Depth of Discharge (DOD) of battery pack In the field...

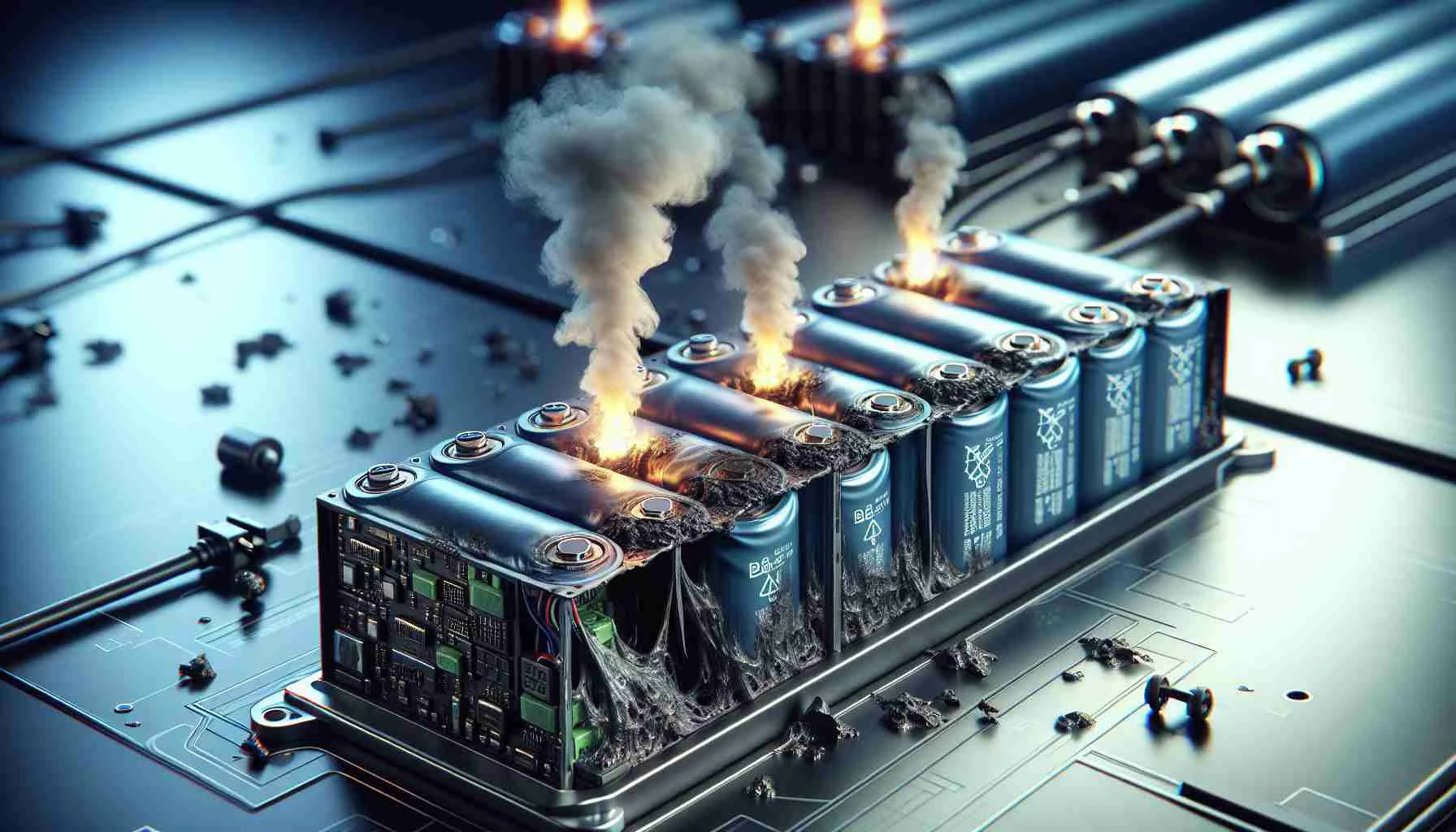

Single battery overcharge test

With the continuous progress of battery technology, efficient and safe charging technology has become more and more important. The overcharge test is one of the important experiments to evaluate the possible problems of the battery during charging. Through the overcharge test of single battery, potential safety hazards can be found in time to ensure the safety and life of the battery. This article will introduce the purpose of single battery overcharge test, operation steps, required instruments, and matters needing attention.

