Application scenarios of cloud platform connectivity The ability of the...

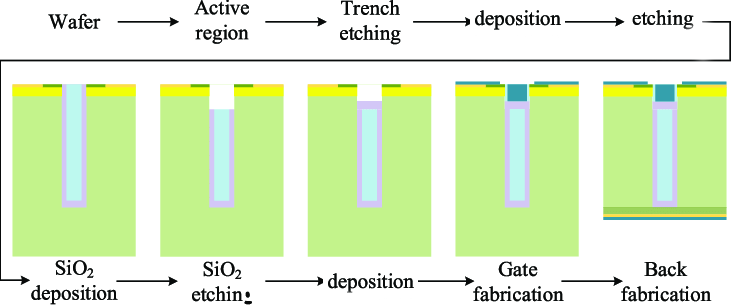

Main production process of IGBT

The inverter in uninterruptible power supply (UPS) system is the key component to convert DC to AC, and the IGBT is one of the core components in the inverter. The performance and reliability of IGBTs directly affect the efficiency of the entire power electronic system. The following will introduce the main production process of IGBT, focusing on the analysis of wafer manufacturing, electrode formation, packaging and testing and quality control of four key links.

Main production process

Wafer manufacturing

Doping: Different impurities are incorporated into silicon crystals by ion implantation and other methods to form N-type and P-type regions to form PN structures.

Oxidation and patterning: A thin layer of silicon oxide is formed on the wafer surface, and the device structure is defined by the lithography process.

Forming Electrodes

Metal deposition: The use of evaporation or sputtering technology to deposit metals (such as aluminum or titanium) on the wafer surface to form source, drain and gate electrodes.

Sintering treatment: The metal electrode is fixed at high temperature to ensure good contact.

Encapsulation

Cutting package: The produced wafer is cut into a single IGBT chip, the chip is placed in the package, the packaging material is injected and cured.

Testing and quality control

Functional testing: Every manufactured IGBT must undergo rigorous functional and performance testing to confirm its electrical parameters, reliability and durability.

Calibration: Calibration and grading of IGBTs that meet the standard for different application requirements.

CONCLUSION

The production process of IGBT is a systematic engineering, covering many links from wafer fabrication to electrode formation, packaging, testing and quality control. Technical progress and process optimization at each stage have an important impact on the performance and reliability of IGBT.

UPS BATTERY SERIES

UPS (Uninterruptible Power Supply) batteries are an important component of power supply systems designed to provide stable power support for electronic devices.

Extended reading

UPS Remote Monitoring Connection Mode 4: Cloud Platform Connection

UPS remote monitoring connection mode 4: Cloud Platform connection With...

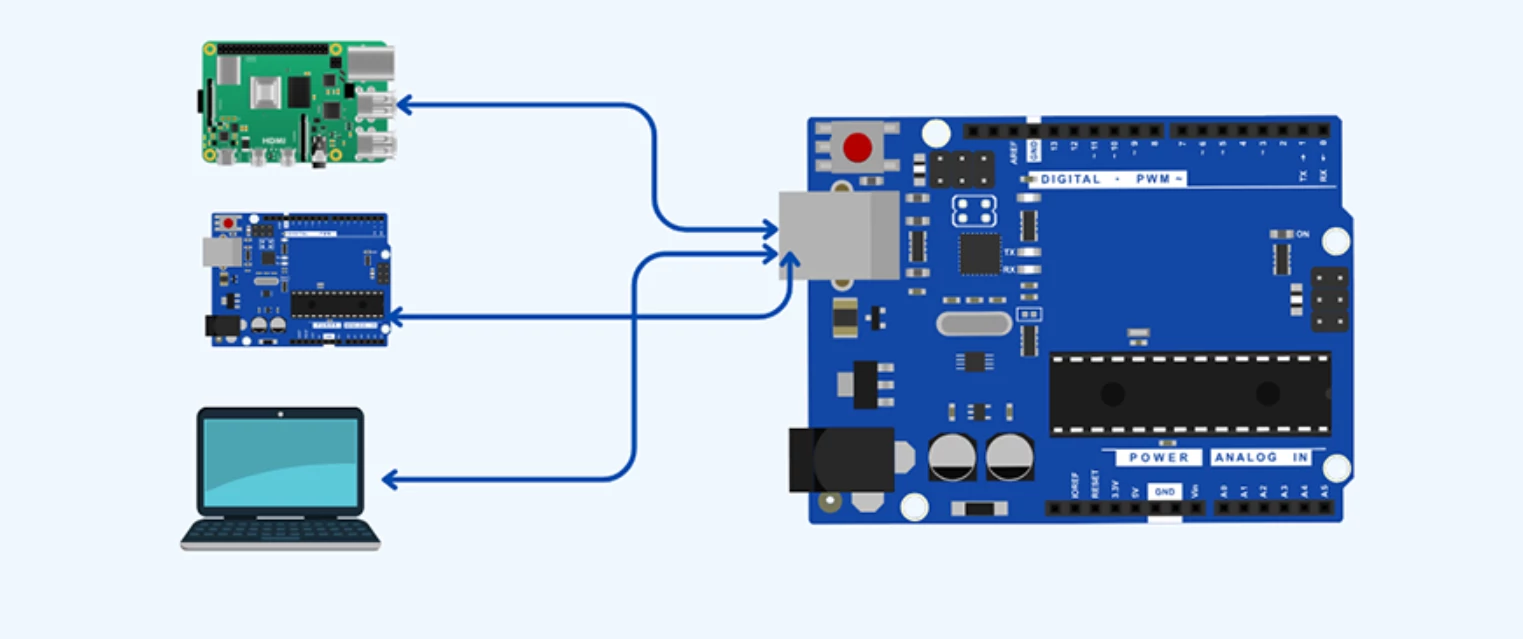

UPS Remote Monitoring Connection 3: USB Connection

UPS remote monitoring connection 3: USB connection In today’s rapidly...

Advantages and Application Scenarios of Serial Port Connection

Advantages and application scenarios of serial port connection Using RS-232...

UPS Remote Monitoring Connection Mode 2 — Serial Port Connection (RS-232/RS-485)

UPS remote monitoring connection mode 2 — Serial port connection...

UPS Eemote Monitoring Connection 1- Network Connection (Ethernet/Wi-Fi)

UPS remote monitoring connection 1- Network connection (Ethernet/Wi-Fi) In modern...

THE ESSC Brand promise

Global supply

Our products sell well all over the world, covering many countries and regions, through the global logistics network, to provide customers with convenient purchasing experience.

Rigorous quality

We adhere to the highest quality control standards to ensure every product meets industry regulations and customer expectations, earning trust through consistent excellence.

Excellent service

With a customer-centric approach, we provide prompt responses, professional support, and personalized services, aiming to deliver the best user experience and long-term value.

.webp)