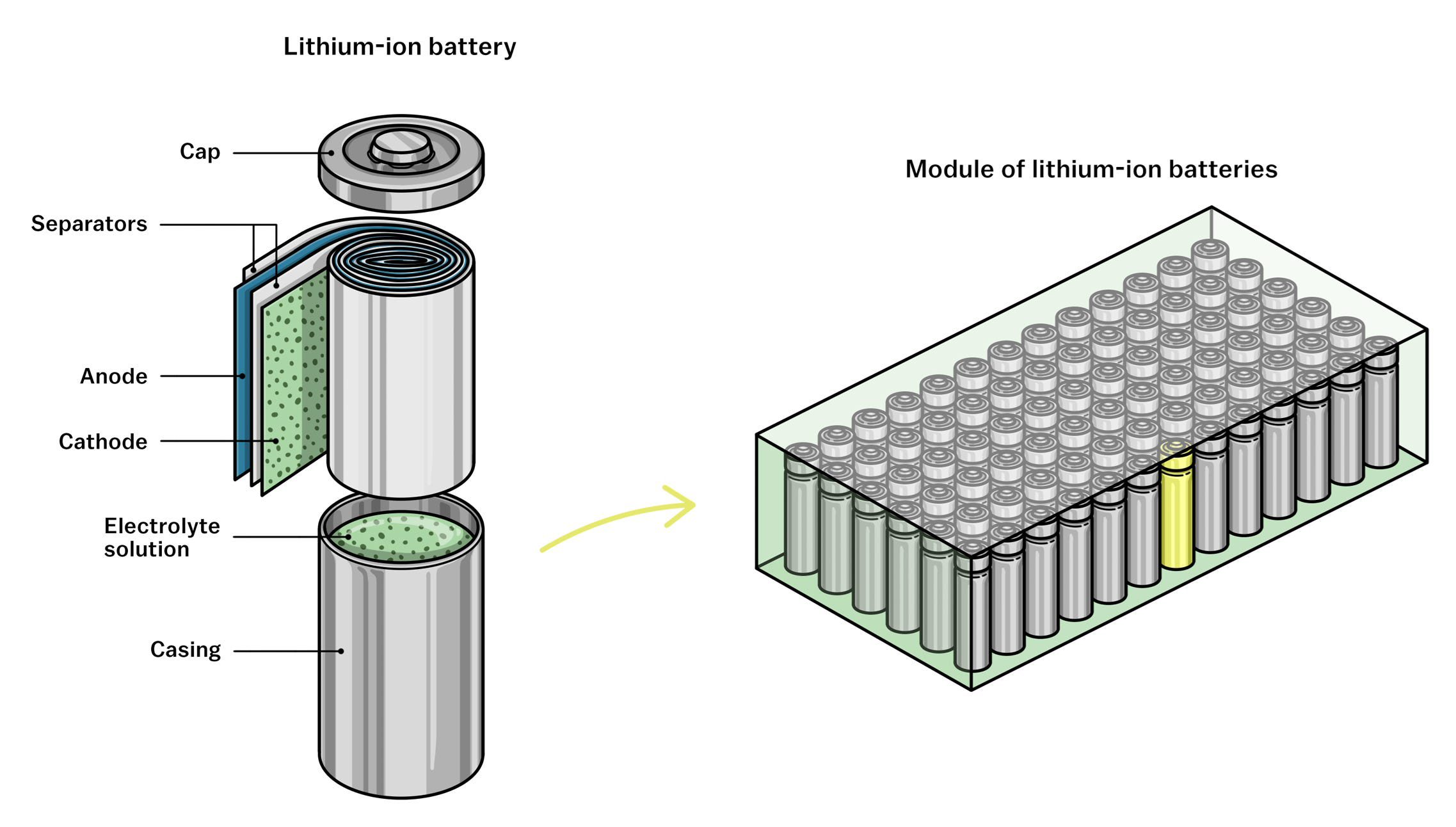

Components of a battery cell Battery cell is the basic...

