Production process 9- liquid injection In the UPS (uninterruptible power...

Production process 3- roll pressing

Uninterruptible Power Supply (UPS) as a key device to ensure the continuity of power supply, every link in its production process is critical. As an important step in the UPS manufacturing process, rolling plays an important role in improving the performance and stability of the product. This article will introduce the roller pressing process of UPS production process in detail.

main content

Purpose of rolling

The main purpose of the rolling process is to obtain electrode sheets that meet the design requirements, enhance the bonding strength of the active substance with the fluid collector foil (copper foil or aluminum foil), and prevent the active substance from peeling off during the electrolyte immersion and battery use.

By rolling, the surface of the pole sheet can be kept smooth and flat, preventing the burr on the surface of the pole sheet from penetrating the diaphragm and causing a short circuit of the battery, thereby improving the energy density of the battery.

Roller pressing can also compact the electrode material coated in the electrode collector fluid, reduce the volume of the electrode, improve the energy density of the battery, and improve the cycle life and safety performance of the lithium battery.

Rolling process

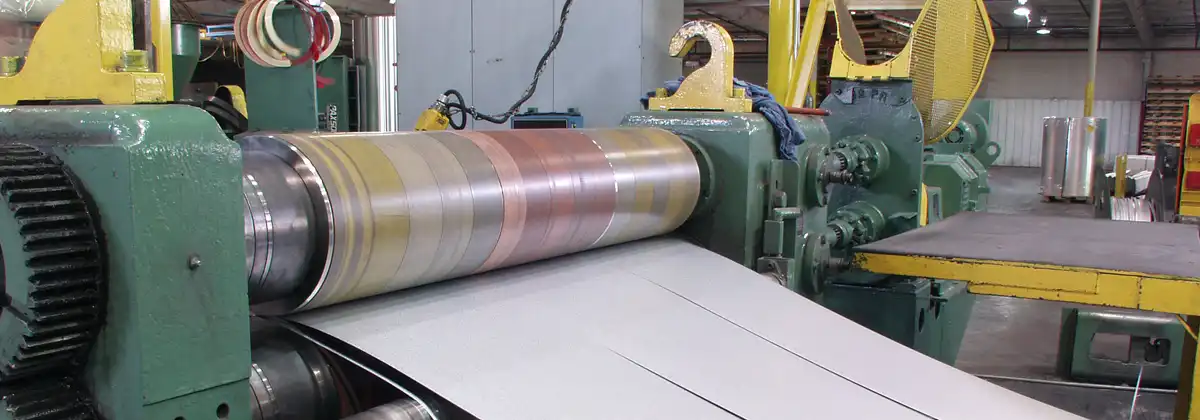

The rolling process is carried out after the coating is completed and the pole piece is dried to avoid the phenomenon of powder dropping and film falling off during the rolling process.

Before rolling, the electrical slurry coating on copper foil or aluminum foil is a semi-fluid, semi-solid granular medium with a certain dispersion and fluidity. During the rolling process, the electric slurry particles have a small displacement movement to fill the gap, so as to position each other under compaction.

Roll technology

Rolling is a continuous process in which the electric slurry particles are attached to the copper foil or aluminum foil, and are constantly bitten into the roll cracks by friction, and are compacted by the roll into a battery electrode with a certain density.

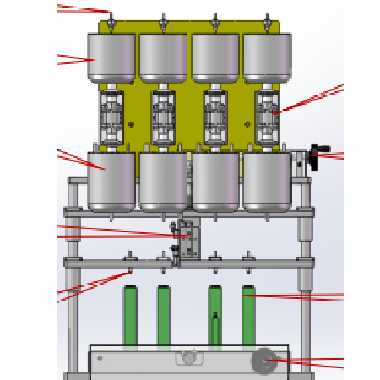

The roller press can be divided according to the drive mode and pressure mode, and the hydraulic cylinder pressing structure is the mainstream pressure mode at present, which can exert greater pressure and achieve better compaction effect.

Impact of roll pressure on battery performance

Roller pressing can increase the compaction density of the battery electrode sheet, thereby increasing the volume energy density of the battery, which is essential to improve the battery performance.

Roller pressing can also improve the conductivity of the battery electrode sheet because the particles are pressed into the substrate film during compaction, increasing the contact between the electrode material and the collector.

CONCLUSION

In summary, the rolling process plays a key role in the battery production process of UPS, which not only affects the physical characteristics of the battery, but also directly relates to the performance and safety of the battery. By precisely controlling the rolling process, the quality of the battery electrode can be ensured, resulting in a battery with reliable performance.

UPS BATTERY SERIES

UPS (Uninterruptible Power Supply) batteries are an important component of power supply systems designed to provide stable power support for electronic devices.

Extended reading

Production process 7- Packaging

Production process 7- Packaging In the UPS (uninterruptible power supply)...

Production process 4-Cutting and slitting

Production process 4-Cutting and slitting Uninterruptible Power Supply (UPS) is...

Production Process 2- Coating

Production Process 2- Coating Uninterruptible Power Supply (UPS) is an...

Impact of deviation correction accuracy on battery performance

Impact of deviation correction accuracy on battery performance The impact...

The effect of drying temperature on battery life

The effect of drying temperature on battery life The effect...

THE ESSC Brand promise

Global supply

Our products sell well all over the world, covering many countries and regions, through the global logistics network, to provide customers with convenient purchasing experience.

Rigorous quality

We adhere to the highest quality control standards to ensure every product meets industry regulations and customer expectations, earning trust through consistent excellence.

Excellent service

With a customer-centric approach, we provide prompt responses, professional support, and personalized services, aiming to deliver the best user experience and long-term value.