Maintain the battery module after the capacity divider test Follow-up...

Production Process 1- Ingredients

The production of Uninterruptible Power Supply (UPS) is a complex system engineering involving many links, of which the batching link is a key part to ensure product quality and production efficiency. This paper will deeply discuss the UPS production process of the batching link.

main content

Raw material selection

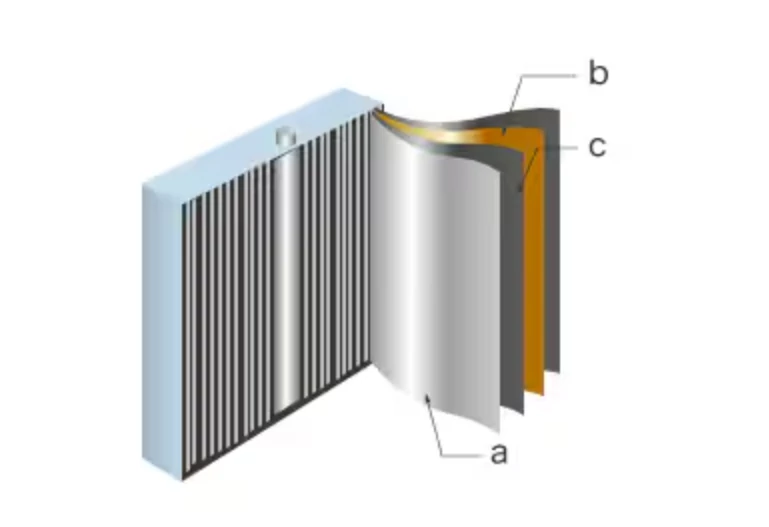

The production process of UPS begins with the selection of raw materials. Core components include batteries and transformers. When choosing a battery, it is necessary to consider factors such as the capacity, charge and discharge performance and life of the battery, and usually choose lithium batteries with higher energy density and longer service life. When choosing a transformer, factors such as the rated power, input voltage range and output voltage characteristics of the transformer need to be considered to ensure that the needs of different types of users are met.

Component procurement

After the design is determined, the next step is to procure the necessary components for the UPS. This includes batteries, circuit boards, transformers, capacitors and other electronic components. Manufacturers often work with suppliers to ensure the availability and quality of these components.

Material inspection

When these materials arrive at the plant, they first need to be inspected to ensure that they are usable. If the material passes the inspection, the inspection results are recorded and the product is then manufactured. If the material does not pass the inspection, it needs to be returned to the supplier and wait for the arrival of the replacement goods.

Material preparation

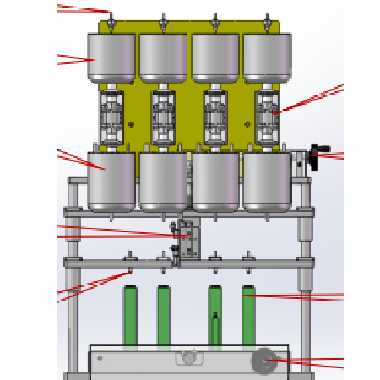

After material inspection, materials need to be prepared for manufacturing use. This may include cutting, molding, or other pre-treatment steps to the materials to ensure they can meet the needs of subsequent assembly and installation.

Material records

In the process of material inspection and preparation, all relevant inspection and treatment results need to be recorded in detail to facilitate subsequent traceability and quality control.

CONCLUSION

The batching process is the basis of the UPS production process, which directly affects the performance and quality of the final product. Through careful selection and preparation of raw materials, you can ensure that UPS equipment meets the expected performance standards in subsequent production and use.

UPS BATTERY SERIES

UPS (Uninterruptible Power Supply) batteries are an important component of power supply systems designed to provide stable power support for electronic devices.

Extended reading

Production process 9- liquid injection

Production process 9- liquid injection In the UPS (uninterruptible power...

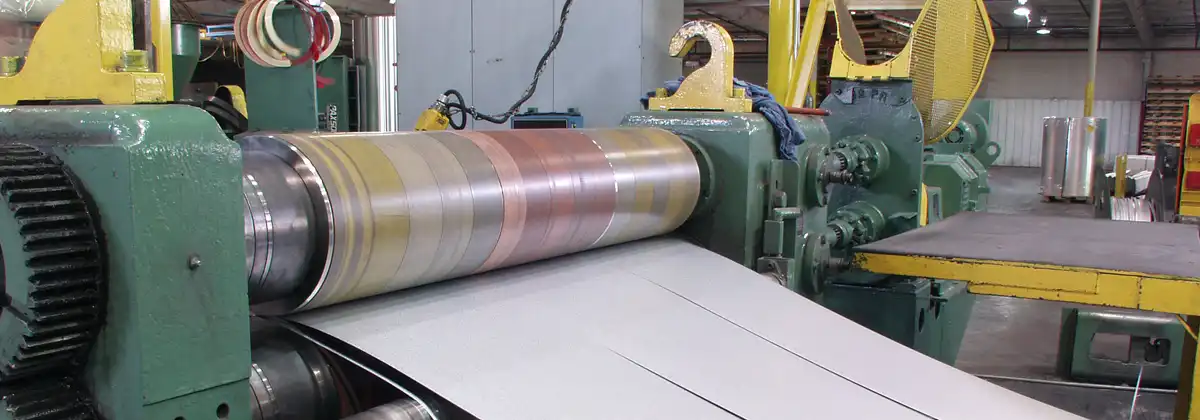

Production process 4-Cutting and slitting

Production process 4-Cutting and slitting Uninterruptible Power Supply (UPS) is...

Impact of deviation correction accuracy on battery performance

Impact of deviation correction accuracy on battery performance The impact...

Production process 10- Formation

Production process 10- Formation In the UPS (uninterruptible power supply)...

Production Process 1- Ingredients

Production Process 1- Ingredients The production of Uninterruptible Power Supply...

THE ESSC Brand promise

Global supply

Our products sell well all over the world, covering many countries and regions, through the global logistics network, to provide customers with convenient purchasing experience.

Rigorous quality

We adhere to the highest quality control standards to ensure every product meets industry regulations and customer expectations, earning trust through consistent excellence.

Excellent service

With a customer-centric approach, we provide prompt responses, professional support, and personalized services, aiming to deliver the best user experience and long-term value.