our products sell well all over the world, covering many countries and regions, through the global logistics network, to provide customers with convenient purchasing experience.

Rigorous quality

We adhere to the highest quality control standards to ensure every product meets industry regulations and customer expectations, earning trust through consistent excellence.

Excellent service

With a customer-centric approach, we provide prompt responses, professional support, and personalized services, aiming to deliver the best user experience and long-term value.