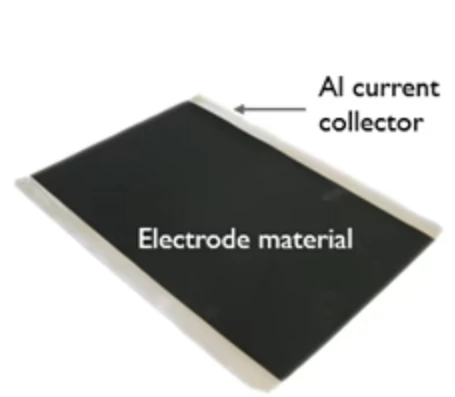

How can composite materials improve performance in battery electrode collector?...

Safety valve and pressure release device of EPS battery unit

Battery cells, especially EPS (encapsulated power system) batteries, produce gas and increase internal pressure during charging and discharging, so it is essential to have an effective safety valve and pressure relief device. These devices can automatically release excess gas when the pressure is too high, ensuring the safety and stability of the battery.

main content

Stainless steel is commonly used in the manufacture of safety valves and pressure relief devices because it has good corrosion resistance and strength. The stainless steel safety valve can break when the internal pressure of the battery rises to a certain extent, releasing the pressure and preventing the battery from exploding. For example, some battery manufacturers use laser welding firmly two aluminum metal sheets, when the internal pressure rises to a certain value, the aluminum sheet breaks from the designed groove position.

Aluminum alloys are used in battery safety valves and pressure relief devices because of their light weight and good workability. The position of the safety valve is generally located in the center of the battery cover plate, and the battery cover plate and the explosion plate can be connected by two methods of integrated processing or split processing. In split processing, the explosion-proof sheet is usually formed by stamping 1050 aluminum alloy sheet, and then laser welding is connected to the cover plate.

Polypropylene (PP) is used in safety valves and pressure relief devices for batteries because of its light weight, chemical resistance and economy. PP materials can be used to make explosion-proof discs, which are parts that break to release pressure when the internal pressure exceeds a certain value.

Fluoroplastics, such as polytetrafluoroethylene (PTFE), are used as seals in safety valves and pressure relief devices because of their excellent chemical resistance and low coefficient of friction. These materials maintain performance in extreme temperature and chemical environments and are suitable for battery applications that require high corrosion resistance.

Superalloy springs are used in safety valves and pressure relief devices to ensure that the valve responds correctly when the pressure inside the battery changes. These springs maintain their performance in high temperature environments, ensuring that the safety valve can be opened and closed in time when needed.

CONCLUSION

In summary, the safety valve and pressure release device of the EPS battery cell are manufactured with a variety of materials to ensure that the pressure can be effectively released when the internal pressure of the battery is too high, protecting the battery and user safety. Each material has its own unique properties and application scenarios, and manufacturers will choose the appropriate material according to the specific requirements of the battery and the application environment.

EPS BATTERY SERIES

The centralized power supply for fire emergency lighting is a kind of backup power supply equipment, which provides power guarantee for emergency lighting equipment to ensure that the on-site lighting equipment can operate normally in emergency situations such as fire. Provide a long-term backup power supply to meet the needs of the emergency lighting system.

Extended reading

This section describes the battery in the EPS battery unit

This section describes the battery in the EPS battery unit...

Materials for safety valves and pressure relief devices – Polypropylene (PP)

Materials for safety valves and pressure relief devices – Polypropylene...

Materials for safety valves and pressure relief devices – stainless steel

Materials for safety valves and pressure relief devices – stainless...

Detailed explanation of EPS AC charging interface

Detailed explanation of EPS AC charging interface In the emergency...

Control system analysis – control algorithm

Control system analysis – control algorithm The control algorithm is...

THE ESSC Brand promise

Global supply

Our products sell well all over the world, covering many countries and regions, through the global logistics network, to provide customers with convenient purchasing experience.

Rigorous quality

We adhere to the highest quality control standards to ensure every product meets industry regulations and customer expectations, earning trust through consistent excellence.

Excellent service

With a customer-centric approach, we provide prompt responses, professional support, and personalized services, aiming to deliver the best user experience and long-term value.