Application and advantages of polyethylene in lithium battery separator With...

Material for welding terminals

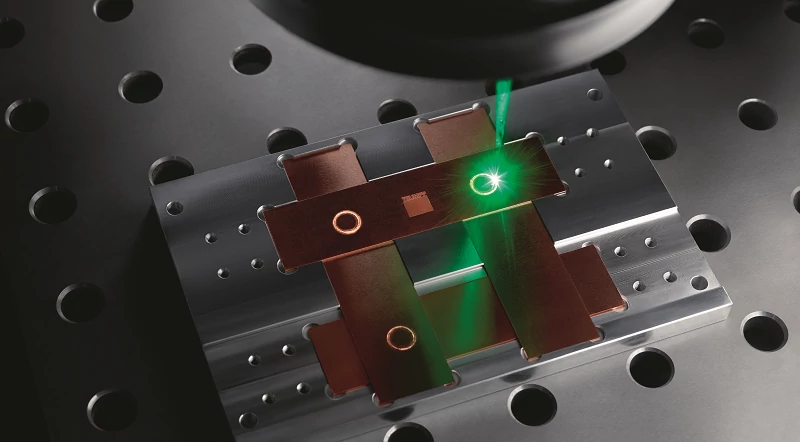

Welding terminals are of great importance in the electrical and electronic industry, where they provide reliable mechanical support and electrical interfaces for electrical connections. In many applications, the selection of appropriate welding terminal materials is a key factor in ensuring the performance, durability, and safety of electrical connections. This article will describe common materials, material properties, application scenarios and their importance in design choices for soldered terminals.

Common types of welding terminal materials

Copper

Characteristics: Copper has excellent electrical conductivity, good mechanical strength and high heat resistance, and is the most commonly used material for welding terminals. It is usually coated to increase corrosion resistance. Coating treatment: Common treatments include tin plating, nickel plating and silver plating, of which tin plating is the most common, which can prevent oxidation and maintain good solderability.

Brass

Characteristics: Brass is an alloy composed of copper and zinc, which has good workability and relatively strong corrosion resistance. Brass is often used in low to medium current connection applications due to its economy and good electrical conductivity.

Phosphor Bronze

Properties: Phosphor bronze is an alloy of copper, tin and phosphorus with excellent elasticity, wear resistance and fatigue resistance. It is commonly used in application scenarios that require high resilience and durability.

Stainless Steel

Properties: Stainless steel has strong corrosion resistance and high strength, but low conductivity. It is usually used in harsh environmental requirements and corrosion protection conditions.

Aluminum

Characteristics: Aluminum is light and has good electrical conductivity, but its weldability is poor. As a result, in scenarios where lightweight design is required, there are specific engagement treatments to improve contact performance.

The importance of material selection

The selection of appropriate welding terminal materials is essential to ensure the reliability, efficiency, and safety of electrical connections. Key considerations include:

Electrical conductivity: The electrical conductivity of the material directly affects the electrical properties of the terminals. In high current applications, highly conductive materials such as copper are ideal.

Mechanical properties: The terminal material is required to have sufficient strength to resist mechanical stress, especially under vibration or impact conditions to maintain the integrity of the connection.

Corrosion resistance: Terminal materials used in aggressive environments must be able to resist oxidation and chemical attack.

Thermal properties: The material should have good heat resistance and be able to work in high temperature environments without deformation or failure.

Conclusion

Material selection of welding terminals is critical to ensure the performance and reliability of electrical connection components. The electrical conductivity, mechanical properties, corrosion resistance and thermal properties of materials are all factors that must be comprehensively considered in the design and selection. With the advancement of technology and the expansion of application fields, the innovation and optimization of welding terminal materials will continue to promote the development of electrical connection technology and provide support and guarantee for more industrial and electronic applications.

Home energy storage product series

A lithium battery pack for home energy storage systems, which is compatible with solar panels and the sun The inverter can work together with the power grid to power household appliances, and it can also be used as a For off grid systems.

Extended reading

How to test the static voltage of a single battery

How to test the static voltage of a single battery...

Preliminary Soldering before Housing

Preliminary Soldering before Housing The good battery core is loaded...

THE ESSC Brand promise

Global supply

Our products sell well all over the world, covering many countries and regions, through the global logistics network, to provide customers with convenient purchasing experience.

Rigorous quality

We adhere to the highest quality control standards to ensure every product meets industry regulations and customer expectations, earning trust through consistent excellence.

Excellent service

With a customer-centric approach, we provide prompt responses, professional support, and personalized services, aiming to deliver the best user experience and long-term value.