Product testing Product testing is a key link to ensure...

Size and shape check

Size and shape inspection is an important part of battery quality control to ensure that the size and shape of the battery meet the design requirements and can be effectively integrated with the device or battery pack.

Size and shape check

Size and shape checks are fundamental to ensure that the battery can be properly connected to other devices or modules in practical applications. The precise size control ensures that the battery does not have poor fit or physical conflict during assembly, which helps to ensure the stability and safety of the battery system. Dimensional consistency also ensures maximum battery performance and avoids battery failure due to physical defects. In addition, size and shape checks are essential for quality consistency and product standardization in mass production, reducing the risk of later rework, repair or return.

Check content

Battery shape and size

Shape inspection: Ensure that the shape of the battery meets the design requirements, and there is no deformation, bending or irregular situation.

Size measurement: The battery length, width, height and other dimensions are checked by accurate measuring tools to ensure that the battery is not unqualified due to production errors during the production process.

Ensure that the battery form and size are fully compatible with the design drawings, assembly requirements, and the device or battery module used.

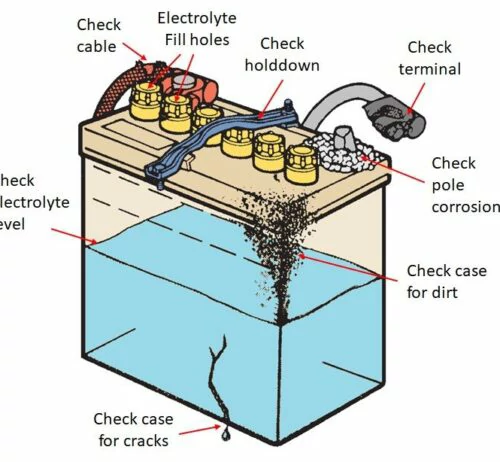

Contact port and electrode dimensions

Check the dimensions of positive and negative battery contact ports, terminals, and contact points to ensure that they meet standards and are properly connected to the battery management system (BMS) or other connecting devices.

Improper port sizes can result in poor contact, heat, or failure to function properly, so it is important to ensure that the port is connected to the battery body in the correct position and size.

Battery assembly compatibility

Ensure that each cell is the correct size and shape to be assembled into the battery module or system.

Measure the adaptability of battery cells in module assembly to avoid assembly problems caused by dimensional errors, such as loose and poor contact.

Tolerance range control

Set and control the tolerance range of the battery size to ensure that the size error of each battery does not exceed the set standard during the production process.

Through strict tolerance control, it is possible to ensure the consistency of the battery in the production batch and reduce the rate of product unqualified due to size problems.

low-speed car batteries

Low-speed vehicle battery is a kind of battery designed for low-speed electric vehicles, which has the characteristics of clean, environmental protection, high efficiency and economy, and is widely used in electric golf carts, low-speed electric vehicles (LSV), mobile vendors, campus transportation, cargo trucks and so on

Extended reading

Product packaging and delivery

Product packaging and delivery The packaging and delivery of battery...

Product information expansion

Product information expansion Understanding low-speed vehicle battery product information is...

Product composition

Low-speed lithium battery product composition Understanding the product composition of...

THE ESSC Brand promise

Global supply

Our products sell well all over the world, covering many countries and regions, through the global logistics network, to provide customers with convenient purchasing experience.

Rigorous quality

We adhere to the highest quality control standards to ensure every product meets industry regulations and customer expectations, earning trust through consistent excellence.

Excellent service

With a customer-centric approach, we provide prompt responses, professional support, and personalized services, aiming to deliver the best user experience and long-term value.