Purpose of overcharge test

Safety assessment: Overcharge may cause battery heating, expansion, leakage and even fire. Through the overcharge test, the safety performance of the battery under overcharge can be evaluated and potential faults and risks can be found.

Performance analysis: Understand the performance changes of the battery in the overcharge state, especially the key parameters of the battery such as voltage, capacity and cycle life.

Verify protection mechanisms: Modern batteries are usually equipped with protection circuitry to prevent overcharging. Overcharge testing can verify the effectiveness of these protection mechanisms.

Optimize the charging strategy: Through the overcharge test, the reaction of the battery in the charging process is analyzed, and the improvement of the charging algorithm is driven to improve the charging efficiency and safety of the battery.

the basic principle of overcharge test

The basic principle of overcharge testing is to connect a single battery to a charging device and deliberately exceed its rated voltage or charging time during the charging process. At this time, the electrochemical reaction inside the battery will intensify, which may lead to temperature increase, gas release, and even structural damage, thus affecting the life and safety of the battery.

Operation steps of overcharge test

Preparation

Ensure that the testing laboratory environment is dry and well ventilated to avoid the presence of high temperatures and flammable materials.

Select the appropriate battery model to ensure that the battery has been counted and checked before testing, and the appearance is good.

Equipment selection and preparation

Prepare charging equipment, such as a charger with adjustable voltage and current, and ensure that it fits the specifications of the battery to be tested.

Prepare monitoring equipment for real-time monitoring of the voltage, temperature and charging current of the battery.

Connect the battery

Use the appropriate cable to connect the battery to the charger to ensure reliable connection and good insulation.

Avoid short circuit in the connection process to ensure the safety of the operator.

Set charging parameters

The voltage and current of the charger were set according to the rated voltage and charging specifications of the battery, and these initial parameters were recorded.

Set the target voltage for overcharge, usually 1.1-1.2 times the rated voltage.

Perform an overcharge test

Start the charger, start charging, and monitor the voltage, temperature and charging current of the battery in real time.

After the battery reaches the set overcharge voltage, the battery is continuously charged and the changes of various performance indicators of the battery are observed.

Data recording and observation

During the whole test process, the battery voltage, temperature, charging current and other data were recorded. Pay special attention to any abnormal changes, such as swelling, leakage, smoke, etc.

Observe the state changes of the battery, and record whether there are dangerous situations such as burst and fire.

End the test

Once the test goal is reached, power is quickly and safely disconnected by appropriate means. After the battery is allowed to cool to room temperature, the appearance and performance of the battery are further checked, especially for the presence of structural damage.

Data analysis and report

Collate and analyze the data collected in the test process, write a detailed test report, and evaluate the overcharge performance and safety of the battery.

Required instruments and equipment

Adjustable power charger

Used to provide a variable current and voltage environment, ensuring that overcharge conditions can be set and achieved.

Current monitor

Accurate measurement of the current in the charging process ensures the stability of the charging process.

Voltmeter

The voltage change of the battery is monitored in real time to ensure that it is within the set range.

Temperature sensor

It is used to monitor the temperature change of the battery in the process of charging to ensure that it is within the safe range.

Data logger

It is used to record the data during the test in real time, which is convenient for subsequent analysis.

Safety protection equipment

Including insulated gloves, safety goggles, etc., to ensure the safety of operators.

Precautions

Safety Regulations:Follow laboratory safety procedures and operation specifications to ensure the safety of personnel and equipment during operation.

Monitoring frequency:

During the charging process, the battery voltage and temperature should be monitored regularly to detect abnormal conditions in time.

State of charge:

Ensure that the charging equipment is calibrated before testing, and the output of the charging power supply should be stable and reliable.

Environmental Safety:

Ensure that the testing environment is free from flammable materials and equipped with appropriate fire extinguishing equipment.

Disposal of waste:

If the battery is found to be damaged or leaking after testing, it is necessary to properly dispose of batteries and other waste materials in accordance with local environmental regulations.

