User guide The use guide for tower backup energy storage...

Process flow

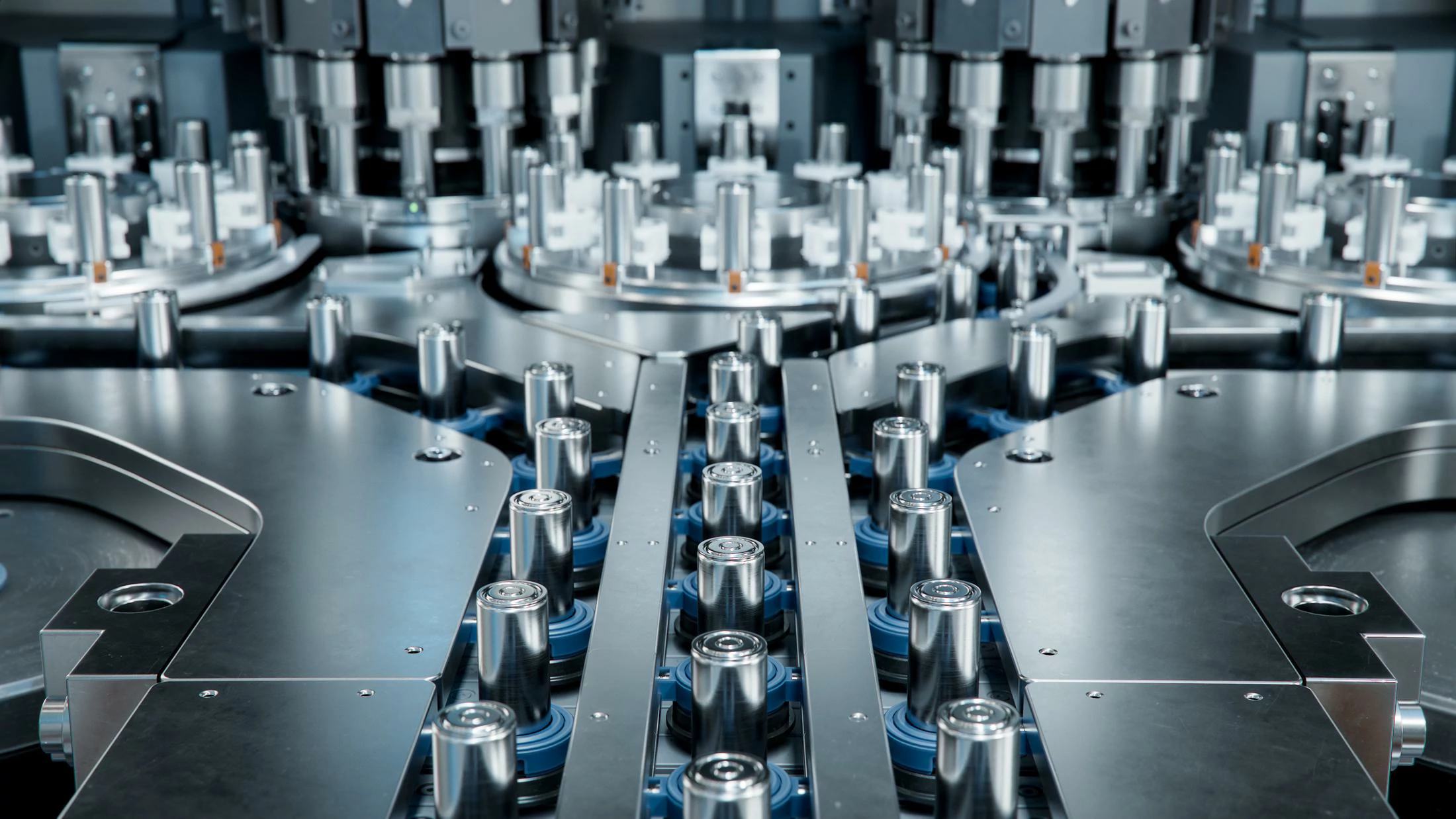

The process of tower backup energy storage battery includes four stages: cell manufacturing, module assembly, system integration and test optimization. In the monomer manufacturing stage, the battery performance is activated through the fabrication, assembly and formation of pole pieces; Module assembly combines monomers into modules; System integration to realize the linkage between battery and management system; Test optimization ensures the stability, safety and efficient operation of the battery system.

