Product testing Product testing is a key link to ensure...

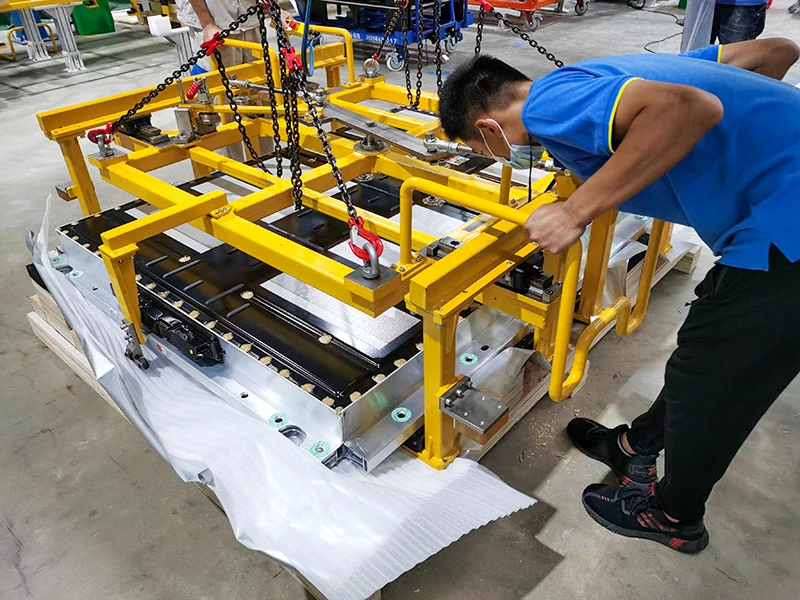

Shock-proof packing

Shock-proof packaging is a protective measure designed to prevent physical damage such as external vibration, shock or drop during the transportation, storage and use of batteries. The internal structure of the battery is precise, and the external packaging material is susceptible to shock. If it is not effectively shockproof, it may cause problems such as shell deformation, internal short circuit, and battery cell damage. Through the shock-proof packaging design, the battery can be protected from the impact of mechanical shocks, thereby improving the safety of its transport and use.

Shock-proof packing

Shock-proof packaging is an important part of battery safety design, which can effectively prevent structural damage or performance problems caused by vibration or shock. Through the use of cushioning materials, compartmental design and rigorous dynamic testing, shock-proof packaging can significantly improve the safety, reliability and transport adaptability of batteries, guaranteeing their stability in a variety of environments.

Design essentials

Use materials with good shock-absorbing properties (such as foam, bubble film, etc.) to wrap the battery to reduce the direct impact of external forces on the battery.

In the packaging through the partition or independent slot design, to avoid direct contact and collision between batteries, increase the protective effect.

The packaging shell must be strong enough to prevent the battery from being damaged due to external pressure or collision.

After the packaging design is completed, simulated vibration, drop and shock tests are carried out to ensure that the packaging can meet the shock resistance requirements of the transport and use environment.

low-speed car batteries

Low-speed vehicle battery is a kind of battery designed for low-speed electric vehicles, which has the characteristics of clean, environmental protection, high efficiency and economy, and is widely used in electric golf carts, low-speed electric vehicles (LSV), mobile vendors, campus transportation, cargo trucks and so on

Extended reading

Product packaging and delivery

Product packaging and delivery The packaging and delivery of battery...

Product information expansion

Product information expansion Understanding low-speed vehicle battery product information is...

Product composition

Low-speed lithium battery product composition Understanding the product composition of...

THE ESSC Brand promise

Global supply

Our products sell well all over the world, covering many countries and regions, through the global logistics network, to provide customers with convenient purchasing experience.

Rigorous quality

We adhere to the highest quality control standards to ensure every product meets industry regulations and customer expectations, earning trust through consistent excellence.

Excellent service

With a customer-centric approach, we provide prompt responses, professional support, and personalized services, aiming to deliver the best user experience and long-term value.