Production process 10- Formation In the UPS (uninterruptible power supply)...

Production process 11- forming

In the UPS (uninterruptible power supply) production process, molding refers to the battery unit after formation through a series of process steps, and finally become the UPS battery module process. The following are the main steps and key points of the forming process:

main content

Battery cell cleaning

After the formation process, the surface of the battery unit needs to be cleaned to remove possible impurities and residues to ensure that the cleanliness of the battery unit meets the requirements of subsequent assembly.

Battery connection

After cleaning, the battery units are connected side by side according to the design requirements to form a battery module. In this step, the batteries are connected to each other by welding, plugging, or bolting.

Module fixation

Secure the connected battery cell in the module box coated with adhesive. This step ensures that the position of the battery unit in the module is stable, preventing displacement during use.

Electrical connection

The connected battery units are connected via a harness or bus to ensure the smooth flow of current. This step is key to the electrical performance of the battery module.

Module package

After securing the battery unit and making electrical connections, you need to cover the module box to form a sealed battery module. This step may involve welding, riveting or the use of special fasteners to ensure the tightness of the module box.

Component assembly

Multiple modules are placed in the battery pack and connected to each other to form a complete battery pack. The number of cells and modules in a battery pack will vary depending on the battery model and application.

Battery Management System (BMS) Installation

After the battery pack is assembled, a battery management system (BMS) is installed to assess the battery's charging status and service life. The battery Monitoring Unit (CMU) in the BMS assesses the condition of the battery and balances it to ensure its safe use.

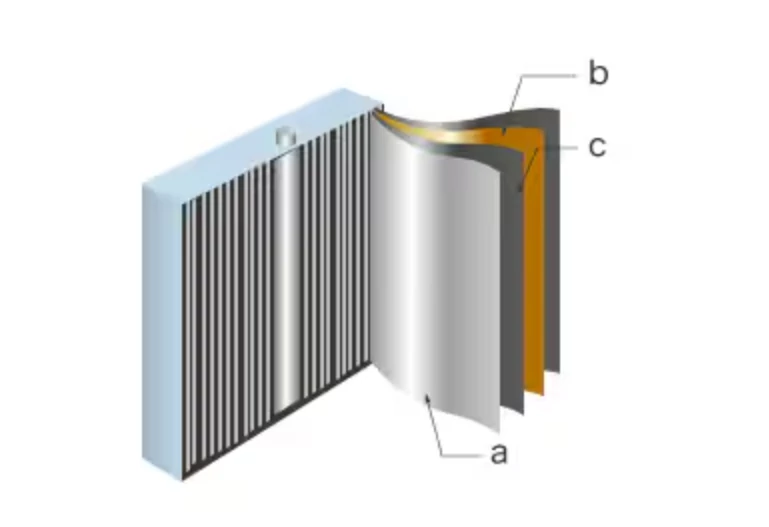

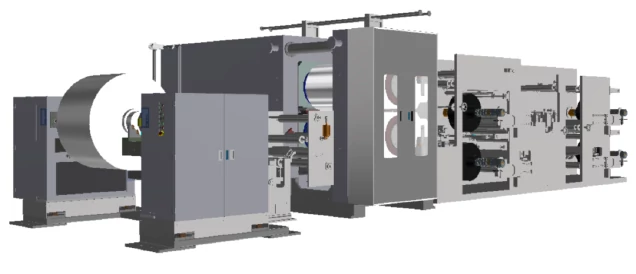

Optimization of molding technology

Depending on the material selection of the battery case, the forming technology can be stamped aluminum welding, extrusion aluminum friction stir and casting. For example,

Composite molding process: For the composite battery case, the molding process includes autoclave, resin transfer molding (RTM), vacuum introduction, injection, extrusion and injection. During production and manufacturing, the most appropriate manufacturing process can be selected based on component characteristics, cost and the type of composite material selected.

CONCLUSION

Through the above molding process, the formed battery unit is processed into a UPS battery module to provide stable and reliable power support for the UPS system.

UPS BATTERY SERIES

UPS (Uninterruptible Power Supply) batteries are an important component of power supply systems designed to provide stable power support for electronic devices.

Extended reading

Production Process 1- Ingredients

Production Process 1- Ingredients The production of Uninterruptible Power Supply...

Impact of deviation correction accuracy on battery performance

Impact of deviation correction accuracy on battery performance The impact...

Production process 3- roll pressing

Production process 3- roll pressing Uninterruptible Power Supply (UPS) as...

Production process 12- Capacity test

Production process 12- Capacity test In the UPS (uninterruptible power...

Production process 8- baking

Production process 8- baking In the UPS (uninterruptible power supply)...

THE ESSC Brand promise

Global supply

Our products sell well all over the world, covering many countries and regions, through the global logistics network, to provide customers with convenient purchasing experience.

Rigorous quality

We adhere to the highest quality control standards to ensure every product meets industry regulations and customer expectations, earning trust through consistent excellence.

Excellent service

With a customer-centric approach, we provide prompt responses, professional support, and personalized services, aiming to deliver the best user experience and long-term value.