Conclusion

The overcharge test of single battery is an important experiment to ensure the safety and performance of battery. Through the operation steps of the system and professional instruments and equipment, the overcharge behavior of the battery can be effectively evaluated, which provides data support for improving the charging strategy and improving the battery safety. Always putting safety first and strictly following the test procedures is the key to overcharge testing. It is an important responsibility of every battery engineer to ensure the stability and safety of the battery in practical applications through safe and reliable testing methods.

Home energy storage product series

A lithium battery pack for home energy storage systems, which is compatible with solar panels and the sun The inverter can work together with the power grid to power household appliances, and it can also be used as a For off grid systems.

Extended reading

Operating temperature range of the battery pack

Operating temperature range of the battery pack Battery packs play...

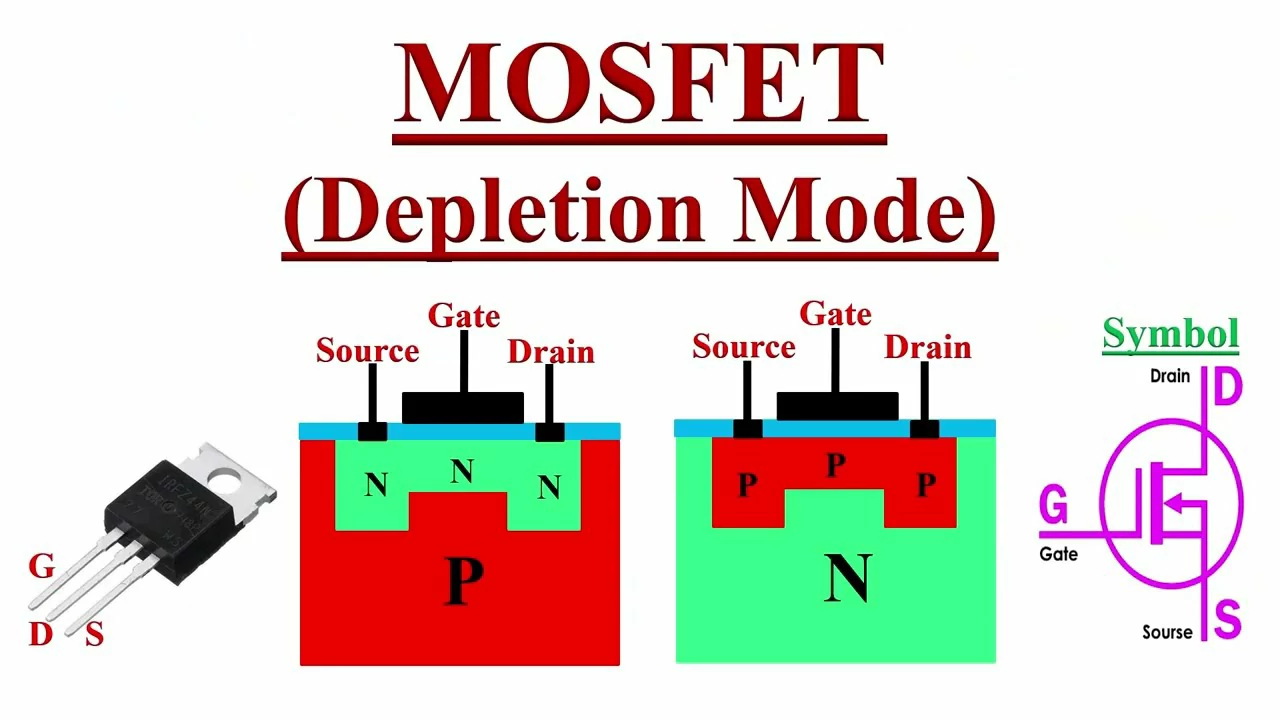

Introduction to depletion MOSFETs

Introduction to depletion MOSFETs what is depletion MOSFET The Depletion...

THE ESSC Brand promise

Global supply

Our products sell well all over the world, covering many countries and regions, through the global logistics network, to provide customers with convenient purchasing experience.

Rigorous quality

We adhere to the highest quality control standards to ensure every product meets industry regulations and customer expectations, earning trust through consistent excellence.

Excellent service

With a customer-centric approach, we provide prompt responses, professional support, and personalized services, aiming to deliver the best user experience and long-term value.