Single cell internal resistance test

With the continuous development of battery technology, more and more attention has been paid to the performance and reliability of batteries. As one of the important parameters of battery, internal resistance not only affects its charging efficiency and discharge performance, but also directly relates to the life and safety of battery. Therefore, it is of great practical significance to test the internal resistance of the single battery. This article will introduce the operation steps of the single cell internal resistance test and the required instruments and equipment to help readers better understand this process.

why test the internal resistance of the single battery?

Judging battery status: Internal resistance is an important indicator of battery health status. The increase of internal resistance will lead to the increase of energy loss of the battery, which will affect the efficiency and life of the battery.

Optimal use: understanding the internal resistance of the battery can help users use the battery reasonably and reduce the risk.

Fault diagnosis: through regular testing of internal resistance, you can find the potential fault problems of the battery in time, and take corresponding maintenance measures to ensure the safe operation of the battery.

the basic principle of internal resistance test

The internal resistance of a single cell can be calculated by applying a known current and measuring the voltage drop. The internal resistance (R) can be expressed by Ohm's law as follows.

[ R = \frac{\Delta V}{I} ]

Among them:

(\Delta V) is the voltage change caused by the applied current;

(I) is the magnitude of the applied current.

the operation steps of internal resistance test

Preparation

Confirm that the temperature and humidity of the test environment meet the standards, so as not to affect the test results.

Select the appropriate test instrument (such as internal resistance tester).

Connect the battery

Connect the positive and negative electrodes of the internal resistance tester to the positive and negative electrodes of the battery to ensure good connection and no short circuit phenomenon.

Select the test parameters

The appropriate test current is selected according to the battery type. For lithium batteries, the test current of 100mA~1A is generally selected; A similar range can be chosen for lead-acid batteries.

Test it

Start the internal resistance tester and apply the set current. The instrument automatically measures the voltage drop of the battery and calculates the internal resistance.

Log the data

Record the test results, including the internal impedance value of the battery and the environmental parameters (temperature, humidity, etc.) during the test.

Analysis and Evaluation

According to the internal resistance value obtained from the test, it is compared with the standard internal resistance value of the battery to evaluate the health state of the battery.

Repeat the test

Multiple tests can be performed as required to ensure the accuracy of the results.

