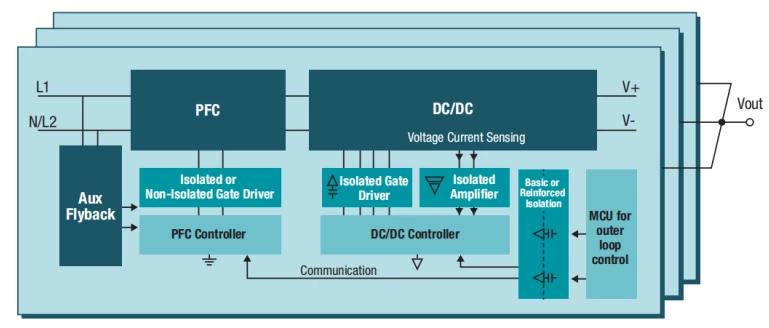

The input voltage of the ground DC charging pile adopts...

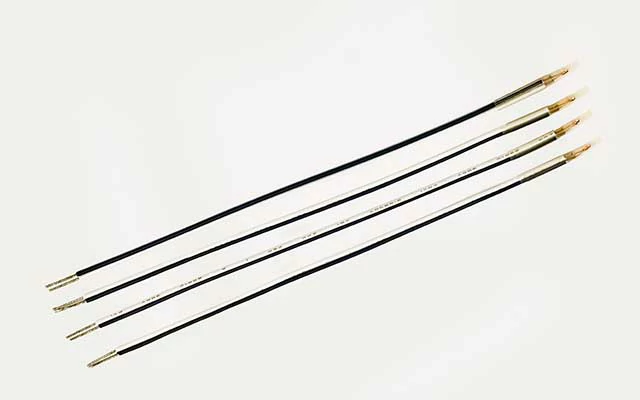

Locking pin and locking bolt of the gun head mechanical locking device

Main component

concept

Locking pin: A small rod, usually made of metal or reinforced plastic, is used to form a mechanical lock between the charging gun and the electric vehicle, thus ensuring the stability of the connection.

Locking bolt: Similar to a locking pin, a locking bolt is a component that can be locked and released by tightening or loosening, usually with higher load carrying capacity and tensile strength.

design principle

Locking process: When the user inserts the charging gun into the vehicle charging port, the locking pin or locking bolt automatically enters the locking position via a spring or mechanical device. This process is often accompanied by a "click" sound, indicating that the user has successfully connected.

Unlocking process: When charging is complete, the user presses the operation button or pulls the release lever, and the locking pin is popped out or the bolt is loosened, allowing the charging gun to be freely pulled out.

Apply

Dc charging gun: In a DC charging gun, the locking pin or locking bolt ensures that the contact point is always in good contact while charging, providing a steady current.

Electric vehicle interface: In the charging port of the electric vehicle, the relevant locking mechanism works closely with the locking system of the charging gun to prevent human or collision disconnection in the charging state.

Summary

Locking pins or locking bolts play a vital role in the design of DC charging piles, not only increasing the safety of charging, but also improving the user experience. As electric vehicles and charging technologies continue to evolve, the design of locking mechanisms is also being optimized to accommodate higher safety standards and user needs. These technological advances will provide safer, more convenient and more reliable solutions for the charging industry.

DC CHARGING PIlE SERIES

DC charging pile is an efficient charging facility for electric vehicles, which uses direct current (DC) to directly charge the vehicle battery, significantly reducing the charging time. Compared with traditional AC charging piles, DC charging piles are able to provide higher power output and can usually charge an EV to 80% of its capacity in 30 minutes, providing users with a convenient charging experience.

Extended reading

What are the components of a temperature sensor

What are the components of a temperature sensor The temperature...

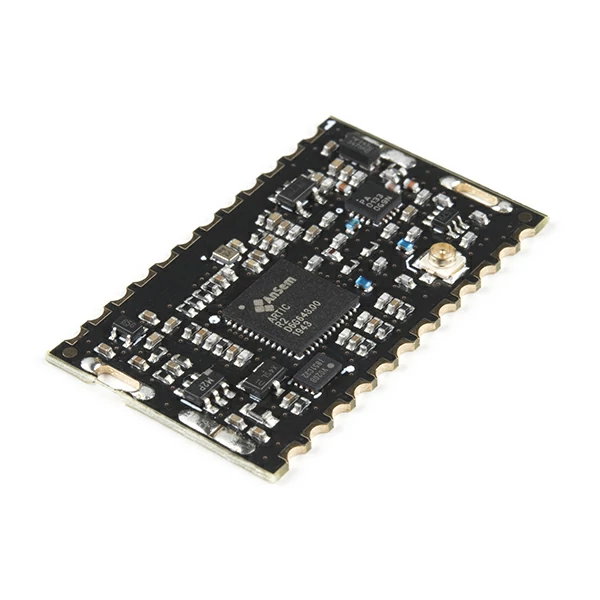

The communication module in card reader is introduced

The communication module in card reader is introduced Main component...

BRM Gateway in DC charging pile communication charging module

BRM Gateway in DC charging pile communication charging module Main...

About security modules in card readers

About security modules in card readers Main component Security module...

DC charging pile meter safety and protection components

DC charging pile meter safety and protection components Main component...

THE ESSC Brand promise

Global supply

Our products sell well all over the world, covering many countries and regions, through the global logistics network, to provide customers with convenient purchasing experience.

Rigorous quality

We adhere to the highest quality control standards to ensure every product meets industry regulations and customer expectations, earning trust through consistent excellence.

Excellent service

With a customer-centric approach, we provide prompt responses, professional support, and personalized services, aiming to deliver the best user experience and long-term value.