Production process 10- Formation In the UPS (uninterruptible power supply)...

Production process 5- Welding electrode lugs

Uninterruptible Power Supply (UPS) plays a vital role in modern power systems, ensuring the normal operation of equipment in the event of a power interruption. In the production process of UPS, the welding pole is a key link, which directly affects the performance, safety and reliability of the equipment. This article will introduce the welding pole lugs in the main UPS production process in detail.

main content

Purpose and importance of welding pole ears

The welding pole is to connect the positive and negative leading wires (pole ears) of the battery with the electrodes inside the battery to ensure that the battery can safely and effectively input and output electrical energy. This step is essential to ensure the safety and electrical performance of the battery.

The main steps

Preparation

Clean the welding area of the lug and electrode sheet, remove any oxidation layer, oil or impurities, and ensure that the welding surface is clean.

Positioning and fixing

The pole lug is accurately placed in the predetermined position of the electrode sheet, fixed with a special fixture or mold, and ensure that the pole lug is aligned with the electrode sheet and stable when welding.

Set welding parameters

Adjust the parameters of the ultrasonic welding machine according to the electrode material (such as aluminum, copper or composite) and thickness, including frequency (commonly 20kHz or 40kHz), amplitude, welding pressure and welding time.

Welding operation

Start the ultrasonic welding equipment, apply pressure to the welding area with the help of the protective plate (if available), and start high-frequency vibration. The vibration generates local friction heat, which causes plastic deformation and intermolecular bonding between the contact surface of the pole ear and the electrode sheet to form a firm welding point.

Cooling and inspection

After the welding is completed, let the welding area cool naturally, and then carry out appearance and function inspection to ensure the welding quality, such as no cracks, virtual welding and other defects.

Cooling and inspection

After the welding is completed, let the welding area cool naturally, and then carry out appearance and function inspection to ensure the welding quality, such as no cracks, virtual welding and other defects.

Welding process

Spot welding

Spot welding is one of the most commonly used welding methods in UPS production. The heat generated by the current at the contact point melts the pole and the battery pole, forming a fixed connection. Spot welding speed is fast, suitable for mass production.

Laser welding

Laser welding locally heats the welding point through a high-energy laser beam, which has the advantages of high welding accuracy, small heat-affected zone and strong welding, but the equipment cost is relatively high.

Ultrasonic welding

The process produces local melting of the contact surface of the material through ultrasonic vibration, which is suitable for the welding of thin pole ears, and can achieve fast and pollution-free connection.

CONCLUSION

The electrode lug welding is a key step in the battery production, which directly affects the performance and safety of the battery. Through precise control of welding parameters and the use of advanced welding technology, the welding quality of the battery pole can be ensured, so as to produce a battery with reliable performance.

UPS BATTERY SERIES

UPS (Uninterruptible Power Supply) batteries are an important component of power supply systems designed to provide stable power support for electronic devices.

Extended reading

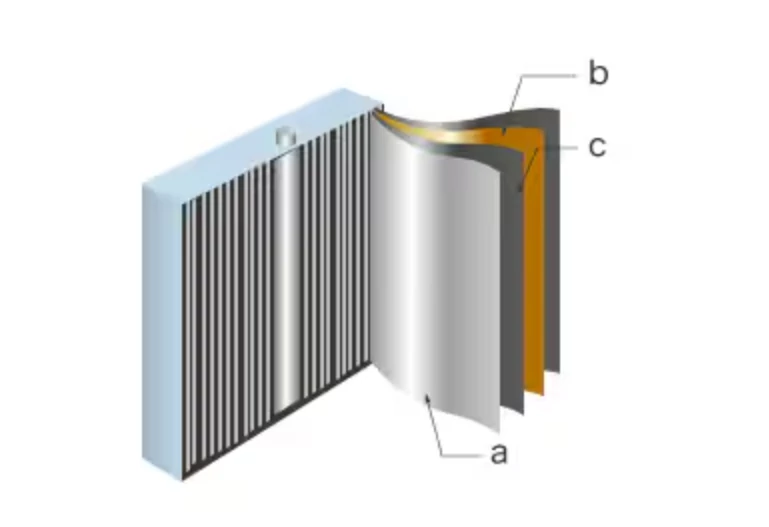

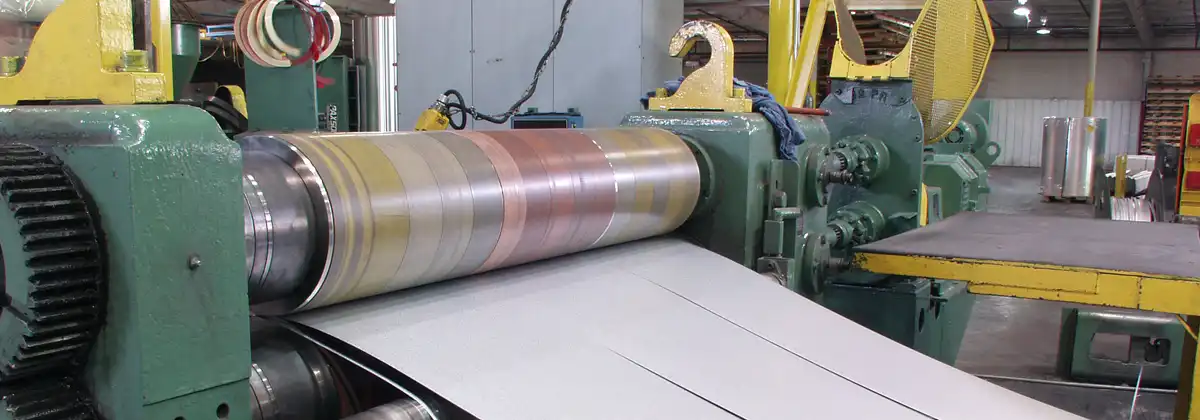

Production process 4-Cutting and slitting

Production process 4-Cutting and slitting Uninterruptible Power Supply (UPS) is...

Production Process 2- Coating

Production Process 2- Coating Uninterruptible Power Supply (UPS) is an...

Maintain the battery module after the capacity divider test

Maintain the battery module after the capacity divider test Follow-up...

Production Process 1- Ingredients

Production Process 1- Ingredients The production of Uninterruptible Power Supply...

Production process 7- Packaging

Production process 7- Packaging In the UPS (uninterruptible power supply)...

THE ESSC Brand promise

Global supply

Our products sell well all over the world, covering many countries and regions, through the global logistics network, to provide customers with convenient purchasing experience.

Rigorous quality

We adhere to the highest quality control standards to ensure every product meets industry regulations and customer expectations, earning trust through consistent excellence.

Excellent service

With a customer-centric approach, we provide prompt responses, professional support, and personalized services, aiming to deliver the best user experience and long-term value.