Package Mylar Wrap Mylar film around the bare core and...

Shock and vibration testing of single cell batteries

With the wide popularity of electronic devices and electric vehicles, the reliability and safety of single battery have received unprecedented attention. Shock and vibration testing is an important means to evaluate the performance of the battery under abnormal mechanical stress to ensure that the battery can work safely and reliably during actual use. This article will introduce the operation process of the impact and vibration test of the single battery, the required instrument and the relevant precautions.

the purpose of shock and vibration testing

Safety assessment: simulate the battery in the process of transportation and use of accidents, such as falling, collision, etc., to observe whether the battery leakage, short circuit, fire or explosion and other safety hazards.

Performance stability: Test the electrical performance of the battery under vibration and impact conditions to evaluate its reliability and stability in long-term use.

Compliance: Ensure that batteries comply with relevant safety and performance standards such as UN 38.3, IEC 62133, etc., to support market access and compliance.

Design optimization: The test results are used to optimize the battery design and improve its shock and vibration resistance.

the basic principle of impact and vibration testing

Impact test: Impact test applies instantaneous mechanical force to simulate the strong impact that the battery may experience in real applications. Such testing can help identify potential failure modes of the battery under impact conditions.

Vibration test: Vibration test applies continuous dynamic stress at a certain frequency and amplitude to simulate the various vibration environments experienced by the battery during transportation or operation. This test is able to assess the response of the battery at different frequencies and whether material fatigue or interface failure will occur.

Operation steps of shock and vibration test

Preparation

Ensure that the testing environment complies with safety standards and is equipped with necessary safety measures.

Select the single cell to be tested and check the appearance of the battery to ensure that there is no obvious crack or damage.

Equipment selection and preparation

Select the appropriate vibration test bench (such as electric vibration table) and impact testing machine (such as impact testing machine).

Prepare monitoring equipment, including temperature sensors, voltmeters and data loggers, etc., for real-time recording of test data.

Connect the battery

The battery to be tested is fixed on the vibration test bench or impact test machine to ensure that the connection is reliable and the external force can be effectively felt.

Set the test parameters

Set the impact energy, type (such as free fall method, impact hammer, etc.), frequency and duration of impact test according to relevant standards.

For vibration testing, parameters such as vibration frequency, amplitude and test time were set.

Test it

Start test equipment for impact or vibration test.

During the test process, the indicators of the battery were monitored in real time, and attention was paid to observe whether abnormal phenomena occurred, such as temperature rise and voltage change.

Log the data

Data such as temperature, voltage, frequency and impact energy during the test were regularly recorded to ensure the integrity of all data.

If any safety concerns are observed, stop testing immediately.

End the test

When the test is complete, stop the device and carefully remove the battery.

Check the appearance and function of the battery to observe whether there is damage, swelling, leakage and other phenomena.

Data analysis and report

The data recorded during the experiment were sorted out and the necessary data analysis was carried out.

Write a test report summarizing the battery's performance in shock and vibration tests and assessing its safety and reliability.

Required instruments and equipment

Vibration test bench

It is used to simulate the vibration conditions that the battery may experience during transportation and work, and has the ability to adjust the frequency and amplitude.

Impact testing machine

It can simulate the impact of the battery, usually using impact hammer or free fall way to apply force.

Data acquisition system

It is used to record and analyze the temperature, voltage and other related parameters of the battery in real time during the test.

Temperature sensor

Monitor the battery temperature changes in real time to ensure that the safety threshold is not exceeded.

Safety protection facilities

Protective cover, insulated gloves and goggles are included to ensure the safety of operators during testing.

Precautions

Safety first:

During the test, the operator must wear appropriate safety protective equipment to prevent potential safety risks.

Equipment calibration:

Ensure that all test equipment and monitoring instruments are calibrated and in good working condition before testing.

Stable test environment:

The test environment should be stable to avoid external interference factors affecting the test results.

Waste Management:

After the test, the damaged or leaked battery should be properly disposed of, and the relevant environmental protection and safety regulations should be followed.

Follow the standards:

Ensure that the testing process conforms to international and safety standards and corresponding industry norms to ensure the validity and reliability of the test results.

Conclusion

The impact and vibration test of single battery is an important part to ensure its safety under actual working conditions. Through scientific and rigorous testing programs and professional equipment, the performance of batteries in extreme environments can be effectively evaluated, and the safety of related products can be guaranteed. At the same time, understanding the testing process and precautions is also the key to ensure the smooth progress of testing. In this way, we can further improve the design and manufacturing standards of batteries to ensure their safety and reliability in various applications.

Home energy storage product series

A lithium battery pack for home energy storage systems, which is compatible with solar panels and the sun The inverter can work together with the power grid to power household appliances, and it can also be used as a For off grid systems.

