EPS inverter protection circuit analysis – overvoltage, overcurrent protection Emergency...

Materials for safety valves and pressure relief devices - stainless steel

In the design of battery cells, especially EPS (encapsulated power system) batteries, safety valves and pressure relief devices play a crucial role. Since the battery generates gas during charging and discharging and may cause internal pressure to rise, the existence of a safety valve and the choice of materials directly affect the safety and performance of the battery. The following is a detailed introduction to stainless steel as a safety valve and pressure relief device production material.

main content

summarize

Stainless steel is an alloy composed of iron, a small amount of carbon and at least 10.5% chromium, the addition of chromium provides good corrosion resistance, stainless steel is widely used in many fields, especially in the need for corrosion resistance, high temperature or wear resistance environment.

advantage

Corrosion resistance: Stainless steel has excellent corrosion resistance. The presence of chromium allows it to remain stable in acids, bases and other chemical media, and is particularly suitable for acidic or alkaline electrolyte environments in batteries.

High strength: Compared with other materials, stainless steel has higher strength and toughness, and can withstand high pressure and drastic temperature changes, which is especially important when the pressure is released in the battery.

Good thermal stability: stainless steel has a strong ability to change temperature and thermal shock, and can work for a long time in a high temperature environment without deformation or failure.

Recyclability: Stainless steel is an environmentally friendly material that can be recycled and meets the requirements of modern sustainable development.

Easy to process: Stainless steel has good processing properties and can be made into complex shapes to adapt to different design needs, such as various types of safety valves.

Specific applications in EPS batteries

Safety valve structure: Safety valve is usually made of stainless steel, including body, seat and stem components. These components must be able to work reliably under high pressure conditions and release pressure quickly when necessary.

Pressure release characteristics: When designing a safety valve, consider the ability of the valve to open quickly after reaching a preset pressure. Due to the high strength and fatigue resistance of stainless steel, this design ensures effectiveness in unexpected situations.

Sealing performance: The surface treatment and design optimization of stainless steel can achieve excellent sealing performance, avoid gas leakage, and ensure the stability of the battery internal environment.

Different types of stainless steel materials

304 Stainless Steel: This material is the most common choice of stainless steel, has good corrosion resistance and mechanical properties, and is suitable for most battery applications.

316 stainless steel: Compared to 304,316 stainless steel has stronger corrosion resistance, especially suitable for use in electrolytes containing chloride.

430 stainless steel: This martensitic stainless steel is more economical in price and suitable for battery components with less stringent corrosion requirements.

Design considerations of stainless steel safety valve

Preset opening pressure: According to the battery design needs, the opening pressure of the safety valve should be accurately designed to ensure that the gas can be released in time when the internal pressure exceeds the safe value.

Material thickness and shape: According to the strength and characteristics of stainless steel, the design needs to consider the thickness and shape of the material to ensure the pressure resistance of the valve.

Surface treatment: Appropriate surface treatment (such as polishing, sandblasting or coating) to improve its corrosion resistance and aesthetics, and reduce the impact of chemical reactions inside the battery on the valve.

CONCLUSION

Because of its excellent corrosion resistance, high strength and processability, stainless steel has become the ideal material for EPS cell safety valves and pressure relief devices. Through reasonable design and manufacture, stainless steel valves can provide the necessary safety guarantee during battery use. With the continuous development of battery technology, the demand and application of stainless steel materials will continue to increase, promoting the safety and reliability of the battery industry.

EPS BATTERY SERIES

The centralized power supply for fire emergency lighting is a kind of backup power supply equipment, which provides power guarantee for emergency lighting equipment to ensure that the on-site lighting equipment can operate normally in emergency situations such as fire. Provide a long-term backup power supply to meet the needs of the emergency lighting system.

Extended reading

Materials for safety valves and pressure relief devices – Polypropylene (PP)

Materials for safety valves and pressure relief devices – Polypropylene...

This section describes the battery in the EPS battery unit

This section describes the battery in the EPS battery unit...

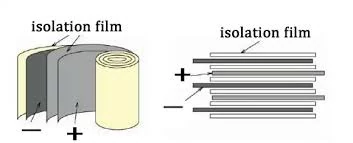

Isolation film material of EPS cell monomer: polymer

Isolation film material of EPS cell monomer: polymer In the...

