Positive homogenate Lithium battery positive homogenization is one of the...

Positive homogenate

Lithium battery positive homogenization is one of the key processes in the production of lithium battery, its purpose is to mix the positive active material, conductive agent, binder, etc., to form a paste suitable for coating. The following is a detailed introduction to the positive homogenate process:

Raw material preparation

The main raw materials of the positive homogenate include active materials (such as lithium iron phosphate LFP, ternary material NCM, etc.), conductive agents (such as SP, CNTs), binders (such as PVDF) and solvents (such as NMP).

Slurry preparation

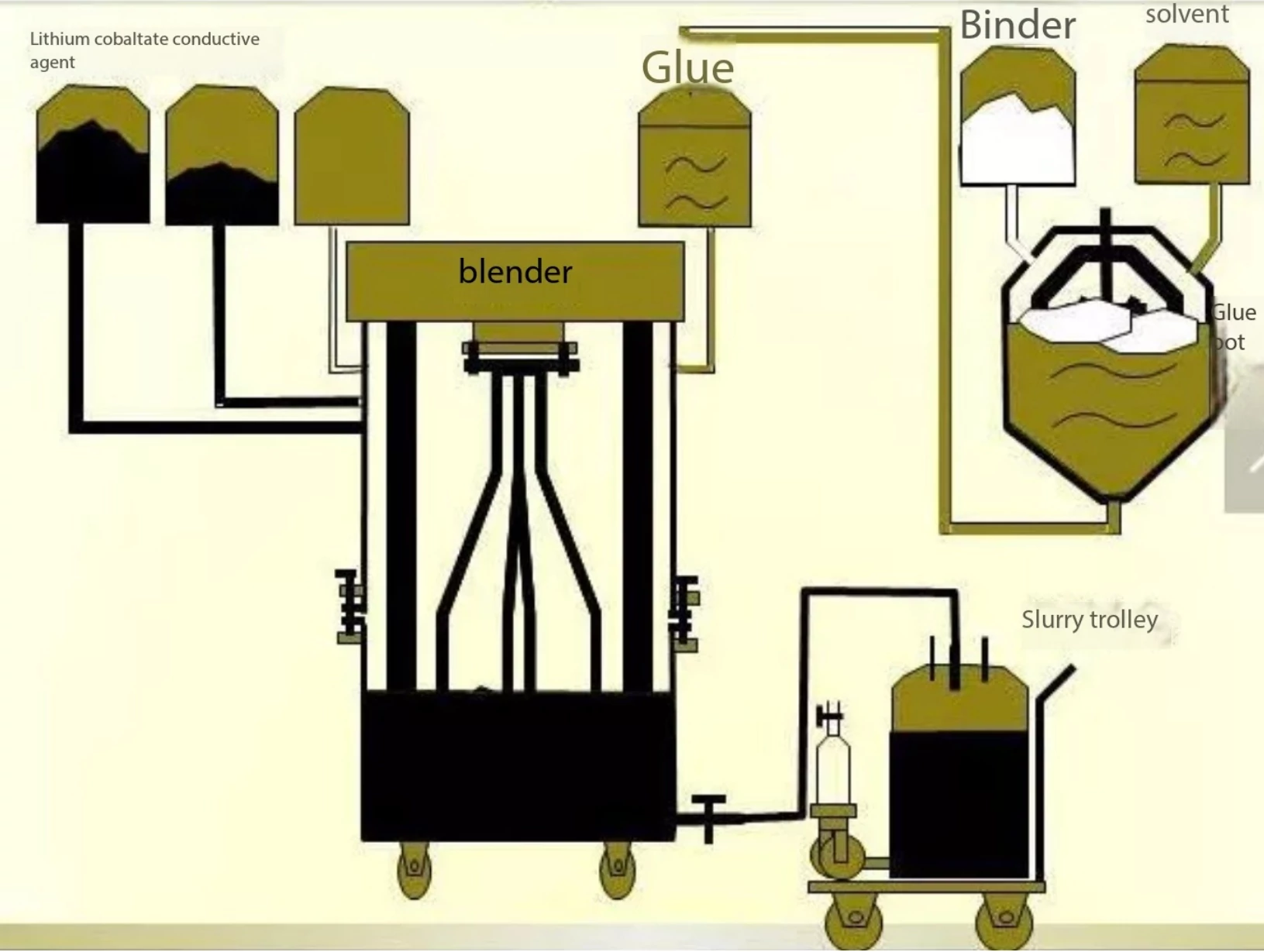

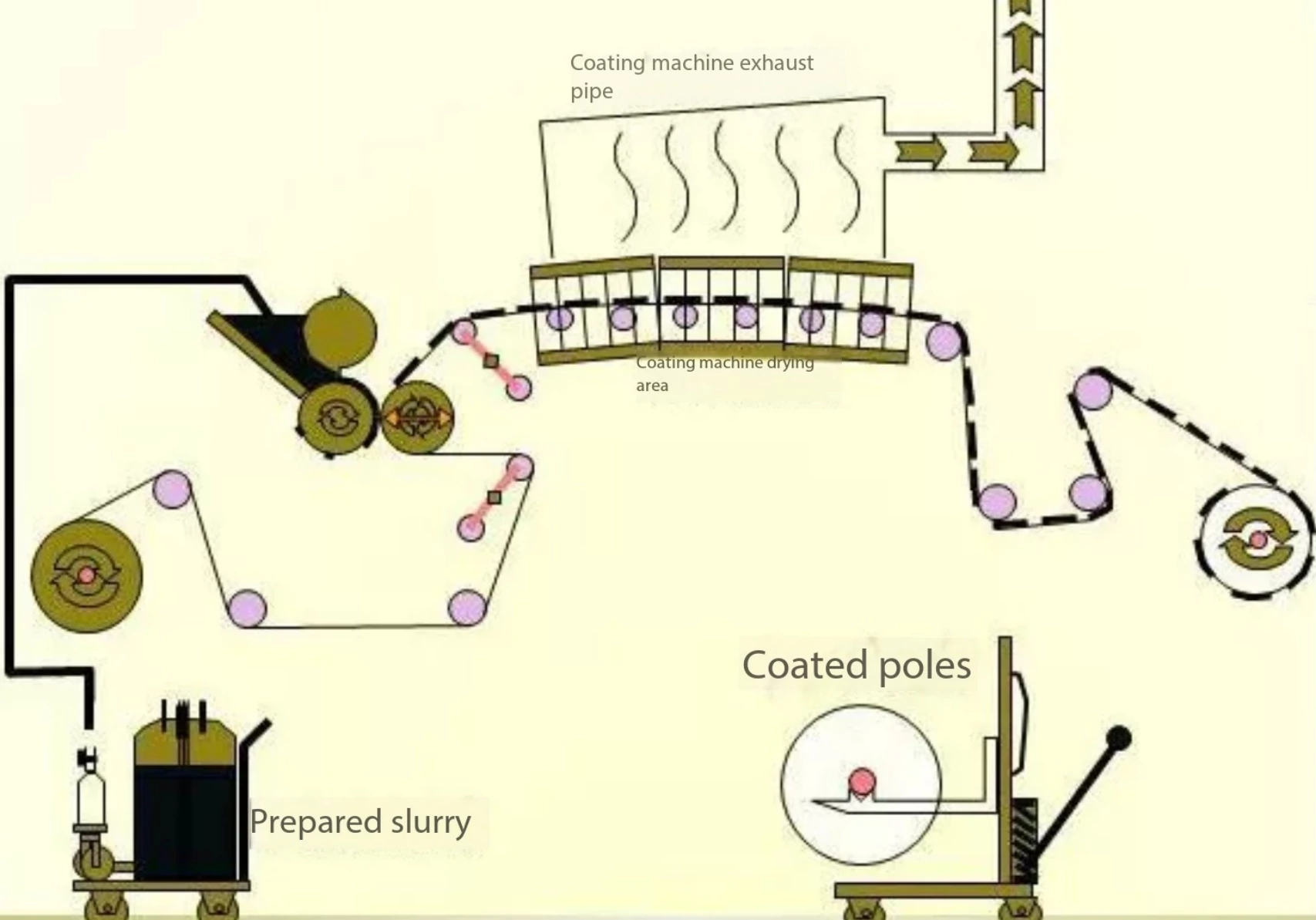

First, PVDF is dissolved in the solvent NMP to form a gel solution. Then, the active material and the conductive agent are evenly mixed and added to the glue mixture to form a non-Newtonian fluid slurry. Finally, a positive slurry is formed by adjusting the viscosity.

