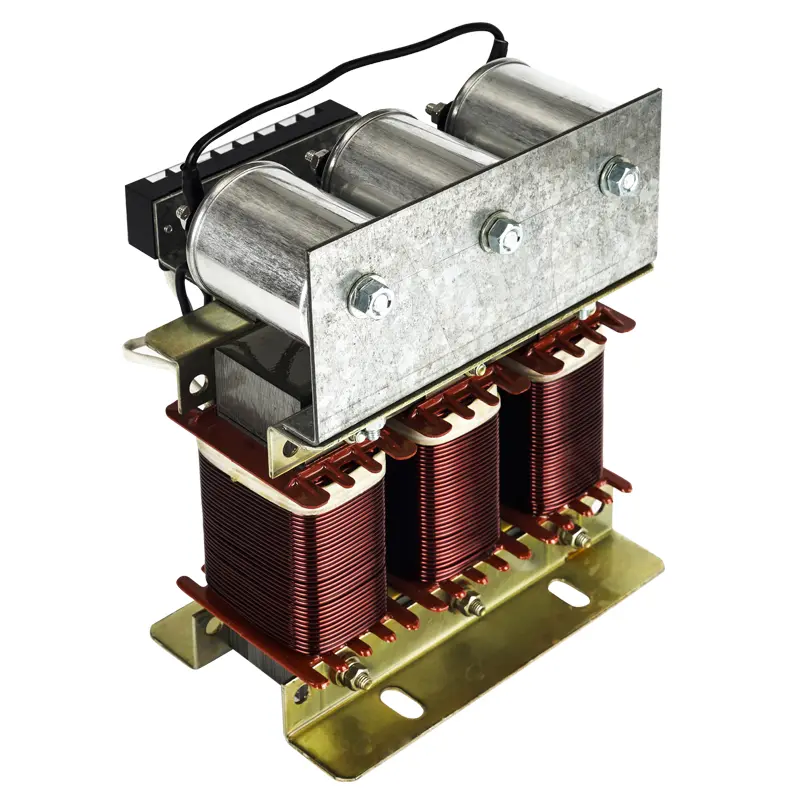

EPS inverter output filter analysis In the emergency power supply...

Materials for safety valves and pressure relief devices - Polypropylene (PP)

In the EPS (Encapsulated Power System) battery cell, safety valves and pressure relief devices are key components to prevent excessive pressure inside the battery. Polypropylene (PP), as a thermoplastic with good chemical stability and handling properties, is increasingly used in the manufacturing of these safety components. The following will describe in detail the application and advantages of polypropylene in the safety valve and pressure relief device of EPS battery cells.

main content

Basic features

Polypropylene is a common thermoplastic polymer with the following characteristics:

Chemical stability: polypropylene has good chemical resistance, can resist many acids, bases and solvents, suitable for the changeable chemical environment inside the battery.

Lightweight: The low density of polypropylene makes it ideal for lightweight materials, reducing the weight of the overall battery cell.

Excellent mechanical properties: polypropylene has good tensile strength and toughness, suitable for the design of safety valves under certain pressure.

Good thermal stability: Polypropylene has a melting point of about 160°C, which is suitable for use in the temperature range that may be generated in batteries.

Recyclability: Polypropylene can be recycled, in line with environmental requirements, in line with sustainable material selection standards.

Specific application in EPS battery

The structure and function of the safety valve: The safety valve is an important safety component of the battery, which is used to release excessive internal pressure. Due to its excellent sealing performance and elasticity, polypropylene is suitable for the manufacture of valve seals and valve bodies.

Pressure release device: The pressure release device can quickly open when the internal pressure of the battery exceeds the safety threshold, releasing pressure to avoid battery explosion or leakage. The polypropylene material has been designed with appropriate opening pressure and rebound characteristics in mind to ensure a rapid response in emergency situations.

Adaptability to the internal environment of the battery: The good resistance of polypropylene to battery electrolytes and chemicals ensures its stability in long-term use, avoiding the aging and failure of the material.

Advantages

Low cost: The production cost of polypropylene is relatively low, making the use of safety valves and pressure relief devices made of polypropylene reduce the overall manufacturing cost of the battery.

Excellent formability: polypropylene is suitable for injection molding and extrusion molding, and can easily manufacture complex safety valves to meet the needs of different battery designs.

Good electrical insulation: polypropylene itself is a good electrical insulator, which is particularly important in battery cells to prevent short circuits and electrical safety hazards.

Thermal isolation performance: polypropylene can effectively block heat conduction during battery operation, reducing the risk of heat transfer with surrounding components.

CONCLUSION

Due to its excellent chemical stability, light weight, high strength and multi-functional molding characteristics, polypropylene has become an important material for EPS cell safety valve and pressure release device.

EPS BATTERY SERIES

The centralized power supply for fire emergency lighting is a kind of backup power supply equipment, which provides power guarantee for emergency lighting equipment to ensure that the on-site lighting equipment can operate normally in emergency situations such as fire. Provide a long-term backup power supply to meet the needs of the emergency lighting system.

Extended reading

EPS charging interface introduction

EPS charging interface The EPS (Emergency Power Supply) charging interface...

Battery shell material of EPS battery unit

battery shell material of EPS battery unit The battery housing...

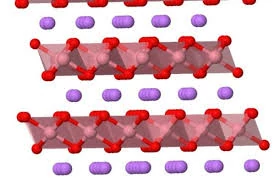

Introduction of positive electrode materials in EPS battery cell

Introduction of positive electrode materials in EPS battery cell Today,...

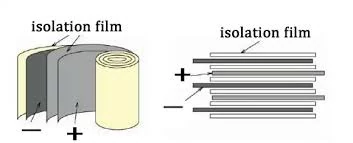

Isolation film material of EPS cell monomer: polymer

Isolation film material of EPS cell monomer: polymer In the...

Materials for safety valves and pressure relief devices – Polypropylene (PP)

Materials for safety valves and pressure relief devices – Polypropylene...

THE ESSC Brand promise

Global supply

Our products sell well all over the world, covering many countries and regions, through the global logistics network, to provide customers with convenient purchasing experience.

Rigorous quality

We adhere to the highest quality control standards to ensure every product meets industry regulations and customer expectations, earning trust through consistent excellence.

Excellent service

With a customer-centric approach, we provide prompt responses, professional support, and personalized services, aiming to deliver the best user experience and long-term value.