Production process 10- Formation In the UPS (uninterruptible power supply)...

Production process 8- baking

In the UPS (uninterruptible power supply) production process, baking is an important step after the battery unit packaging, the main purpose is to remove the water inside the battery, prevent battery short circuit and improve the safety of the battery. The following are the main steps and process requirements of the baking process:

main content

Preparation work

Before baking, it is necessary to clean the baking box, remove the dust and foreign matter in the box and baking clip, and prevent the dust from entering the inside of the battery cell during baking.

Trial run

Open the main baking power switch, and vacuum valve, compressed gas valve. After baking, enter the main operation interface, press manual operation to enter the manual operation interface; Display layer number and select button corresponding to each layer oven: heating, vacuum, nitrogen filling; Select vacuum, first test vacuum the oven, vacuum when the vacuum reaches -90KPA, then fill nitrogen, to check whether the equipment vacuum and nitrogen filling operation is normal.

Start heating

After baking confirmation, enter the manual operation interface; Activate the oven heating button to heat the oven.

Bake

Put the battery into the baking box for baking. There are two kinds of baking methods, contact baking and hot air circulation baking; Hot air circulation baking is to heat the gas through the heating unit, and then heat the battery through the circulation system.

Process inspection

During the baking process, the temperature and pressure in the baking box should be checked regularly to ensure that it is within the specified range.

Charge and discharge nitrogen

As needed, nitrogen is charged and vented during the baking process to maintain a dry environment and remove moisture.

Process record

The whole baking process is recorded in detail, including temperature, pressure, time and other data.

To complete heat treatment

When the heat treatment time is up, turn off the oven and stop heating. After the oven cools to a safe temperature, you can open the oven door and take out the heat treated lithium battery.

Cleaning and maintenance

After the heat treatment is completed, clean the oven and working area in time to ensure the normal use of the oven and extend the life.

CONCLUSION

The baking process is an important part of the battery manufacturing process, its purpose is mainly to ensure the stability of the battery performance, safety and extend the service life. By removing the water, impurities and gases inside the battery, as well as heat treating and curing the materials inside the battery, the performance and safety of the battery can be significantly improved. In practical applications, the parameters of vacuum baking need to be adjusted according to the specific battery type and specifications to ensure the quality and performance of the battery.

