Charging and discharging efficiency test of single battery The charging...

Roll pressure

After coating and drying, the stripping high strength of live matter and fluid collecting foil is very low, and it is necessary to roll it to enhance the bonding strength of live matter and foil, to prevent it from peeling off in the process of electrolyte immersion and battery use. The roll ensures that the surface of the pole piece is smooth and flat, to prevent the burr on the coating surface from puncting the diaphragm and causing short circuit, and to compress the volume of the battery core. Improve the energy density of the battery core, reduce the porosity between the living matter, conductive agent and binder in the electrode chip, reduce the resistance of the battery and improve the performance of the battery.

Specific process

Deviation Control: ensures that the material stays in the correct position during the roller pressing process.

Tension Control: The tension of the material is controlled to ensure the stability of the rolling process.

Automatic Unwinding from Tower: Automatically releases material from the tower.

Manual Tape Joining: To manually join two ends of a material.

Dust and Iron Removal: Remove dust and iron impurities from materials.

Wrinkling Removal: Removing wrinkles from a material.

Roller: Hydraulic: Operate using a hydraulic system.

Wrinkling Removal: Removing wrinkles from a material.

Cooling/Oven: The material is baked.

Cooling: Cooling the material.

Laser Thickness Measurement: The use of laser technology to measure the thickness of materials.

Tape Joining

Brick tower automatic Rewinding

Deviation Control: Carry out deviation control again to ensure the quality of the material after winding.

Tension Control: Controls the tension of the material again.

The operation method of rolling and cutting

Deviation Control: ensures that the material remains in the correct position during processing.

Tension Control: Controls the tension of the material to ensure stability during processing.

Automatic Unwinding from Tower: Automatically releases material from the tower.

Manual Tape Joining: To manually join two ends of a material.

Dust and Iron Removal: Remove dust and iron impurities from materials.

Wrinkling Removal: Removing wrinkles from a material.

Roll Pressing: The material is compacted by a roller press.

Hydraulic: To operate using a hydraulic system.

Wrinkling Removal: Removing wrinkles from a material.

Laser Thickness Measurement: The use of laser technology to measure the thickness of materials.

Manual Tape Joining: To manually join two ends of a material.

Process Deviation Correction: The correction of deviation in the machining process.

Slitting: Cutting a material to the desired width.

CCD Measurement: Measurement of size or quality using a CCD camera.

Dust and Iron Removal: Remove dust and iron impurities from materials.

Manual Tape Joining: Performing manual tape joining again.

Manual Rewinding on Single Shaft: The material is rolled up manually.

Tension Control: Finally, the tension of the material is controlled again.

Deviation Control: Finally, the deviation control is carried out again to ensure the quality of the material after winding.

Home energy storage product series

A lithium battery pack for home energy storage systems, which is compatible with solar panels and the sun The inverter can work together with the power grid to power household appliances, and it can also be used as a For off grid systems.

Extended reading

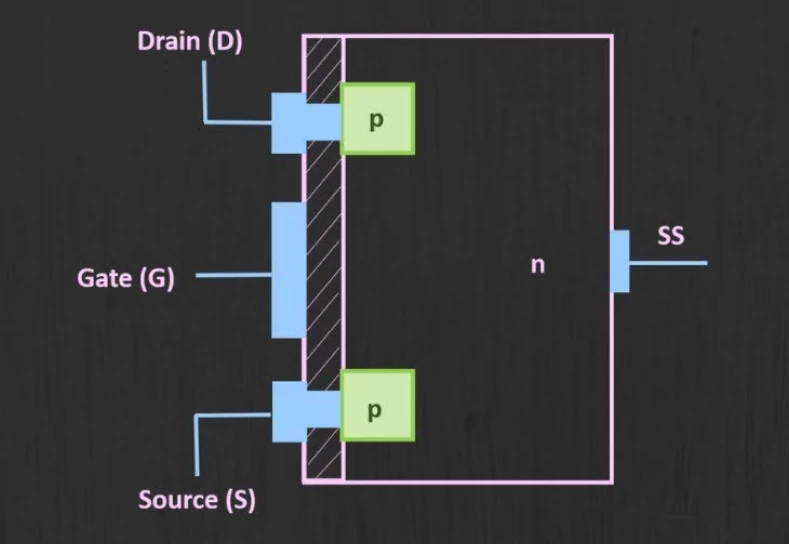

Introduction to enhanced MOSFET

Introduction to enhanced MOSFET what is an enhanced MOSFET Enhancement...

LiFePo4 home energy storage battery

A highly integrated backup power solution for solar home energy...

THE ESSC Brand promise

Global supply

Our products sell well all over the world, covering many countries and regions, through the global logistics network, to provide customers with convenient purchasing experience.

Rigorous quality

We adhere to the highest quality control standards to ensure every product meets industry regulations and customer expectations, earning trust through consistent excellence.

Excellent service

With a customer-centric approach, we provide prompt responses, professional support, and personalized services, aiming to deliver the best user experience and long-term value.