Process flow

The process flow of the tower backup energy storage battery realizes the efficient transformation from the basic material to the finished product of the system through the four stages of battery unit manufacturing, module assembly, system integration and test optimization. Each stage is interlinked to ensure the battery has high energy density, stable performance and long life, providing a reliable energy storage solution for multi-scenario applications.

Specific process flow

Cell manufacturing

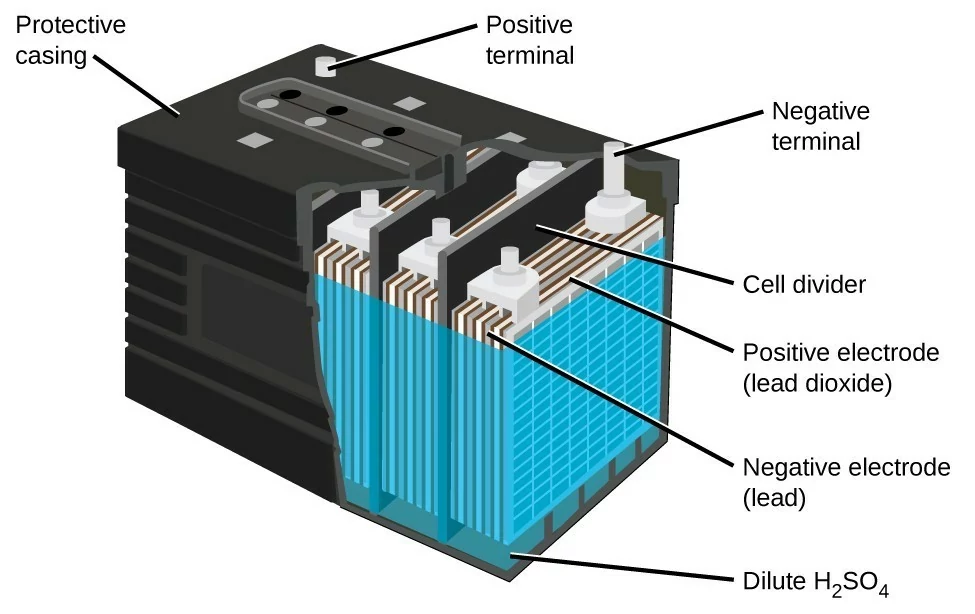

Material preparation: Select core materials such as positive electrode materials, negative electrode materials, electrolyte and diaphragm to ensure the basis of battery performance.

Electrode sheet production: the positive and negative electrode materials are mixed with conductive agents and binders, and evenly coated on the collector fluid (such as aluminum foil or copper foil) to form a positive and negative electrode sheet.

Battery assembly: the positive plate, diaphragm and negative plate are wound or laminated to form a battery cell and encapsulated in the battery shell.

Liquid injection and sealing: vacuum sealing after the injection of electrolyte to prevent leakage and ensure the chemical stability of the battery.

Formation and capacity separation: The first charge and discharge of the battery (formation process), activate the electrochemical reaction, and screen out the battery monomer that meets the standard.

Module assembly

Cell combination: Multiple battery cells are combined in series or parallel to form a battery module to meet the voltage and capacity requirements.

Structural fixation: The use of modular support structure to fix the battery cell, improve mechanical stability and safety.

Thermal management system: Integrated heat sink or temperature control system to ensure the temperature balance of the battery during operation.

System integration

Electrical connection: The battery module is connected with the power interface and electrical equipment to form a complete power transmission loop.

BMS (Battery Management System) : Install a battery management system to monitor battery voltage, current, and temperature in real time to ensure the safe operation of the system.

Protection system: Equipped with functional modules such as insulation, short circuit protection, and overcharge and overdischarge protection to improve the safety and stability of the battery system.

Test and optimization

Performance test: Capacity, cycle life, charge and discharge efficiency of the battery system are tested to ensure that they meet the design requirements.

Safety test: carry out high and low temperature, vibration, shock, short circuit protection and other safety tests to verify the stability of the battery under various working conditions.

System optimization: Analyze test data to optimize battery system configuration to improve overall efficiency and service life.

TOWER BACKUP BATTERY

With its integrated structural design, intelligent BMS monitoring, and standardized cabinet installation, ESS 48V series lithium iron phosphate batteries can provide reliable backup power for access network equipment, remote exchange, mobile communication, transportation equipment, emergency power and other systems.

