Production process 11- forming In the UPS (uninterruptible power supply)...

Production process 7- Packaging

In the UPS (uninterruptible power supply) production process, the packaging process is the key step of placing the wound battery unit into a vacuum environment, injecting electrolyte, and packaging to form the final battery unit. Here's a breakdown of the process:

main content

Preparation before injection

Before injection, the soft pack cell is X-rayed to ensure the parallelism of the core, and then enters the drying room to deaerate. After a certain period of time in the drying room, the battery enters the process of liquid injection and pre-sealing.

Injection process

The electrolyte is injected into the sealed chamber through the quantitative pump. After the battery is put into the liquid injection chamber, the vacuum pump vacuums the liquid injection chamber to form a vacuum environment inside the battery. Insert the injection nozzle into the battery injection port, open the electrolyte injection valve, and pressurize the electrolyte chamber with nitrogen to 0.2-1.0Mpa. After holding the pressure for a certain period of time, the injection chamber is discharged to normal pressure. This process helps the electrolyte to fully infiltrate with the battery positive and negative materials and diaphragm.

Maintenance of vacuum environment

After injecting the electrolyte, use the injection machine or external equipment to vacuum the cavity of the injection machine, so that the electrode coil core after injecting the electrolyte is in a vacuum environment, the vacuum degree is -0.085-0.095Mpa, and the maintenance is 80-120 seconds. This helps reduce the impact of bubbles on the quality of the battery and allows bubbles in the electrolyte to escape.

Secondary injection and vacuum maintenance

Inject more electrolyte into the first battery roll so that it fills but does not overflow. Then vacuum again to -0.085-0.095Mpa for 150-250 seconds. This further reduces the appearance of dry zones on the electrode sheet and improves the penetration of the electrolyte into the electrode sheet.

Standing in an inert atmosphere

The second battery coil is placed in an inert atmosphere for 60-80 seconds, usually in a nitrogen atmosphere, so that the electrolyte is evenly dispersed and uniform and efficient penetration of the electrolyte to the electrode sheet is achieved.

Pressure treatment

The liquid injection machine continues to pass inert gas, so that the pressure of the cavity is 1.5×10^5Pa to 2.0×10^5Pa, and the battery coil is placed in the high pressure environment for 200-250 seconds to complete the penetration of the electrolyte to the electrode.

Battery seal

After the injection is complete, the battery needs to be sealed. In the vacuum environment, the gas inside the battery cell is extracted and sealed to form a soft pack battery without liquid injection. During the sealing process, the guillotine pricks the air bag, vacuums out the gas and a small part of the electrolyte in the air bag, and finally cuts the encapsulated battery to remove the air bag.

