Product testing Product testing is a key link to ensure...

Production technology

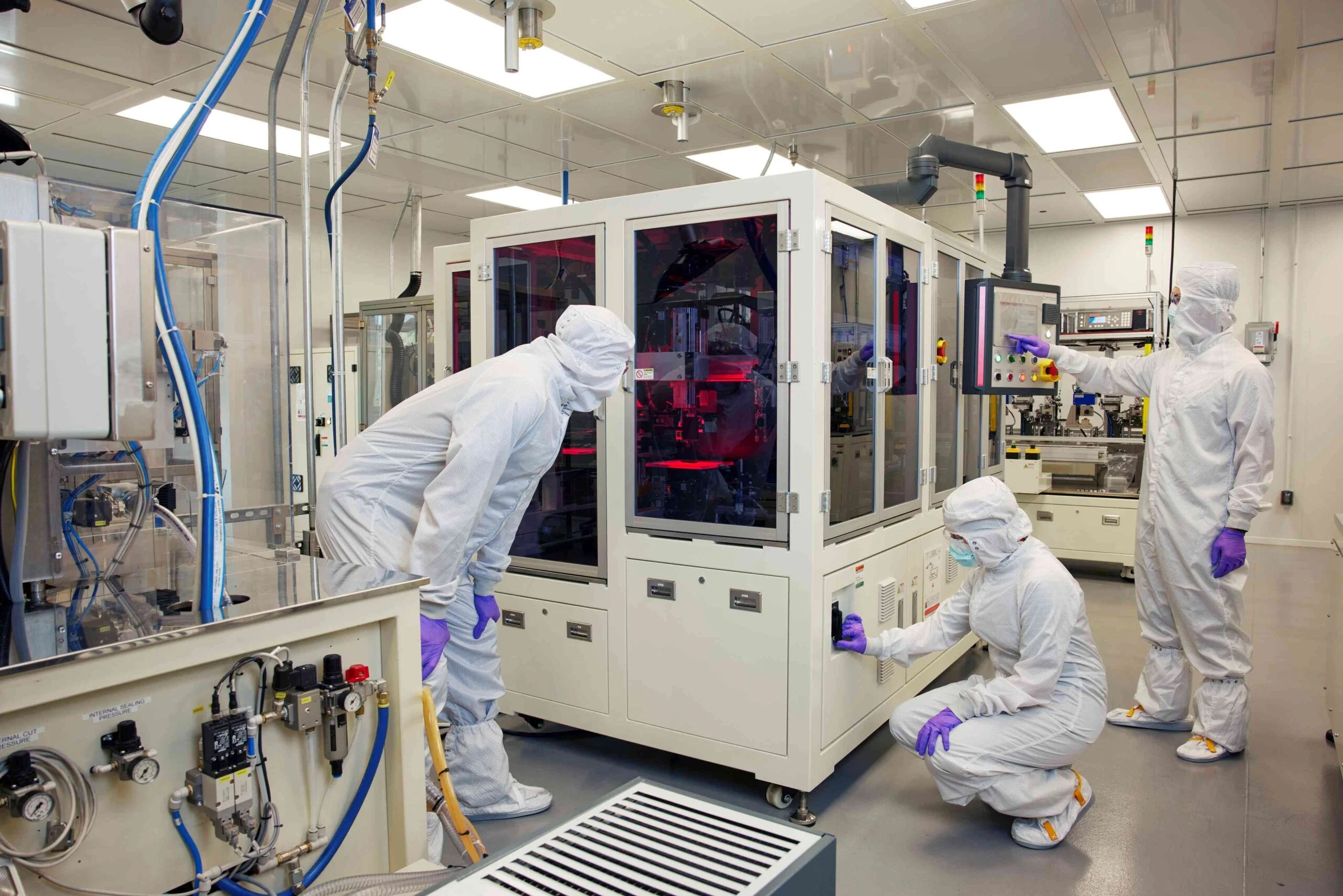

Battery production process refers to the manufacturing process from raw materials to the final product, including all the technologies, equipment and processes involved in battery production. Excellent production processes not only determine the quality, performance and consistency of the battery, but also affect production efficiency, cost control and sustainability. The production process of low-speed vehicle battery plays a crucial role in improving the energy density of the battery, extending the service life, ensuring safety and reducing the manufacturing cost.

Production technology

The production process of the battery covers all aspects from material preparation to final packaging, and the fine control of each aspect will directly affect the performance, cost, safety and service life of the battery. Precise production processes and efficient manufacturing processes can significantly improve the consistency and quality of batteries, reduce production costs in continuous optimization, and promote the continuous progress and popularization of battery technology in areas such as low-speed vehicles.

Production process summary

Material preparation

Select and handle positive and negative electrode materials, electrolyte and diaphragm to ensure the chemical performance and stability of the battery.

Electrode manufacturing and coating

Through the coating, pressing and cutting process, optimize the structure and performance of the electrode, improve the capacity and efficiency of the battery.

Battery assembly

Multiple battery cells are assembled into modules to ensure the reliability of mechanical and electrical connections.

Battery testing and commissioning

Rigorous performance, safety and conformance testing to ensure that batteries meet design standards.

Thermal management and packaging

Efficient thermal design and battery packaging ensure stable battery operation and prevent overheating.

Automation and continuous improvement

Automated production increases productivity and consistency, continuously optimizes processes to reduce costs and improve product quality.

low-speed car batteries

Low-speed vehicle battery is a kind of battery designed for low-speed electric vehicles, which has the characteristics of clean, environmental protection, high efficiency and economy, and is widely used in electric golf carts, low-speed electric vehicles (LSV), mobile vendors, campus transportation, cargo trucks and so on

Extended reading

Product packaging and delivery

Product packaging and delivery The packaging and delivery of battery...

Product information expansion

Product information expansion Understanding low-speed vehicle battery product information is...

Product composition

Low-speed lithium battery product composition Understanding the product composition of...

THE ESSC Brand promise

Global supply

Our products sell well all over the world, covering many countries and regions, through the global logistics network, to provide customers with convenient purchasing experience.

Rigorous quality

We adhere to the highest quality control standards to ensure every product meets industry regulations and customer expectations, earning trust through consistent excellence.

Excellent service

With a customer-centric approach, we provide prompt responses, professional support, and personalized services, aiming to deliver the best user experience and long-term value.