Mixing process

The mixing process is roughly divided into two kinds: wet mixing process and dry mixing process. The wet mixing process is to first mix and stir the adhesive, conductive agent and other substances, then add the active substance to stir and disperse fully, and finally add an appropriate amount of solvent to adjust the viscosity. The dry mixing process is the mixing of living matter, conductive agent and adhesive dry powder, adding an appropriate amount of solvent to moisten, adding solvent to disperse and break at high speed, diluting and adjusting viscosity.

Kneading homogenate process

Through the optimized kneading process, the dispersion effect of the paste can be improved, and the adhesion of the electrode can be effectively improved. The results show that with the optimized kneading process, the fineness of the paste is less than 20μm, the peeling strength of the pole piece is 9.87 N/m, and the wear rate of the pole piece is 0.61%.

Quality control

After the homogenization is completed, the quality of the slurry needs to be tested, including the concentration, pH value, viscosity and other indicators. Only the slurry that passes the quality inspection can enter the next step of the process.

Environmental control

In the process of batching and feeding, it is necessary to open and close the reactor frequently, which can easily lead to dust in the air falling into the slurry and causing pollution or glue sticking to the wall resulting in increased loss. Therefore, the control of the environment during the homogenization process is very important to ensure the purity and uniformity of the slurry.

Specific process flow

Incoming material confirmation & baking: the general conductive agent needs to be baked at about 120℃ for 8 hours, the binder PVDF needs to be baked at about 80℃ for 8 hours, the active substance (LFP, NCM, etc.), depending on the state of the incoming material and the process whether it needs to be baked and dried.

Configuration of PVDF adhesive solution: If the wet process is used, it is necessary to prepare PVDF adhesive solution (solute PVDF, solution NMP) in advance, and the quality of PVDF adhesive solution is crucial to the internal resistance and electrical performance of the battery.

Positive slurry: It is necessary to pay attention to the order of feeding (adding the active substance and the conductive agent slowly mixing, and then adding the glue liquid), feeding time, and feeding proportion, which should be strictly carried out according to the process. Secondly, it is necessary to strictly control the revolution and rotation speed of the equipment, the vacuum degree of stirring, and the temperature.

CONCLUSION

Through the above steps, the positive homogenization process ensures the uniform distribution and good bonding of the positive electrode material of the lithium battery, which is essential for the performance and life of the battery.

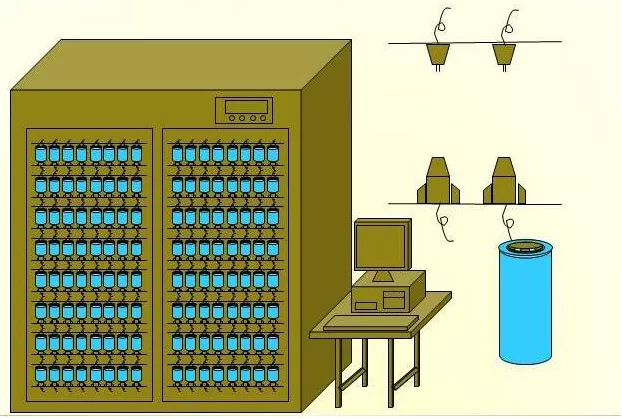

EPS BATTERY SERIES

The centralized power supply for fire emergency lighting is a kind of backup power supply equipment, which provides power guarantee for emergency lighting equipment to ensure that the on-site lighting equipment can operate normally in emergency situations such as fire. Provide a long-term backup power supply to meet the needs of the emergency lighting system.

Extended reading

THE ESSC Brand promise

Global supply

Our products sell well all over the world, covering many countries and regions, through the global logistics network, to provide customers with convenient purchasing experience.

Rigorous quality

We adhere to the highest quality control standards to ensure every product meets industry regulations and customer expectations, earning trust through consistent excellence.

Excellent service

With a customer-centric approach, we provide prompt responses, professional support, and personalized services, aiming to deliver the best user experience and long-term value.