How to test the static voltage of a single battery...

Single cell short circuit test

In the performance evaluation and safety verification of battery, short circuit test is a key experiment. By short circuit testing of a single battery, its performance in extreme conditions can be found, the safety and reliability of the battery can be evaluated, and dangerous accidents can be prevented in practical applications. In this paper, the operation steps, required instruments and related precautions of single cell short circuit test will be introduced in detail.

the purpose of short circuit test

Assessing safety: Short circuit testing can simulate the reaction of the battery under unexpected conditions, such as wire contact or battery damage, and evaluate the resistance of the battery to short circuit.

Test thermal stability: analyze the heat generated by the battery under short-circuit conditions, understand its temperature rise characteristics, and avoid security risks caused by overheating.

Verify protection mechanisms: Many modern batteries are equipped with overcurrent protection and temperature protection circuits, and short-circuit testing can verify that these protection mechanisms are working properly.

Understanding the battery behavior: The response of the battery under transient load can be evaluated by short circuit testing, including voltage changes and discharge characteristics, among others.

the basic principle of short circuit test

The short-circuit test is mainly carried out by directly connecting a low-impedance load at the output of the battery, causing the current to reach its limit. In this process, the electrochemical reactions inside the battery will be excited, which may lead to the increase of battery temperature and voltage change, etc. Finally, these reactions will be combined with the structure and material of the battery to evaluate the safety and performance of the battery.

short circuit test operation steps

Preparation

Ensure that the testing environment meets safety standards and avoids the presence of high temperature, high humidity and flammable materials.

Select appropriate test equipment and tools to ensure the safety of operators and equipment.

Select the test battery

Select the single cell to be tested and check the appearance of the battery to ensure that there is no obvious physical damage.

Connection load

Use suitable short-circuit test equipment (such as short-circuit test fixture) to connect the positive and negative electrodes of the battery. When connected, ensure that hands and tools are kept dry to avoid the risk of electric shock.

Ensure that the test equipment can withstand high current and prevent battery damage due to excessive current.

Short circuit test

Start the short circuit test and record the current, temperature, voltage and other related data when the battery is short circuit.

Use appropriate protective devices (e.g. fuses, overcurrent protection) to prevent accidents.

Observe the test results

The temperature rise, appearance changes and possible abnormal conditions of the battery were monitored in real time during the test.

The test ends by safely disconnecting.

Analysis and Evaluation

The data recorded in the test were collated and analyzed to summarize the results of the short-circuit test and form a report.

Required instruments and equipment

Short circuit test equipment

Professional short circuit test instruments can provide stable short circuit current and excellent temperature monitoring capabilities. These devices are often equipped with overcurrent protection to ensure the safety of equipment and personnel during testing.

Current detector

It is used to monitor the current change in the case of short circuit in real time, so as to analyze the short circuit response characteristics of the battery.

Temperature monitor

Temperature sensors or infrared thermometers are used to monitor changes in the temperature of the battery during short-circuit testing, to ensure safety and to assess thermal stability.

Data logger

Portable data loggers can record various parameters of battery short-circuit tests, such as current, voltage, and temperature, for subsequent analysis.

Insulated gloves and goggles

When performing short-circuit tests, operators should wear personal protective equipment to ensure their own safety.

Precautions

Follow safety procedures:

Ensure that the operator is aware of the risk of short circuit testing, especially the safety procedures for operating in high current environments.

Avoid direct contact with:

During testing, avoid direct hand contact with the positive and negative electrodes of the battery to reduce the risk of accidental short circuit.

Appropriate environment:

The short circuit test should be carried out in a well-ventilated environment away from flammable substances to avoid fire caused by excessive heat.

Continuous monitoring:

During the test process, the battery temperature and current should be continuously monitored, and timely measures should be taken to ensure safety.

Disposal of abandonment:

If the battery generated after the test needs to be discarded, it shall be treated in strict accordance with the relevant environmental protection regulations to avoid pollution to the environment.

Conclusion

The short circuit test of single battery is an important part to evaluate its safety and performance. Through the operation steps of the system and professional instruments and equipment, the short circuit behavior of the battery can be effectively understood, which provides a scientific basis for the safe use of the battery. Safety should always be the top priority when performing short circuit testing, and ensuring the safety of operators and test equipment is the key to the success of the test. Regular short circuit testing and other safety assessments are important means to improve the safety of battery applications.

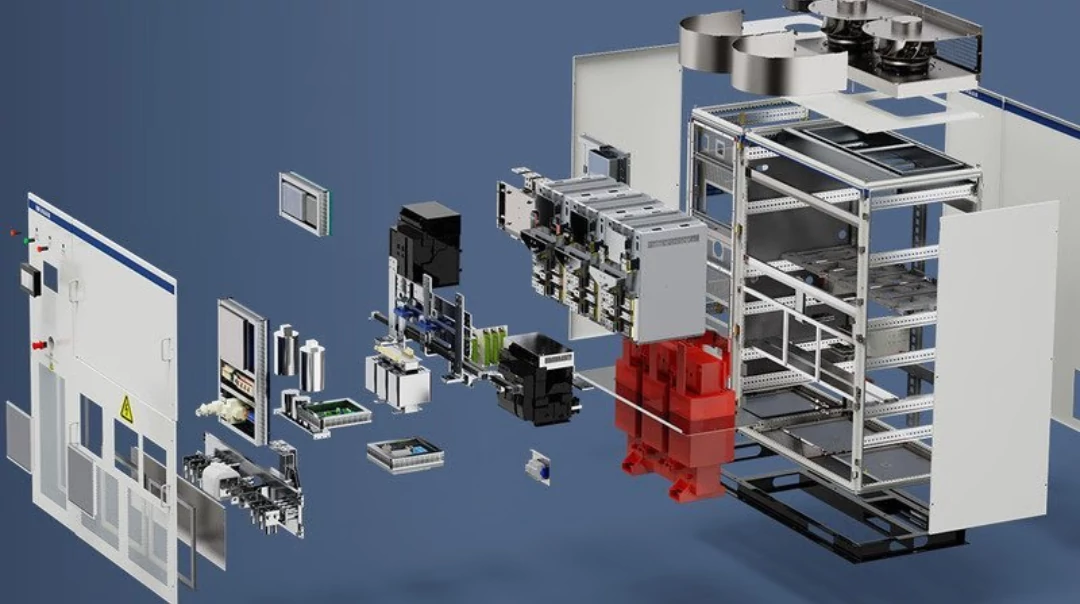

Home energy storage product series

A lithium battery pack for home energy storage systems, which is compatible with solar panels and the sun The inverter can work together with the power grid to power household appliances, and it can also be used as a For off grid systems.

THE ESSC Brand promise

Global supply

Our products sell well all over the world, covering many countries and regions, through the global logistics network, to provide customers with convenient purchasing experience.

Rigorous quality

We adhere to the highest quality control standards to ensure every product meets industry regulations and customer expectations, earning trust through consistent excellence.

Excellent service

With a customer-centric approach, we provide prompt responses, professional support, and personalized services, aiming to deliver the best user experience and long-term value.