Application and advantages of inorganic materials in lithium battery separator...

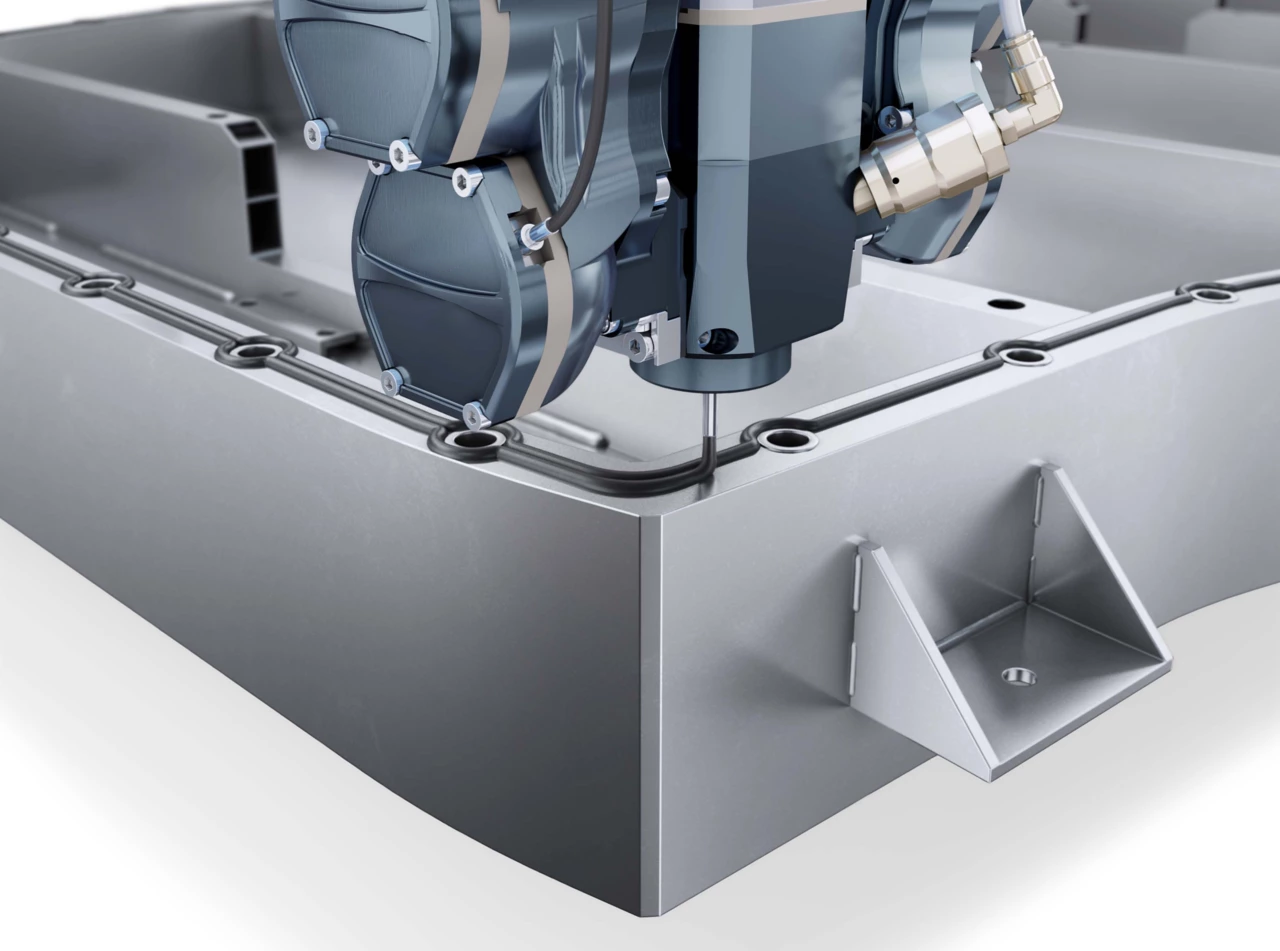

Polar ear ultrasonic welding

The positive and negative dispersed lugs are welded together into a piece, and the lugs need to be cut after the welding is completed.

Ultrasonic welding is a solid phase welding method, the welding between the welding parts through the acoustic high-frequency vibration and the static pressure between the workpiece to form the heat energy.

The welding quality of the electrode lug of lithium ion battery will directly affect the safety and rate performance of the battery. In the actual production, the electrode lug ultrasonic welding splice is composed of multiple solder joints, and the splicing quality is affected by the welding base material, the surface condition of the welding splice, the air pressure of the pressure mechanism, and the welding amplitude, energy, pressure, time and other factors.

process

Preparation

Clean the welding area of the electrode lug and electrode sheet to remove any oxide, oil or impurities and ensure that the welding surface is clean.

Choose the appropriate welding tip and protection sheet

The shape and size of the welding tip should be customized according to the material and thickness of the pole ear. If applicable, choose protective plates to avoid vibration or cracking of the auricle foil during welding.

Positioning and fixation

The pole lug should be accurately placed in the predetermined position of the electrode piece, and fixed with a special fixture or mold to ensure that the pole lug and the electrode piece are aligned and stable during welding.

Setting welding parameters

The parameters of the ultrasonic welding machine, including frequency (commonly 20kHz or 40kHz), amplitude, welding pressure, and welding time, are adjusted according to the material (such as aluminum, copper, or composite) and thickness of the pole ear.

Welding operation

Start the ultrasonic welding equipment, and the welding head applies pressure to the welding area with the assistance of the protective plate (if any), and starts high frequency vibration. The vibration generates local friction heat, which causes plastic deformation and intermolecular binding of the contact surface between the polar ear and the electrode sheet to form a firm welding spot.

Cooling and inspection

After the welding is completed, the welding area is allowed to cool naturally, and then the appearance and function inspection is carried out to ensure the welding quality, such as no cracks, virtual welding and other defects.

Precautions

Precautions include ensuring that the welding area is clean, using appropriate welding tips and guard plates, accurately positioning and securing the pole lugs, and adjusting the welding parameters to the material properties. In the welding process, the high frequency vibration of the welding tip is the key to realize the atomic resonance and bonding between the pole lug and the electrode sheet. The use of protective pieces can avoid damage to the polar ear foil during welding, while allowing proper adjustment of welding parameters to improve welding effect and firmness.

Home energy storage product series

A lithium battery pack for home energy storage systems, which is compatible with solar panels and the sun The inverter can work together with the power grid to power household appliances, and it can also be used as a For off grid systems.

Extended reading

Introduction of sealing material for joint parts of battery shell

Introduction of sealing material for joint parts of battery shell...

THE ESSC Brand promise

Global supply

Our products sell well all over the world, covering many countries and regions, through the global logistics network, to provide customers with convenient purchasing experience.

Rigorous quality

We adhere to the highest quality control standards to ensure every product meets industry regulations and customer expectations, earning trust through consistent excellence.

Excellent service

With a customer-centric approach, we provide prompt responses, professional support, and personalized services, aiming to deliver the best user experience and long-term value.