Product testing Product testing is a key link to ensure...

Learn more about low-speed car batteries

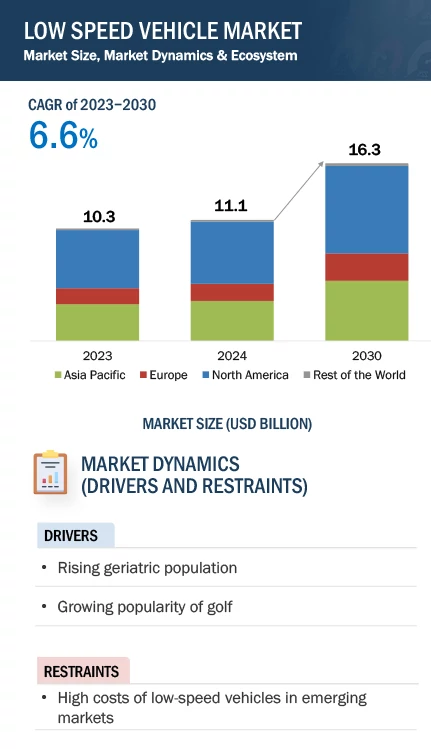

With the widespread application of low-speed electric vehicles in urban short-distance travel, community commuting, rural transportation, and logistics distribution, the importance of low-speed vehicle batteries is becoming increasingly evident. These batteries not only provide reliable power support for vehicles, but also attract attention due to their environmental protection, economic, and efficient features. In recent years, with the continuous advancement of technology, the endurance, safety, and charging efficiency of low-speed vehicle batteries have all improved significantly, further driving the expansion of their market demand and application scope. At the same time, government support policies for the new energy field have injected momentum into the development of the low-speed vehicle battery industry, making it an important link in the new energy industry.

Growth trend analysis

With the rapid expansion of the low-speed vehicle market, especially driven by the prevalence of electric vehicles, industrial applications, and the escalating demand for short-distance transportation, higher requirements have been imposed on the performance and reliability of low-speed vehicle batteries. A systematic comprehension of the entire life cycle of low-speed vehicle batteries, ranging from materials to application, not only enables the industry to secure an edge in future competition but also supports it in fulfilling diverse market demands, including the exploration of information management, material selection, manufacturing techniques, packaging technologies, and testing standards.

Learn more about low-speed car batteries

Product composition

Understanding the product composition of low-speed lithium batteries is crucial, because it not only determines the performance, life and safety of the battery, but also affects the battery's suitability and environmental protection. In practical applications, the selection and design of different battery components (such as positive and negative electrode materials, electrolyte, diaphragm, etc.) directly affect the energy density, power output and cycle life of the battery. The housing, packaging materials and thermal management system ensure the safety and reliability of the battery in a variety of environments. In addition, an in-depth understanding of the functions of the battery management system (BMS) and connectors helps optimize battery performance and ensure its safe use. Having detailed information about these components not only guides product development and technological innovation, but also enhances cost control and environmental sustainability.

To understand a battery, not only to understand its composition, but also to understand whether it can be extended to other places, and to have a certain understanding of its characteristics, development direction, and principle can allow you to understand this type of battery faster

Understanding the application scenarios of low-speed vehicle lithium batteries is crucial, because it is directly related to the optimization of battery design and performance. For example, different scenarios (such as logistics transportation, golf courses, industrial vehicles, etc.) have different requirements for battery energy density, cycle life, safety, and charging efficiency. Through in-depth study of these application scenarios, materials can be more targeted, processes can be improved, and more efficient management systems can be developed, thereby improving the efficiency of battery use and market competitiveness. In addition, this understanding will help drive breakthroughs in environmental, cost-effective and sustainable development of low-speed vehicle batteries to meet diverse market needs.

It is important to understand the production process of low-speed vehicle lithium batteries, because the process directly affects the performance, quality and production cost of the battery. Efficient production processes ensure optimal battery energy density, safety and life, while improving production consistency and yield. In addition, as market demand grows, advanced manufacturing processes such as automated production, coating and lamination technology can increase productivity, reduce costs, and reduce resource waste and carbon emissions. In-depth study of the production process helps to break through the technical bottleneck and promote the practical application of new materials, thus laying the foundation for the sustainable development and competitiveness of the industry.

The packaging and factory requirements of low-speed vehicle lithium batteries are crucial, because it not only involves the safe transportation and storage of products, but also directly affects the performance of the battery and the customer experience. Improper packaging may cause damage to the battery during transportation, such as short circuit, leakage, or rupture of the housing, resulting in safety hazards. At the same time, the factory inspection and requirements of the specification ensure that each batch of batteries meets the technical standards in terms of capacity, performance and consistency, reducing the risk of quality problems.

By optimizing the packaging design (such as shock-proof, moisture-proof, and STD-proof) and strictly performing the delivery inspection (such as charge and discharge test, appearance check, and safety performance evaluation), you can effectively improve the reliability and market competitiveness of products to meet the requirements of different environments and scenarios. This is of great significance for maintaining the reputation of enterprises and promoting the healthy development of the industry.

Battery performance testing is crucial for low-speed vehicle lithium batteries to ensure that the battery has stability and safety during use. By testing the battery's capacity, charge and discharge efficiency, cycle life, and performance under different environmental conditions, potential quality problems or safety hazards can be detected in time. This not only helps manufacturers optimize the battery design and production process, but also ensures that the final product can meet the expected performance standards in practical applications. In addition, rigorous performance testing improves product consistency and enhances customer trust, helping to enhance brand reputation and market competitiveness. Therefore, the battery performance test is a key step to ensure long-term stable operation of the battery and avoid the risk of failure.

low-speed car batteries

Low-speed vehicle battery is a kind of battery designed for low-speed electric vehicles, which has the characteristics of clean, environmental protection, high efficiency and economy, and is widely used in electric golf carts, low-speed electric vehicles (LSV), mobile vendors, campus transportation, cargo trucks and so on

Extended reading

Product packaging and delivery

Product packaging and delivery The packaging and delivery of battery...

Product information expansion

Product information expansion Understanding low-speed vehicle battery product information is...

Product composition

Low-speed lithium battery product composition Understanding the product composition of...

THE ESSC Brand promise

Global supply

Our products sell well all over the world, covering many countries and regions, through the global logistics network, to provide customers with convenient purchasing experience.

Rigorous quality

We adhere to the highest quality control standards to ensure every product meets industry regulations and customer expectations, earning trust through consistent excellence.

Excellent service

With a customer-centric approach, we provide prompt responses, professional support, and personalized services, aiming to deliver the best user experience and long-term value.