Electronic safety valve With the increasing global demand for renewable...

Method for measuring the thickness and porosity of diaphragm and electrode materials

In energy storage and conversion devices such as batteries, fuel cells, and supercapacitors, the properties of the separator and electrode materials have a crucial impact on the overall electrochemical performance. Measuring the thickness and porosity of these materials is an important step in characterizing their properties. Several commonly used measurement methods to help researchers and engineers accurately assess the thickness and porosity of diaphragm and electrode materials will be described.

thickness measurement method

Vernier caliper method of measurement

The vernier caliper is the most commonly used thickness measurement tool and is suitable for measuring samples with non-micron accuracy.

Clamp both sides of the vernier caliper to the edge of the sample and read the displayed thickness value. This method is simple and easy to perform, but for very thin materials such as battery separators, there may be some measurement error.

Microscopic measurement method

The thickness of the sample can be measured more accurately by observing the cross section of the material using light microscopy or scanning electron microscopy (SEM).

After cutting the sample into small pieces, its cross section was observed through a microscope and precise measurements were made using a microscope measuring tool. This method is suitable for thin film materials.

X-ray Diffraction (XRD)

The crystal structure information of the sample can be obtained by X-ray diffraction technology, and the thickness can be estimated by Bragg's law.

Although this method is commonly used in crystallographic studies, it can also be used in some cases to measure the thickness of thin films.

Laser interferometry

Laser interferometers can provide extremely high measurement accuracy and are suitable for micron and submicron thickness measurement.

Based on the principle of light wave interference, laser interferometry calculates the thickness of the sample by measuring the phase difference of the reflected light.

porosity measurement method

Mercury pressure method

Based on the non-wetting properties of mercury, the method uses pressure to press mercury into the pores of the sample and calculates the porosity from the volume pressed and the total volume of the sample.

This method is suitable for materials with high porosity, but it is less effective for smaller pore sizes.

Gas adsorption method

Using inert gases such as nitrogen or helium for adsorption experiments, the porosity can be calculated by measuring the amount of gas adsorbed on the sample surface and inside the pores.

Specific surface area analysis (such as the BET method) is the most commonly used gas adsorption method.

Liquid permeation method

The sample is immersed in the liquid and the degree of permeability of the liquid is observed to calculate the porosity.

This method is suitable for porous materials and is often used in combination with gas adsorption methods to obtain more comprehensive data.

Image analysis method

Images of the material were taken by scanning electron microscopy (SEM) or transmission electron microscopy (TEM), and the number and distribution of pores were analyzed by image processing software.

The porosity can be obtained by calculating the ratio of the total area of the pores to the total area of the material.

Conclusion

The thickness and porosity of the diaphragm and electrode materials are critical to the performance of batteries and energy storage devices. The selection of the appropriate measurement method should be determined according to the characteristics of the material, the required measurement accuracy and the experimental conditions. Accurate thickness and porosity measurements can provide important data support for the optimization and design of materials in electrochemical applications, helping to improve the working efficiency and life of equipment.

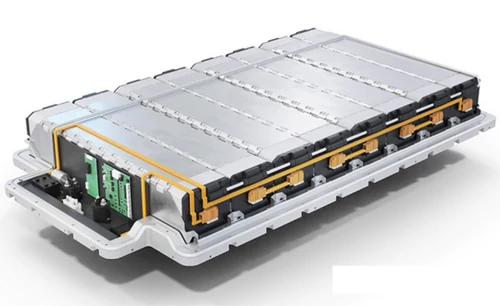

Home energy storage product series

A lithium battery pack for home energy storage systems, which is compatible with solar panels and the sun The inverter can work together with the power grid to power household appliances, and it can also be used as a For off grid systems.

Extended reading

What is the difference between dry single – pull process and dry double – pull process?

A highly integrated backup power solution for solar home energy...

Function analysis of battery pack housing

Function analysis of battery pack housing Battery pack housing is...

THE ESSC Brand promise

Global supply

Our products sell well all over the world, covering many countries and regions, through the global logistics network, to provide customers with convenient purchasing experience.

Rigorous quality

We adhere to the highest quality control standards to ensure every product meets industry regulations and customer expectations, earning trust through consistent excellence.

Excellent service

With a customer-centric approach, we provide prompt responses, professional support, and personalized services, aiming to deliver the best user experience and long-term value.