Required instruments and equipment

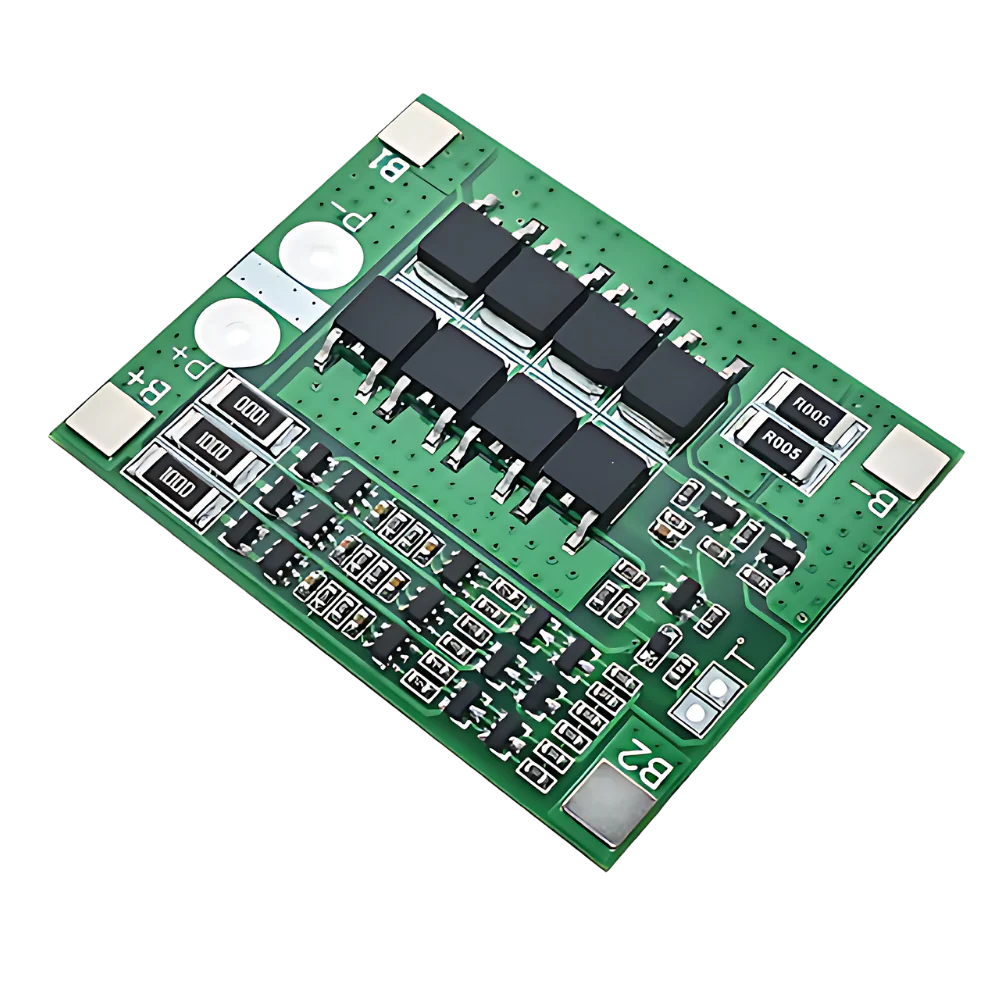

Internal resistance tester

This is the main device for testing the internal resistance of a single battery. The internal resistance tester usually has a high-precision current source and voltage measurement circuit, which can quickly and accurately calculate the internal resistance value.

Multimeter (optional)

In the absence of an internal resistance tester, it is possible to use a multimeter to measure static voltage and current and calculate the internal resistance by hand, but this method is relatively inefficient and less accurate.

Battery charger (optional)

Before the test, the battery can be charged with the battery charger to ensure that the SOC (State of Charge) of the battery is at the appropriate level and improve the test accuracy.

Thermometer

Temperature has a certain impact on the internal resistance test of the battery, so it is necessary to record the ambient temperature. You can use a multimeter with a temperature measuring probe, or a standalone thermometer.

Data logging equipment

Use a computer or notebook to record and store the test data to facilitate subsequent data analysis and comparison.

Precautions

Avoid short circuit: Ensure that the connection of the tester is stable and reliable to avoid short circuit in the test process.

Appropriate test current selection: Different types of batteries apply different test currents, avoid choosing too large or too small currents, so as not to cause battery damage or inaccurate test data.

Effect of temperature:

In different temperature environments, the internal resistance performance of the battery will be different, try to test at room temperature.

Multiple tests:

Multiple tests can be performed to ensure the accuracy of the data, especially when determining battery health.

Safety first:

Always follow the safety guidelines for battery testing and wear appropriate personal protective equipment to ensure the safety of the testing environment.

Conclusion

The internal resistance test of single battery is an important process to evaluate the performance and health status of battery. Through the correct selection of test equipment, reasonable operation and attention to safety measures, the accurate data of battery internal resistance can be effectively obtained, which provides an important basis for battery management and maintenance. As battery technology advances and application demands increase, internal resistance testing will continue to play its important role. In order to ensure the efficient and safe use of batteries, regular internal resistance testing is indispensable.

Home energy storage product series

A lithium battery pack for home energy storage systems, which is compatible with solar panels and the sun The inverter can work together with the power grid to power household appliances, and it can also be used as a For off grid systems.

Extended reading

THE ESSC Brand promise

Global supply

Our products sell well all over the world, covering many countries and regions, through the global logistics network, to provide customers with convenient purchasing experience.

Rigorous quality

We adhere to the highest quality control standards to ensure every product meets industry regulations and customer expectations, earning trust through consistent excellence.

Excellent service

With a customer-centric approach, we provide prompt responses, professional support, and personalized services, aiming to deliver the best user experience and long-term value.