Product testing Product testing is a key link to ensure...

Roll and slice

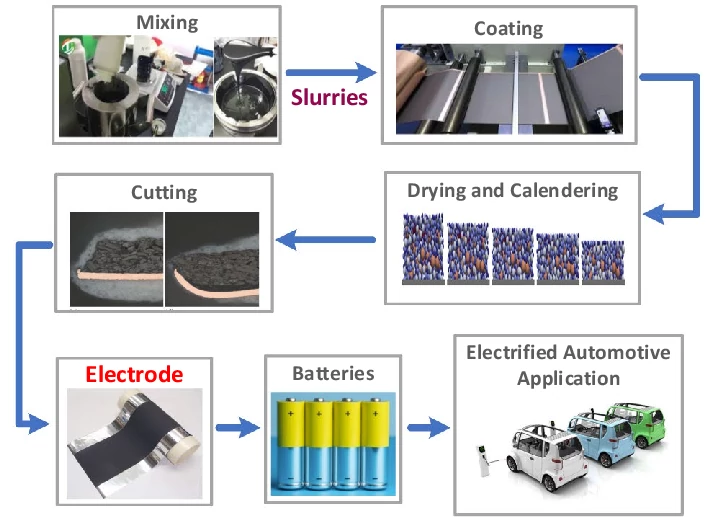

Rolling and slicing is an important step in the battery electrode manufacturing process, which is mainly used to adjust the thickness, density and shape of the electrode to ensure the performance of the electrode and the consistency of production. Rolling adjusts the thickness and density of the electrodes by mechanical pressure, and slicing cuts the rolled electrodes to a size suitable for assembly.

Roll and slice

Rolling and slicing is the key step in the manufacture of battery electrode. The thickness and density of electrode are adjusted by rolling to ensure the capacity and electrochemical performance of battery. Slicing ensures standardisation and accuracy of electrode size, facilitating subsequent assembly. Precise control of the rolling and slicing process is fundamental to ensuring high performance and consistency of the battery.

Specific steps

Rolling process

Roller press optimizes the battery's capacity, power density and cycle stability by applying mechanical pressure to adjust the thickness and density of the electrodes. Precise control of roll pressure and speed is essential to ensure electrode uniformity and avoid material breakage.

The key to the rolling process is to adjust the density and thickness of the electrodes to ensure the high performance and stability of the battery.

Slicing process

The slicing process cuts the rolled electrode into a size suitable for assembly, ensuring consistency and efficiency during battery assembly. Precise cutting ensures standardisation of electrode sizes and avoids problems during assembly.

The slicing process ensures the accuracy of electrode size, the smooth process of battery assembly and the consistency of the battery.

Comprehensive control of rolling and slicing

The density and thickness of the electrode after rolling must meet the requirements, and the electrode damage and deformation should be avoided during slicing. The coordination of the two can ensure the consistency and performance of the battery electrode.

The effective combination of roll and slice ensures the quality, size and stability of the electrode, and improves the overall performance and production efficiency of the battery.

low-speed car batteries

Low-speed vehicle battery is a kind of battery designed for low-speed electric vehicles, which has the characteristics of clean, environmental protection, high efficiency and economy, and is widely used in electric golf carts, low-speed electric vehicles (LSV), mobile vendors, campus transportation, cargo trucks and so on

Extended reading

Product packaging and delivery

Product packaging and delivery The packaging and delivery of battery...

Product information expansion

Product information expansion Understanding low-speed vehicle battery product information is...

Product composition

Low-speed lithium battery product composition Understanding the product composition of...

THE ESSC Brand promise

Global supply

Our products sell well all over the world, covering many countries and regions, through the global logistics network, to provide customers with convenient purchasing experience.

Rigorous quality

We adhere to the highest quality control standards to ensure every product meets industry regulations and customer expectations, earning trust through consistent excellence.

Excellent service

With a customer-centric approach, we provide prompt responses, professional support, and personalized services, aiming to deliver the best user experience and long-term value.