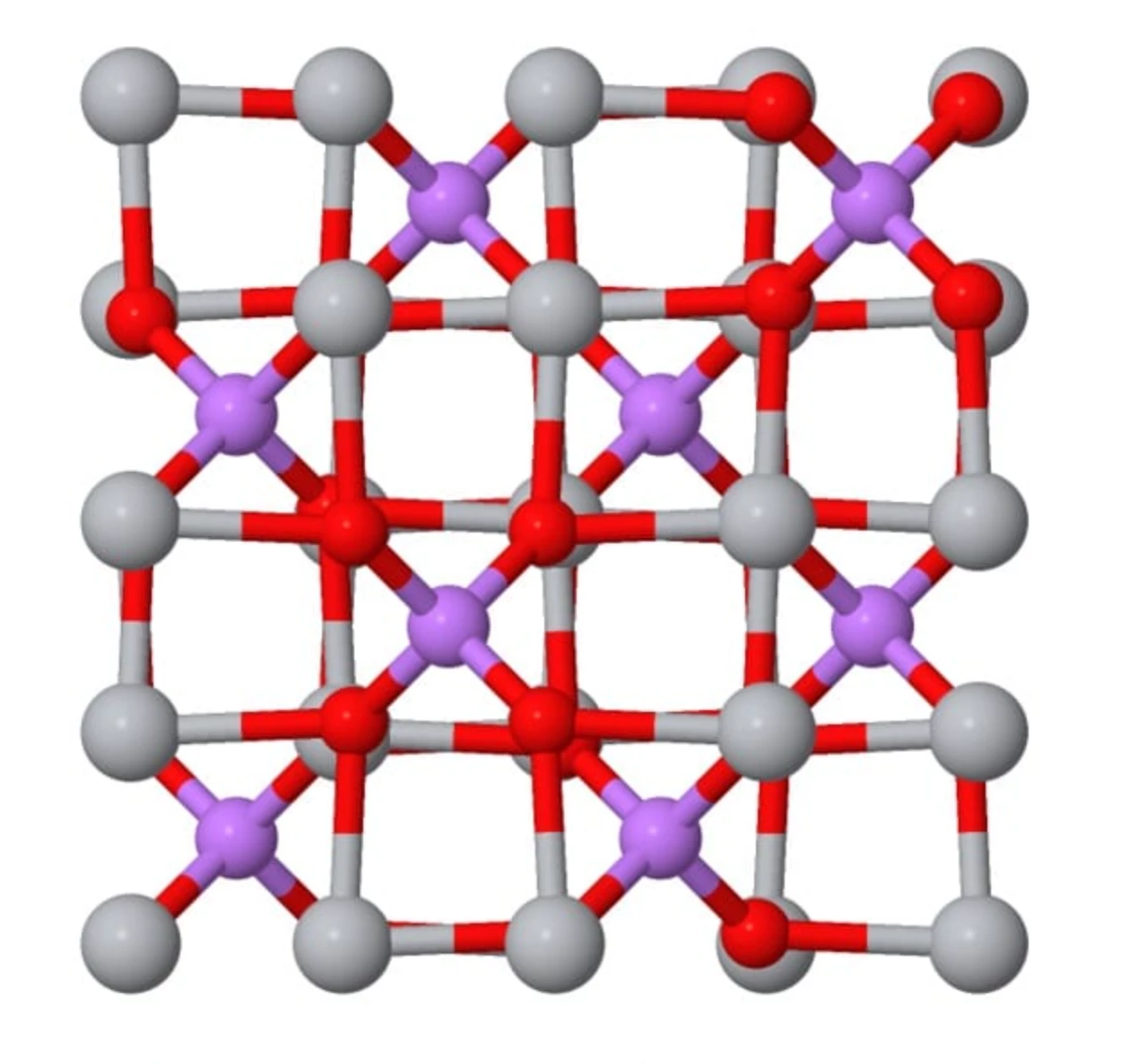

Negative electrode materials in EPS battery cell

negative electrode materials in EPS battery cell The negative electrode...

THE ESSC Brand promise

Global supply

Our products sell well all over the world, covering many countries and regions, through the global logistics network, to provide customers with convenient purchasing experience.

Rigorous quality

We adhere to the highest quality control standards to ensure every product meets industry regulations and customer expectations, earning trust through consistent excellence.

Excellent service

With a customer-centric approach, we provide prompt responses, professional support, and personalized services, aiming to deliver the best user experience and long-term value.