Input protection of charge control chip The input protection function...

Mechanical spring in mechanical locking device

In the design of DC charging piles and electric vehicle (EV) charging interfaces, mechanical springs are a key component responsible for providing stability, feedback and safety of the connection. The presence of a spring ensures the reliability of the charging connection and the ease of operation.

Main component

concept

Mechanical springs are devices made of elastic materials that can deform when subjected to external forces and return to their original shape when the external forces are removed. They are used in a wide variety of devices to provide resilience, cushioning, support and activation.

Working Principle

The working principle of mechanical springs is based on elasticity. When the spring is compressed or stretched, the atomic structure within it shifts slightly, creating potential energy. When the external force is removed, the spring releases this energy while returning to its original shape.

In the DC charging interface, the role of the spring is mainly reflected in the following points:

Connection stability: When the charging gun is inserted into the car interface, the spring will ensure good contact, reducing poor contact caused by shaking or external forces.

Automatic reset: When the charging gun is pulled out, the spring can automatically reset to ensure that the charging interface is ready to accept the next charging gun.

Adaptability: The spring can absorb certain vibration and shock, and protect the internal connecting parts in actual use.

Functions

The specific functions of the mechanical spring in the DC charging pile include:

Enhanced connection stability: Mechanical springs ensure good contact between the charging gun and the electric vehicle interface, reducing the risk of poor contact and preventing electrical failures caused by current changes.

Provide operational feedback: In the process of plugging and unplugging the charging gun, the resistance and release sense of the spring can provide clear operational feedback to the user and improve the user experience.

Shock absorption and buffering: During charging, the spring absorbs part of the vibration due to vehicle movement or uneven road surface, thus protecting the precision components of the charging interface.

Summary

Mechanical springs play a crucial role in the design of DC charging piles and electric vehicle charging interfaces. They provide multiple advantages such as connection stability, ease of operation, and vibration reduction, and are an important part of achieving efficient and safe charging solutions. In the future design, the selection of springs and their adaptation to the overall system should be considered comprehensively to improve the reliability and user experience of charging facilities.

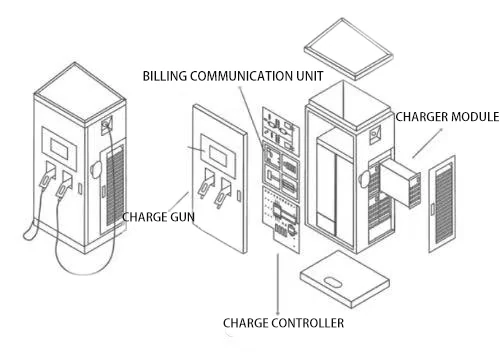

DC CHARGING PIlE SERIES

DC charging pile is an efficient charging facility for electric vehicles, which uses direct current (DC) to directly charge the vehicle battery, significantly reducing the charging time. Compared with traditional AC charging piles, DC charging piles are able to provide higher power output and can usually charge an EV to 80% of its capacity in 30 minutes, providing users with a convenient charging experience.

Extended reading

Introduction to magnetic bead of DC charging pile filter

Introduction to magnetic bead of DC charging pile filter The...

The introduction of DC charging pile overvoltage protection technology

The introduction of DC charging pile overvoltage protection technology Overvoltage...

What are the components of a DC charging pile

This paper will introduce the main components of DC charging...

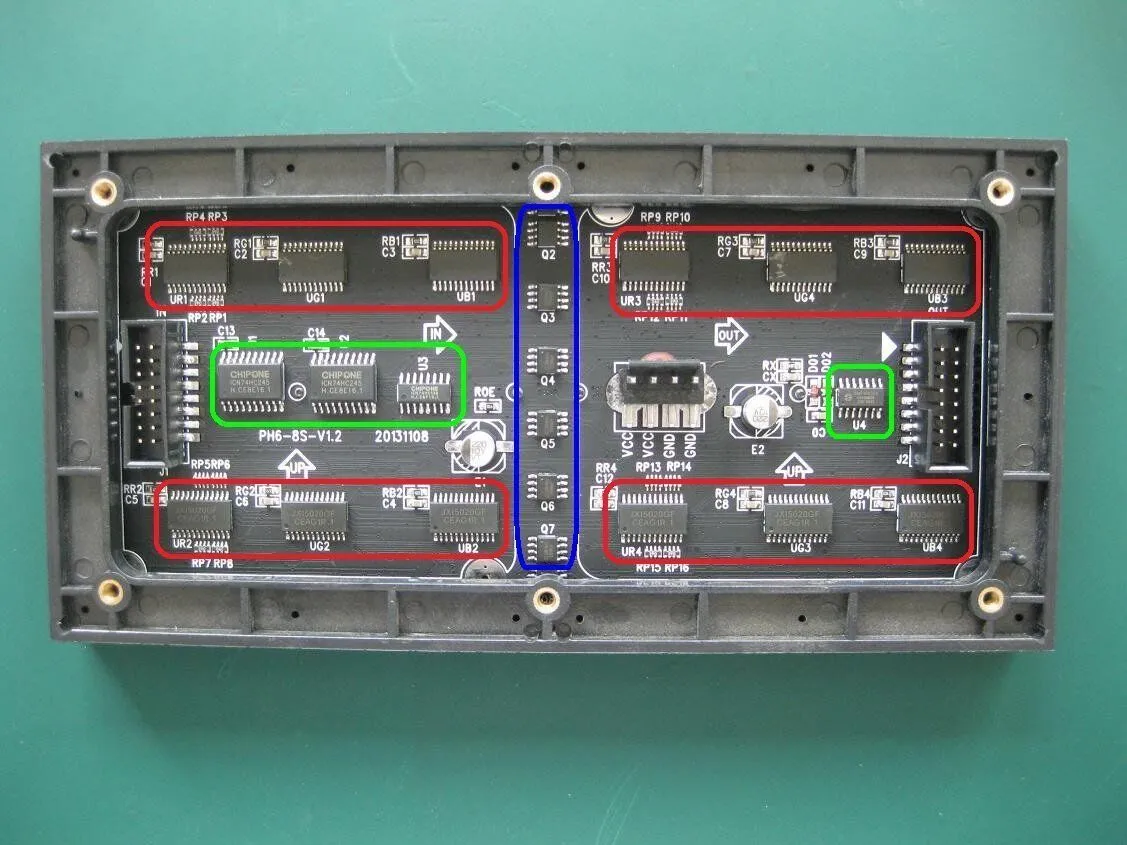

Dc charging pile display chip source driver

Dc charging pile display chip source driver Main component Concept:...

THE ESSC Brand promise

Global supply

Our products sell well all over the world, covering many countries and regions, through the global logistics network, to provide customers with convenient purchasing experience.

Rigorous quality

We adhere to the highest quality control standards to ensure every product meets industry regulations and customer expectations, earning trust through consistent excellence.

Excellent service

With a customer-centric approach, we provide prompt responses, professional support, and personalized services, aiming to deliver the best user experience and long-term value.