Follow-up process

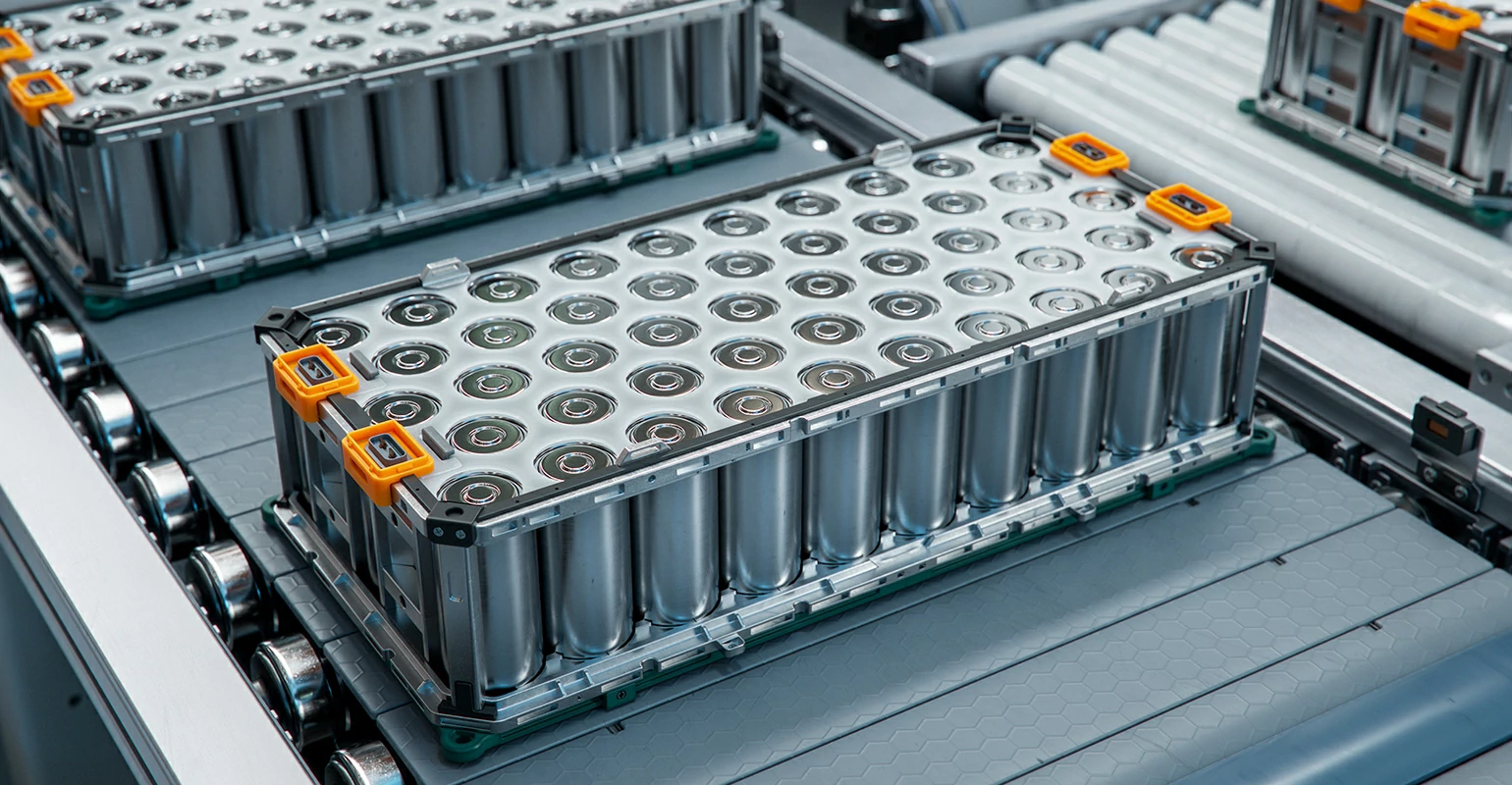

After the packaging is completed, the cell will undergo formation, fixture shaping and other processes to form a stable SEI film and ensure the size and performance of the cell.

CONCLUSION

Through the packaging process, you can ensure the safety, stability, and performance of the battery unit, and provide reliable power support for the UPS.

UPS BATTERY SERIES

UPS (Uninterruptible Power Supply) batteries are an important component of power supply systems designed to provide stable power support for electronic devices.

Extended reading

Production process 5- Welding electrode lugs

Production process 5- Welding electrode lugs Uninterruptible Power Supply (UPS)...

What are the pre-processing steps for the battery module before and after the capacitance test?

What are the pre-processing steps for the battery module before...

Impact of deviation correction accuracy on battery performance

Impact of deviation correction accuracy on battery performance The impact...

Production process 8- baking

Production process 8- baking In the UPS (uninterruptible power supply)...

Production Process 2- Coating

Production Process 2- Coating Uninterruptible Power Supply (UPS) is an...

THE ESSC Brand promise

Global supply

Our products sell well all over the world, covering many countries and regions, through the global logistics network, to provide customers with convenient purchasing experience.

Rigorous quality

We adhere to the highest quality control standards to ensure every product meets industry regulations and customer expectations, earning trust through consistent excellence.

Excellent service

With a customer-centric approach, we provide prompt responses, professional support, and personalized services, aiming to deliver the best user experience and long-term value.