Extended reading

Working principle and process flow

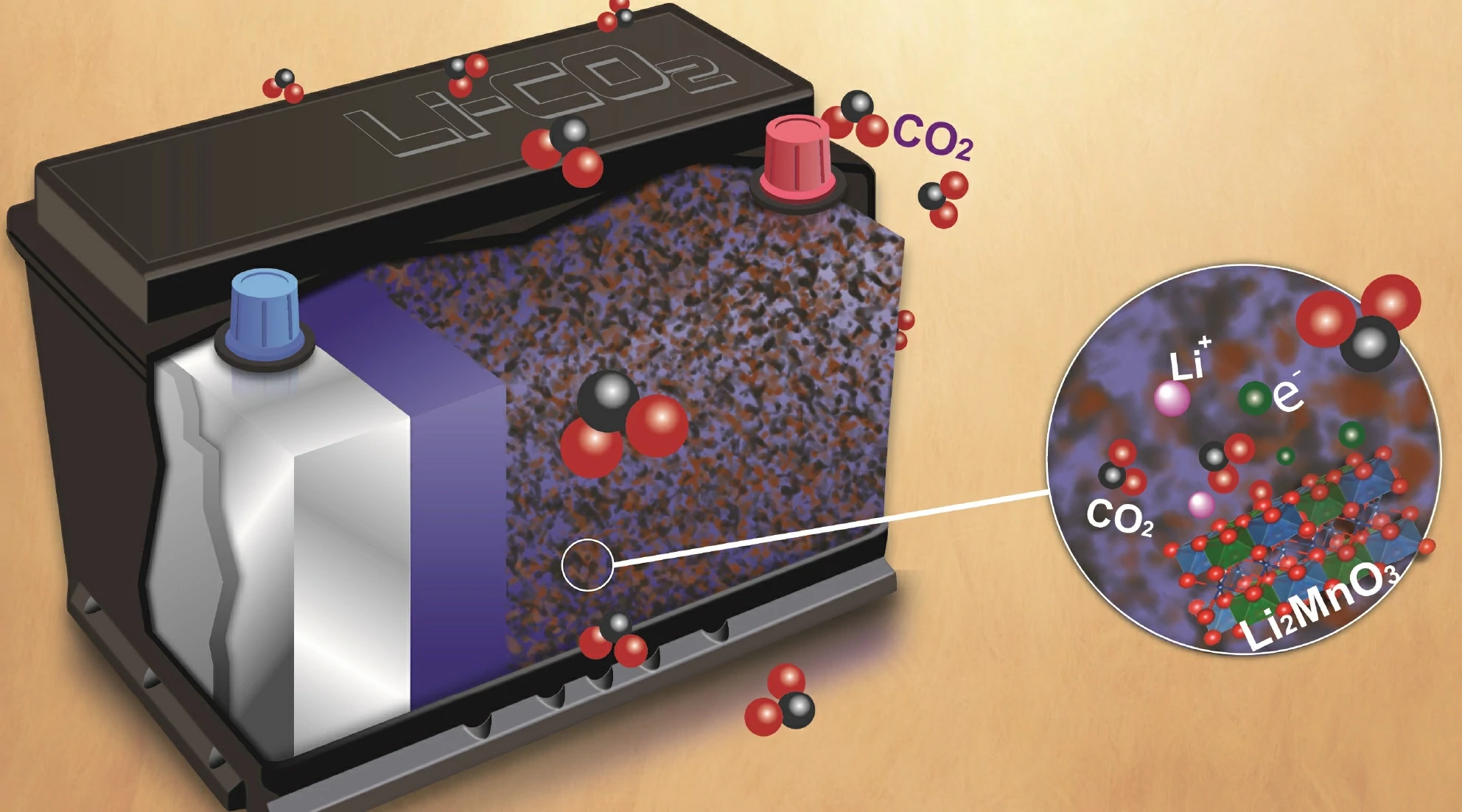

Working principle and process flow The working principle of the...

Product update direction and recycling

Product update direction and recycling The product update direction of...

Application scenario

Application scenario The application scenario of tower backup energy storage...

THE ESSC Brand promise

Global supply

Our products sell well all over the world, covering many countries and regions, through the global logistics network, to provide customers with convenient purchasing experience.

Rigorous quality

We adhere to the highest quality control standards to ensure every product meets industry regulations and customer expectations, earning trust through consistent excellence.

Excellent service

With a customer-centric approach, we provide prompt responses, professional support, and personalized services, aiming to deliver the best user experience and long-term value.