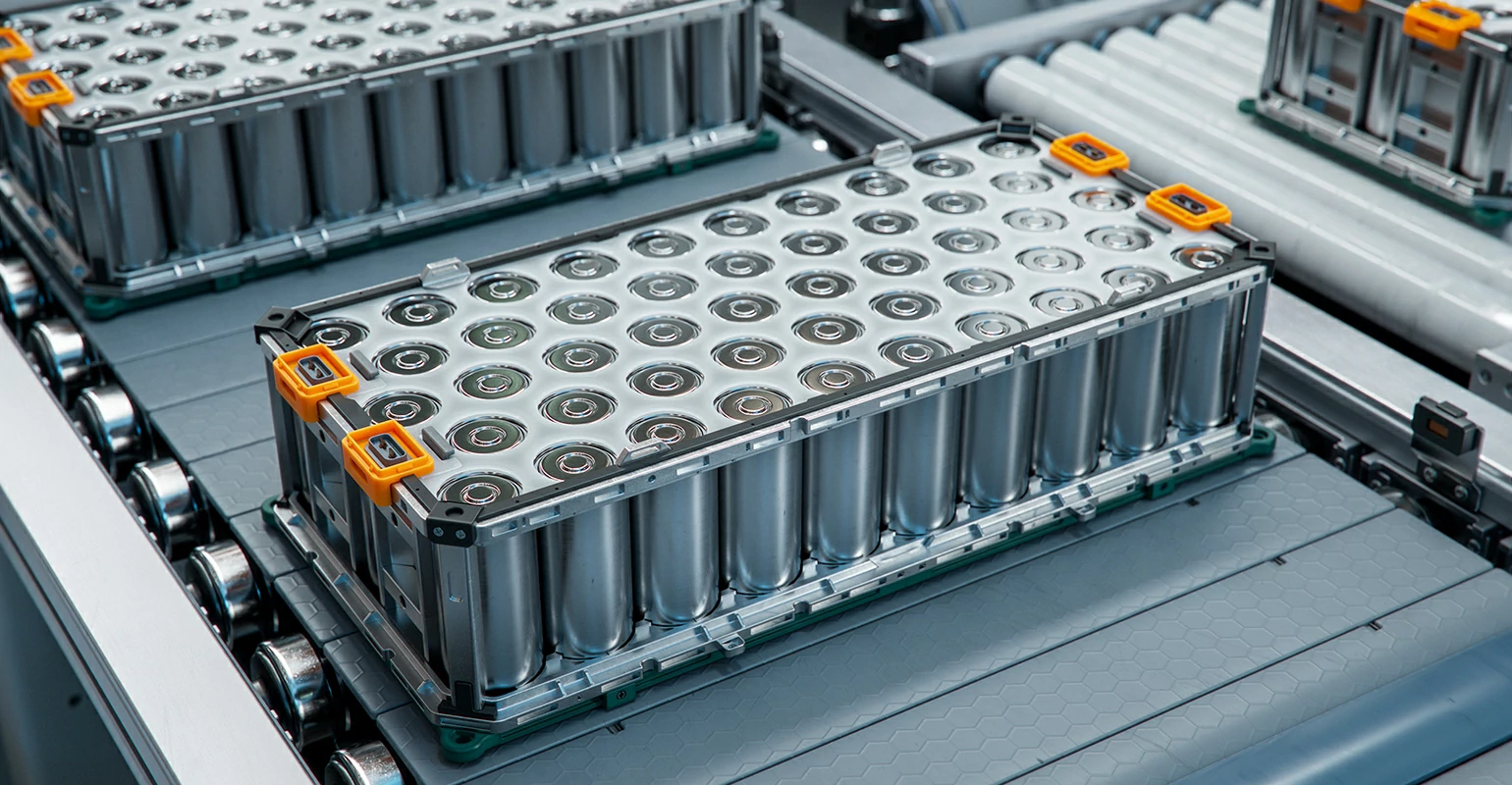

UPS BATTERY SERIES

UPS (Uninterruptible Power Supply) batteries are an important component of power supply systems designed to provide stable power support for electronic devices.

Extended reading

Production process 8- baking

Production process 8- baking In the UPS (uninterruptible power supply)...

Maintain the battery module after the capacity divider test

Maintain the battery module after the capacity divider test Follow-up...

What are the pre-processing steps for the battery module before and after the capacitance test?

What are the pre-processing steps for the battery module before...

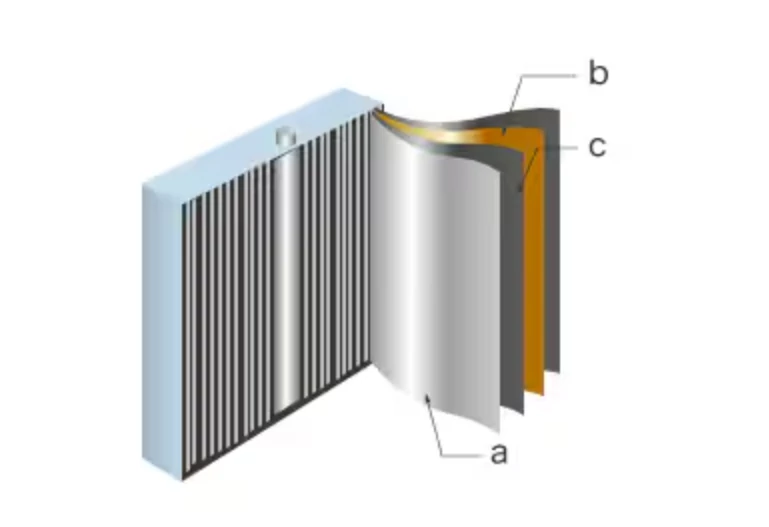

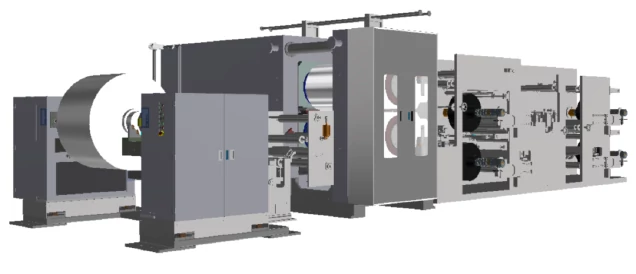

Production process 3- roll pressing

Production process 3- roll pressing Uninterruptible Power Supply (UPS) as...

The effect of drying temperature on battery life

The effect of drying temperature on battery life The effect...

THE ESSC Brand promise

Global supply

Our products sell well all over the world, covering many countries and regions, through the global logistics network, to provide customers with convenient purchasing experience.

Rigorous quality

We adhere to the highest quality control standards to ensure every product meets industry regulations and customer expectations, earning trust through consistent excellence.

Excellent service

With a customer-centric approach, we provide prompt responses, professional support, and personalized services, aiming to deliver the best user experience and long-term value.