The function of the battery pack safety valve With the...

Research and application of cathode cap sealing material

The application of the sealing material in the positive cap ensures the safe, stable and efficient operation of the battery. This paper will discuss the type and performance of the cathode cap sealing material of lithium iron phosphate monomer battery and its influence on the overall performance of the battery.

the function of the positive cap and the importance of sealing materials

The positive cap is a key component that connects the electrode with the external circuit, and the sealing performance is directly related to the safety and long-term stability of the battery. The sealing material mainly plays the role of the following aspects:

Prevent external pollution: good sealing can effectively prevent moisture, air and other external pollutants from entering the battery interior, prevent oxidation and corrosion of battery materials.

Electrolyte protection: The sealed design ensures that the electrolyte remains stable inside the positive cap to avoid degradation of battery performance due to leakage.

Enhanced structural stability: The sealing material also enhances the integrity of the battery structure, preventing damage caused by thermal expansion or mechanical stress during charging and discharging.

the type and performance of commonly used sealing materials

Polyethylene (PE)

Excellent corrosion resistance and high temperature resistance, can maintain good sealing effect in extreme environments, and is not easy to react with the internal components of the battery. However, Expensive, and in some cases less processable.

Polyurethane (PU)

Polyurethane sealing material has good flexibility, can effectively compensate for the deformation caused by temperature change and mechanical stress, and provide a good sealing effect. However, In low temperature environment, the hardness of polyurethane increases and the sealing performance may decrease.

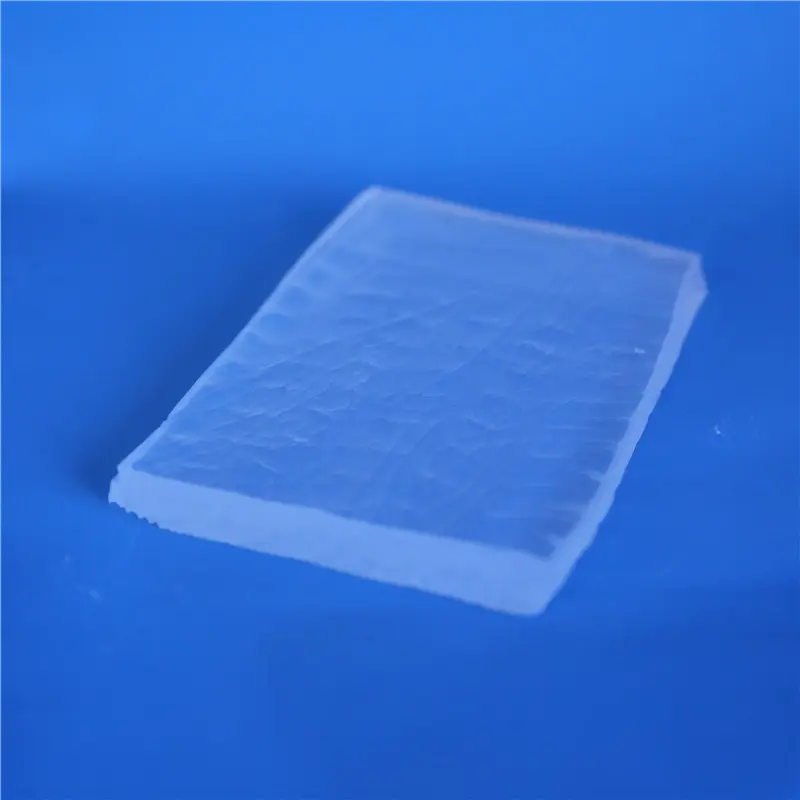

Silicone

Silica gel material has good temperature resistance and elasticity, which can maintain flexibility in a large temperature range and provide effective sealing protection for the battery, but not very tolerant to some chemical solvents, and it may degrade under certain conditions.

Fluorine rubber

Fluorine rubber has excellent high temperature resistance, corrosion resistance characteristics, suitable for high-performance lithium battery applications, can effectively prevent electrolyte leakage. However, Fluorine rubber is relatively expensive and susceptible to ambient temperature changes.

Thermoplastic elastomer (TPE)

Thermoplastic elastomer (TPE) is combined with the plasticity of plastic and the elasticity of rubber, suitable for mass production, good sealing performance. However, Thermoplastic elastomer may lose some performance in some harsh chemical environments.

the effect of sealing material on battery performance

The choice of sealing material has a significant impact on the overall performance of lithium iron phosphate monomer batteries, mainly reflected in the following aspects:

The choice of sealing material has a significant impact on the overall performance of lithium iron phosphate monomer batteries, mainly reflected in the following aspects:

Chemical corrosion resistance: The corrosion resistance of the sealing material directly affects the service life of the battery and can prevent the reaction of the electrolyte with the external environment.

Thermal stability: With the charging and discharging process of the battery, the temperature will constantly change, and the thermal stability of the sealing material affects the safety of the battery to prevent battery leakage or short circuit fault caused by high temperature.

Mechanical strength: The mechanical properties of the sealing material are crucial to the structural stability of the battery. Good mechanical strength can effectively avoid the failure of the seal caused by external impact or pressure.

Conclusion

The sealing material of the positive cap plays a crucial role in the lithium iron phosphate monomer battery, and its selection and application directly affect the safety, stability and service life of the battery. In-depth research and optimization of sealing material performance can not only improve the overall performance of the battery, but also promote the sustainable development of battery technology, which provides a solid foundation for the popularization of electric transportation and energy storage systems in the future. In the context of the increasing global focus on clean energy, the research and development of high-quality sealing materials is expected to open up new possibilities for the future of green energy.

Home energy storage product series

A lithium battery pack for home energy storage systems, which is compatible with solar panels and the sun The inverter can work together with the power grid to power household appliances, and it can also be used as a For off grid systems.

Extended reading

BMS protection working principle

BMS protection working principle BMS includes control IC, MOS switch,...

Safety protection level of battery pack

Safety protection level of battery pack Battery packs are widely...

THE ESSC Brand promise

Global supply

Our products sell well all over the world, covering many countries and regions, through the global logistics network, to provide customers with convenient purchasing experience.

Rigorous quality

We adhere to the highest quality control standards to ensure every product meets industry regulations and customer expectations, earning trust through consistent excellence.

Excellent service

With a customer-centric approach, we provide prompt responses, professional support, and personalized services, aiming to deliver the best user experience and long-term value.