Extended reading

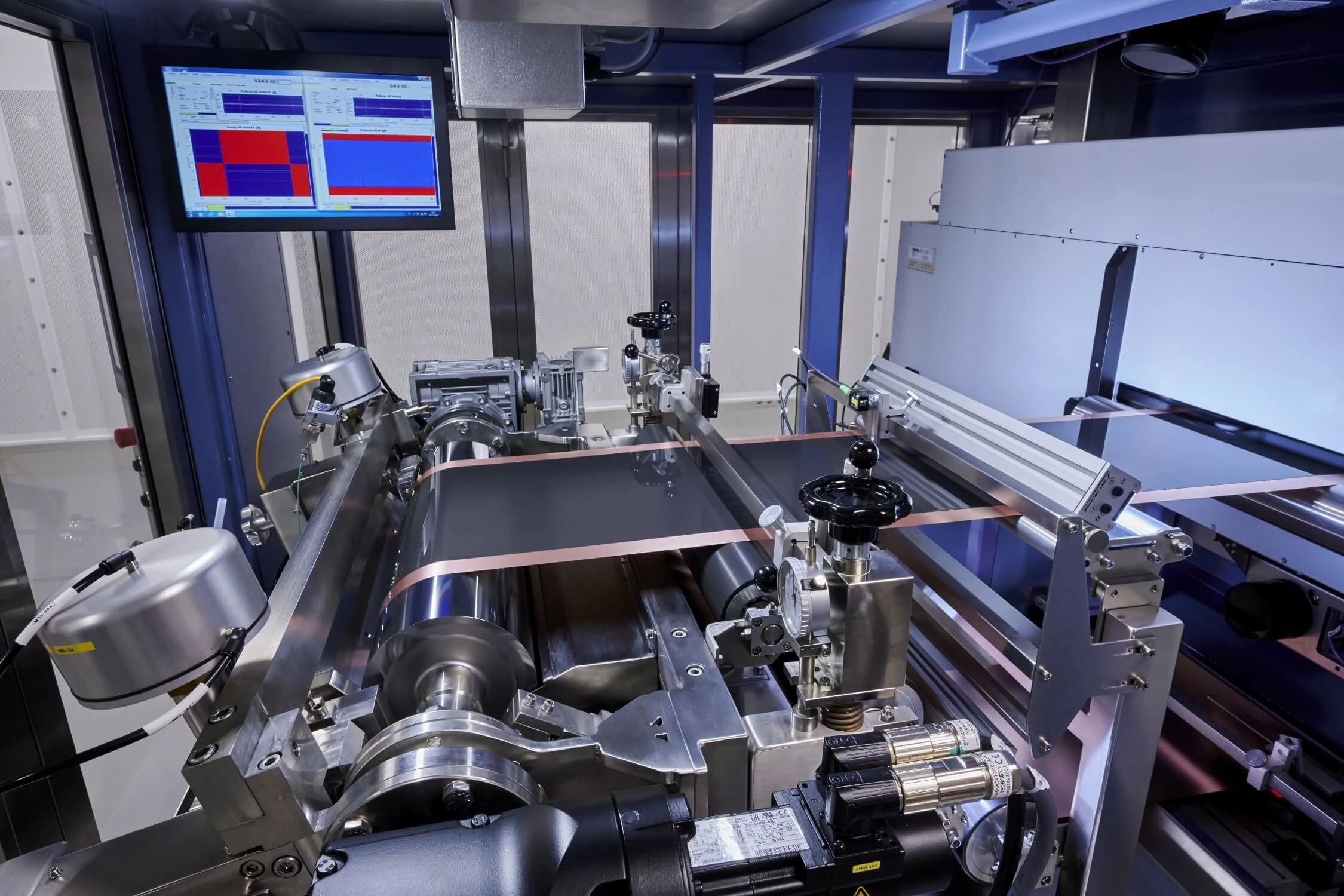

The dry mixing technology of electrode

The dry mixing technology of electrode Dry mixing process is...

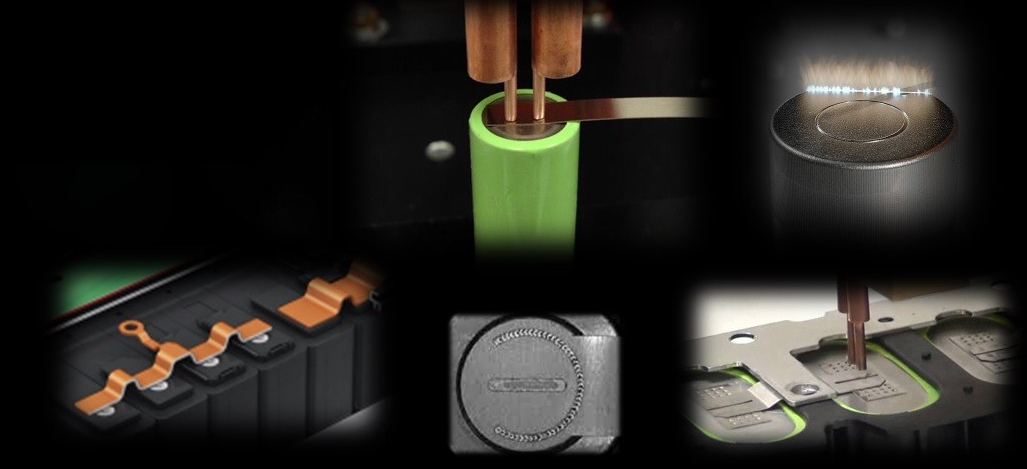

Product testing of welding terminals

Product testing of welding terminals The quality of the soldered...

THE ESSC Brand promise

Global supply

Our products sell well all over the world, covering many countries and regions, through the global logistics network, to provide customers with convenient purchasing experience.

Rigorous quality

We adhere to the highest quality control standards to ensure every product meets industry regulations and customer expectations, earning trust through consistent excellence.

Excellent service

With a customer-centric approach, we provide prompt responses, professional support, and personalized services, aiming to deliver the best user experience and long-term value.