The type of battery sealing ring Battery sealing ring is...

Process of winding

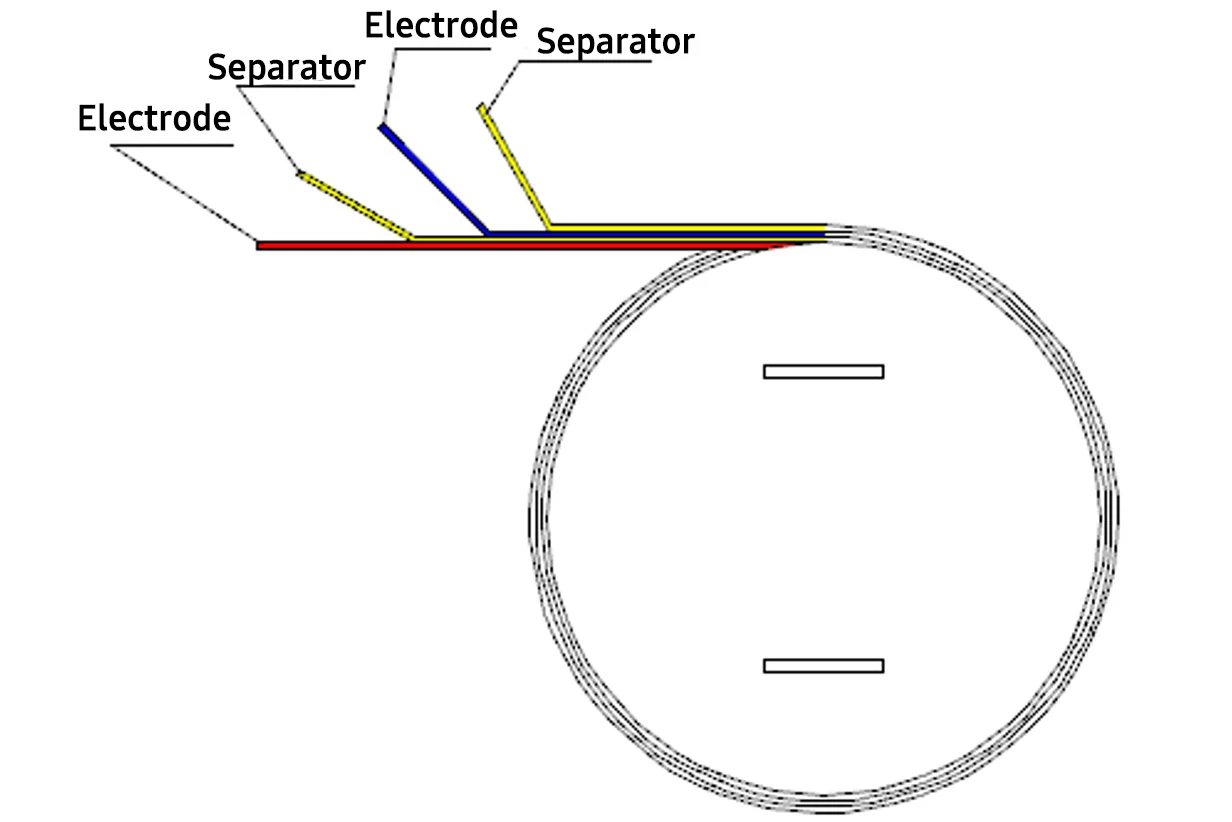

After laser cutting the pole piece, through the rotation of the needle, the pole piece is rolled into a layer on layer covering the core shape, the normal way of covering the diaphragm, positive electrode, diaphragm, negative electrode. Generally, there are round and oval needles. Theoretically, the rounder the needle is, the better the coil core fits, but the round needle makes the pole ear turn over seriously. In the process of winding, CCD is used to detect and correct the distance between positive and negative electrodes, and the distance between positive and negative electrodes and diaphragm.

The diaphragm plays the role of separating the positive and negative electrodes, preventing the internal short circuit of the battery, allowing the free passage of electrolyte ions, and completing the electrochemical charge and discharge process.

Specific process

Positive Electrode Unwinding

Unwinding Deviation Correction: To ensure that the cathode material remains in the correct position during unwinding.

Process Deviation Correction: Making further adjustments during production to keep the material in the correct position.

Feeding Deviation Correction: correcting the deviation of the material before entering the next process.

Separator Unwinding

Separator 1 and Separator 2 (separator 1&2) : two kinds of separator materials are unrolled separately.

Unwinding Deviation Correction: To ensure that the diaphragm material remains in the correct position during unwinding.

Pre-rolling Inspection: Check the diaphragm before winding.

Negative Electrode Unwinding

Unwinding Deviation Correction: To ensure that the cathode material remains in the correct position during unwinding.

Process Deviation Correction: Making further adjustments during production to keep the material in the correct position.

Feeding Deviation Correction: correcting the deviation of the material before entering the next process.

Winding

The positive, diaphragm and negative materials are wound to form a battery cell.

CCD Inspection

A CCD camera was used to visually inspect the wrapped product to ensure quality.

NG Elimination

If a nonconforming product (NG) is found in the CCD inspection, it will be removed from the production line and will not enter the subsequent process.

Glue (adhere)

The qualified products are pasted to fix the battery cells.

Pre-press

The product after gluing is preloaded to ensure the density and structural stability of the battery cell.

Material Offloading

Preloaded products are loaded and unloaded from the production line, ready for subsequent packaging or testing.

Home energy storage product series

A lithium battery pack for home energy storage systems, which is compatible with solar panels and the sun The inverter can work together with the power grid to power household appliances, and it can also be used as a For off grid systems.

Extended reading

Battery sealing ring material

Battery sealing ring material With the rapid development of science...

THE ESSC Brand promise

Global supply

Our products sell well all over the world, covering many countries and regions, through the global logistics network, to provide customers with convenient purchasing experience.

Rigorous quality

We adhere to the highest quality control standards to ensure every product meets industry regulations and customer expectations, earning trust through consistent excellence.

Excellent service

With a customer-centric approach, we provide prompt responses, professional support, and personalized services, aiming to deliver the best user experience and long-term value.